Scouse

Established Member

With reference to Jimi’s recent thread regarding his purchase of an infill plane in need of some work, it was noted that some old tools are worth restoring to working condition, for their historic as much as their financial value.

With that in mind I thought it might be an interesting diversion to revisit some of the old, very rusty stuff I have bought over the past year, chiefly from carboot sales, and have a look at them in working order.

Don’t get me wrong, there are no museum pieces or things of any beauty, and I’m partial to patina, so there has been little polishing.

Everything, however, was originally a rusty pile, and has now been dismantled into component parts; de-rusted, cleaned, lubricated and put in place next to their working counterparts.

Nothing here has any value or significance in the history of tools, but I feel it would be a shame not to put back to work that which would otherwise be scrapped and lost forever.

It’s worth noting that nothing has cost more than a fiver with the exception of the Union pillar drill and the 98 and 99 planes.

So, first an overview of the mess that constitutes the dirty bench, so called because it is dirty.

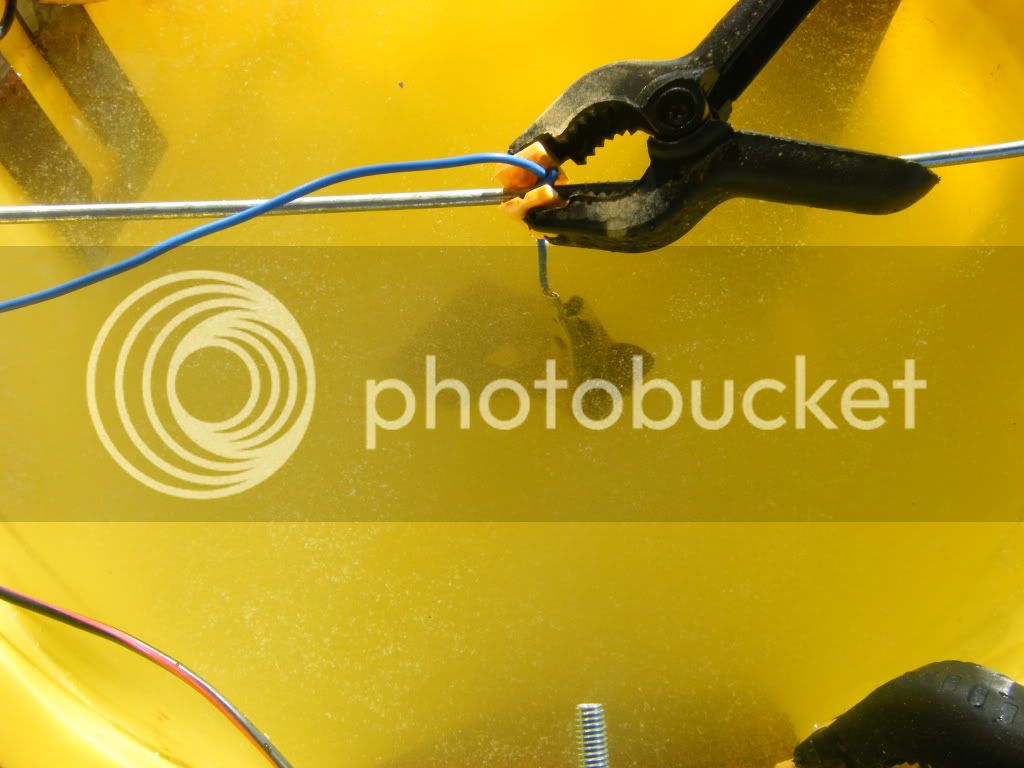

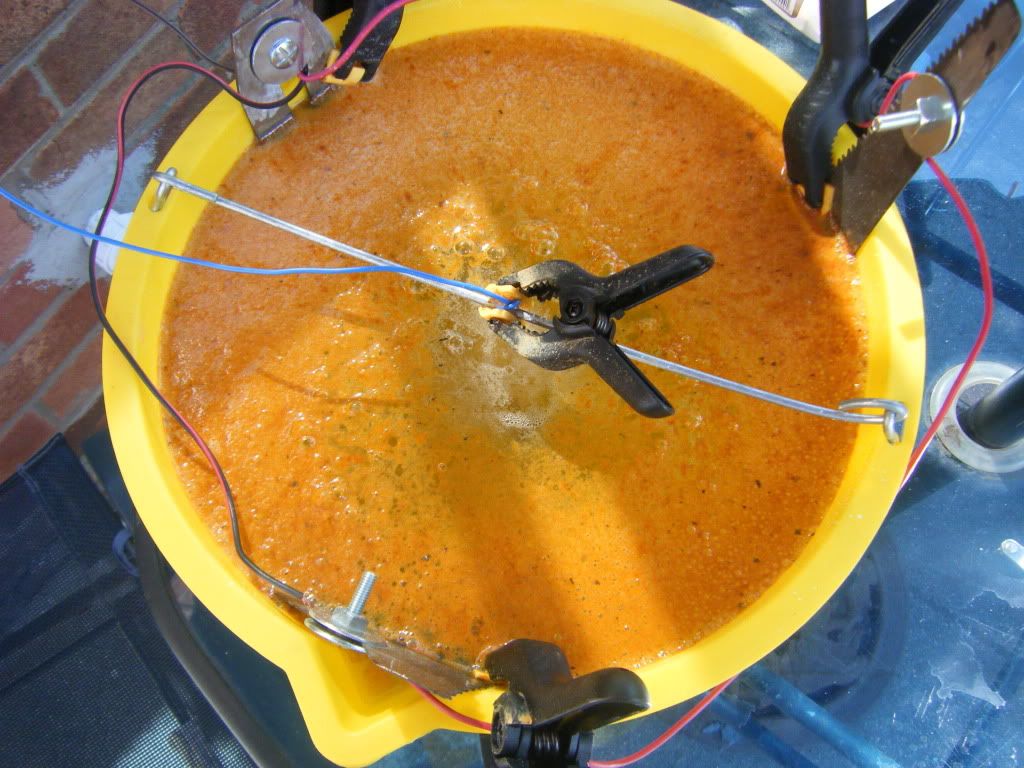

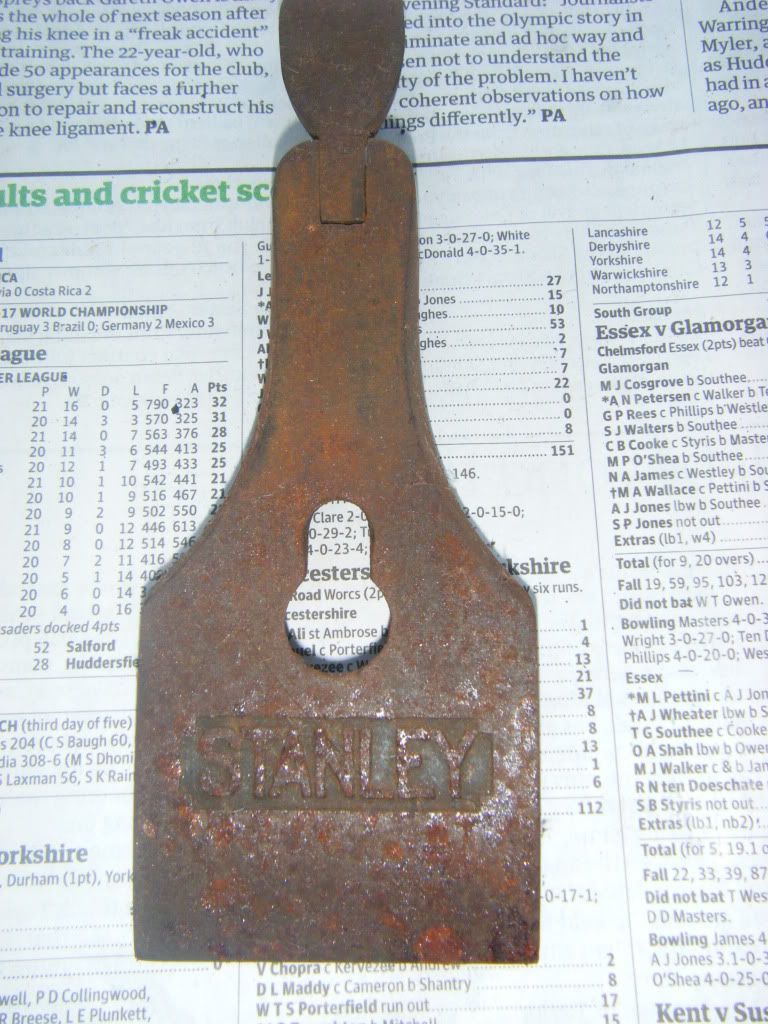

These three pictures show a number of projects in various states of undress. The big drill was done a while back, but was seized and fit for nothing. Works well now. 2 old saws, one un-named one Tyzack, both old apparently, judging by the flat split nuts; I’ve not had the bottle to pull them apart yet. The 2 planes, a Stanley no4 type 13 from 1925-28 and a W.S. are both waiting to go into an electrolysis bath for de-rusting, which is my current (no pun intended!) pet project. There are also a couple of drills in pieces, a Millers Falls no1, and no120a breast drill, the frames of which are both also for the leccy bath. The stuff in the dog bowls is the cleaned small parts from the drills and the Stanley brace next to the lamp.

