Sportique

Established Member

Thanks to Mailee for introducing me to Bridge City in an earlier post - seeing the Joint Master Pro set me to thinking "what-if ....?"

Well I enjoy engineering challenges (in a very simple way!) and although my version does not have a tilting blade - maybe that will come? - it does work very well.

This is certainly not everyone's cuppa tea - the tool/jig has serious size limitations - and without a tilting blade will only make vertical cuts - but I am sure it will be very useful in box making and other similar scale items. The cuts are easy, QUIET, clean and square. I am suprised how little effort is needed for one-push cuts.

I was fortunate in having a spare Japanese thin-kerf, pull-cut blade.

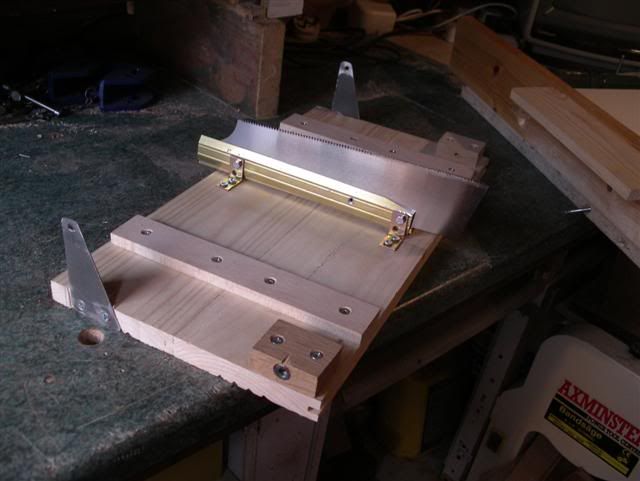

So, first I drilled two mounting holes in the blade, then mounted the blade onto a board using angle plates and some alluminium stiffening pieces. (Sorry no WIP).

Then built the table and cut a kerf slot in the centre. This top is supported by side pieces to give clearance for the blade mounting board and mechanism. Two swivel brackets were fabricated and fitted to the blade mounting board in line with the front (near) end of the blade as a pivot.

The side pieces were slotted to take M5 bolts/knobs to allow for vertical adjustment of the back of the blade (far end). This allows the blade to drop below the table, and rise to 30mm at the tip. The height adjustment bolts are threaded into mounting blocks holding thread inserts.

Then a sliding fence was made up - rather than ploughing mitre slots I fitted side bars to slide along the sides of the table - first I made sure the table and blade were all square to each other. The fence is fitted to a sliding board to give plenty of support and stability when sliding the fence forward.

Finally a couple of pieces of softwood were fitted along the bottom of the side pieces to facilitate clamping the whole thing to the bench - this is essential.

I hope you enjoyed that? (Thanks for heads up on Bridge City Mailee)

Dave

Well I enjoy engineering challenges (in a very simple way!) and although my version does not have a tilting blade - maybe that will come? - it does work very well.

This is certainly not everyone's cuppa tea - the tool/jig has serious size limitations - and without a tilting blade will only make vertical cuts - but I am sure it will be very useful in box making and other similar scale items. The cuts are easy, QUIET, clean and square. I am suprised how little effort is needed for one-push cuts.

I was fortunate in having a spare Japanese thin-kerf, pull-cut blade.

So, first I drilled two mounting holes in the blade, then mounted the blade onto a board using angle plates and some alluminium stiffening pieces. (Sorry no WIP).

Then built the table and cut a kerf slot in the centre. This top is supported by side pieces to give clearance for the blade mounting board and mechanism. Two swivel brackets were fabricated and fitted to the blade mounting board in line with the front (near) end of the blade as a pivot.

The side pieces were slotted to take M5 bolts/knobs to allow for vertical adjustment of the back of the blade (far end). This allows the blade to drop below the table, and rise to 30mm at the tip. The height adjustment bolts are threaded into mounting blocks holding thread inserts.

Then a sliding fence was made up - rather than ploughing mitre slots I fitted side bars to slide along the sides of the table - first I made sure the table and blade were all square to each other. The fence is fitted to a sliding board to give plenty of support and stability when sliding the fence forward.

Finally a couple of pieces of softwood were fitted along the bottom of the side pieces to facilitate clamping the whole thing to the bench - this is essential.

I hope you enjoyed that? (Thanks for heads up on Bridge City Mailee)

Dave