Three drills, all three Millers Falls; an early no5, a no2, and a no85 missing the handle. The no5 has just been cleaned and works fine, the no2 represents the good bits from two terribly rusty tools. The frame has been stripped and repainted, the handle was wrecked and had to be sanded and re varnished, hence the odd colour, the handle from the donor drill is now the crank handle for the Union. The no85 was not in great shape, it too has been stripped and put back together, but the handle disintegrated during the renovation, so I need to turn a new one when time allows.

More on the wall; a Leytool drill, which had been packed with grease so it would not turn, three wrenches (2 king **** Abingdon, 1 Ford) and two braces, a Millers Falls no 22 and the smaller one by Thos. Wales and Son, about whom I can find no information.

Three saw sets, the Stanley 42X was in as new shape when I got it, so only needed oil. The Eclipses, both very dirty and one rusty are, despite their similar shapes very different. The one on the left is iron/steel and has a thin tooth pushy bit, the one on the right is brass with a much thicker thingy.

Next, a Stanley no4, another type 13 from ’25-’28, with a period Sweetheart blade. Cleaned, de rusted and had the sole flattened. Front knob has been replaced with one I turned from walnut I’ve kept the old one safe; it had split due to the absence of a reinforcing ring which was cast into the body from type 14 onwards. I might make a new handle too since the original still has the remnants of the decal.

A pair of side rebate planes, Stanley 98 and 99, de-rusted and left as original. The 98 is older by about 30 years. I would like to get a couple of replacement blades though.

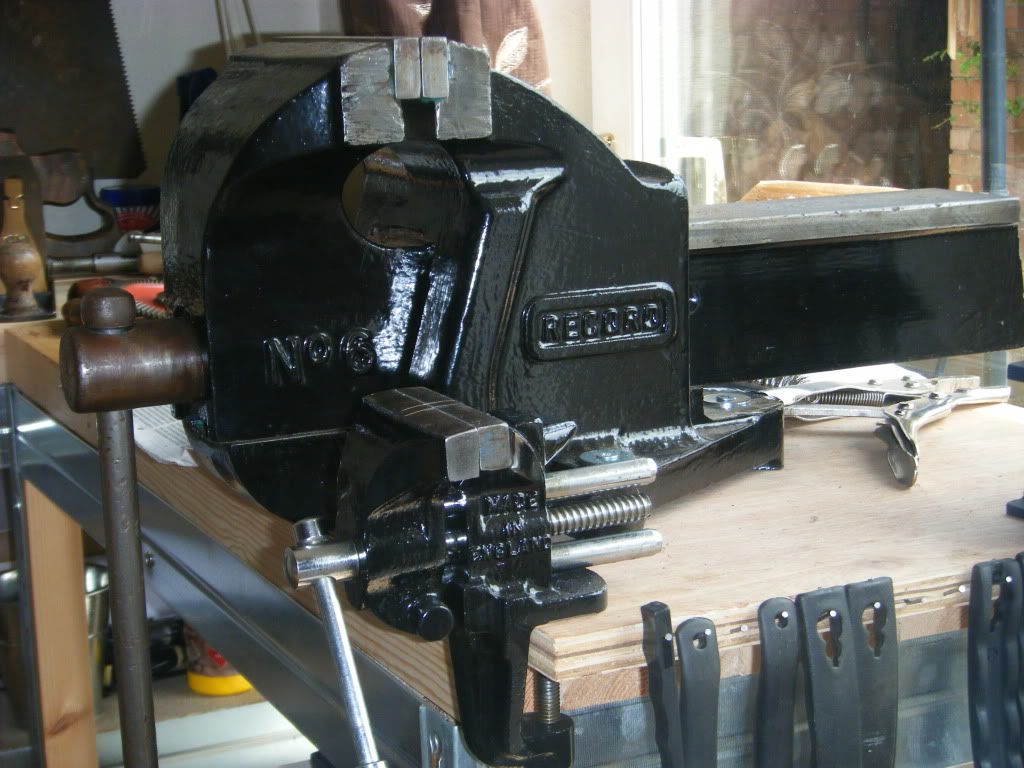

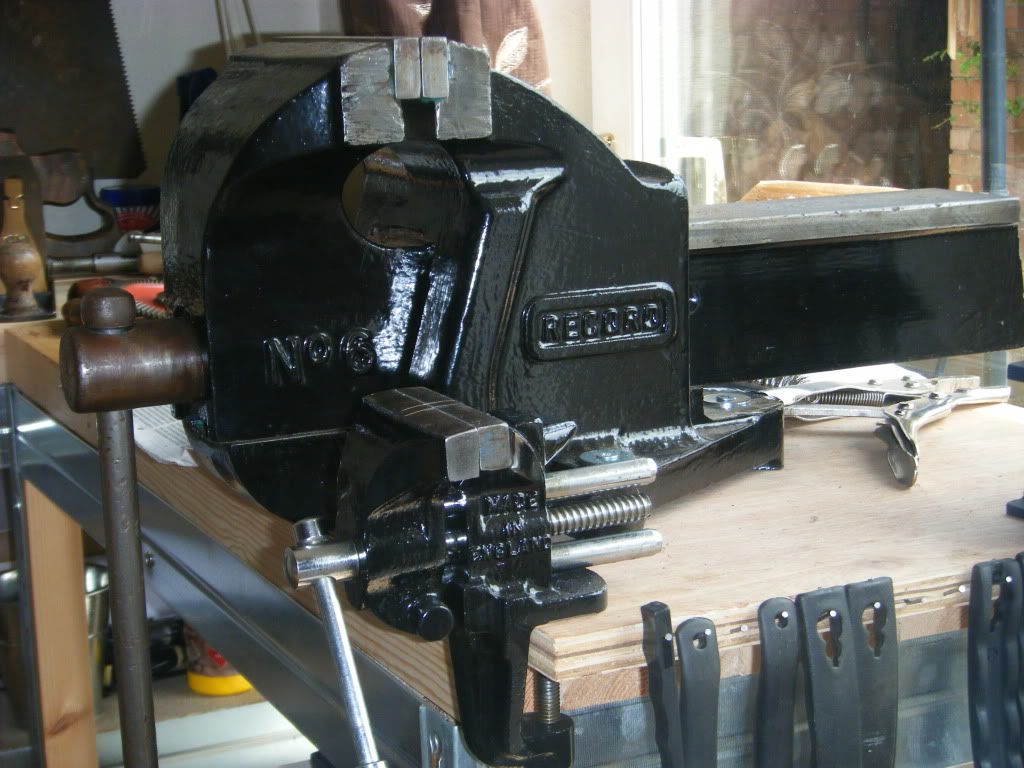

Finally vices. The Record no6 and the tiny Woden X260 Titan were both rusty and seized, especially the Record which I had to heat to free. It’s a monster, maybe a bit too big for my needs, but never mind. I’d not seen a Titan before and was about to buy a Record Imp, but this was, in spite of its size more substantial. Below them is a Woden saw vice, rusted and covered in some sort of oil with the consistency of a really bad cold. It was mounted on a bit of ply, but I’ve got a bigger board for it, just need to put it on.

I hope this post hasn’t looked like a gloat; I intended it to act as a bit of inspiration, that even the most far gone tool may have a decent one underneath all the rust, and that with a bit of elbow grease it is possible to build a reasonable number of good tools for not much money.

I’ll treat this as a work in progress and add to it as I finish more stuff.

El.

With that in mind I thought it might be an interesting diversion to revisit some of the old, very rusty stuff I have bought over the past year, chiefly from carboot sales, and have a look at them in working order.

Don’t get me wrong, there are no museum pieces or things of any beauty, and I’m partial to patina, so there has been little polishing.

Everything, however, was originally a rusty pile, and has now been dismantled into component parts; de-rusted, cleaned, lubricated and put in place next to their working counterparts.

Nothing here has any value or significance in the history of tools, but I feel it would be a shame not to put back to work that which would otherwise be scrapped and lost forever.

It’s worth noting that nothing has cost more than a fiver with the exception of the Union pillar drill and the 98 and 99 planes.

So, first an overview of the mess that constitutes the dirty bench, so called because it is dirty.

These three pictures show a number of projects in various states of undress. The big drill was done a while back, but was seized and fit for nothing. Works well now. 2 old saws, one un-named one Tyzack, both old apparently, judging by the flat split nuts; I’ve not had the bottle to pull them apart yet. The 2 planes, a Stanley no4 type 13 from 1925-28 and a W.S. are both waiting to go into an electrolysis bath for de-rusting, which is my current (no pun intended!) pet project. There are also a couple of drills in pieces, a Millers Falls no1, and no120a breast drill, the frames of which are both also for the leccy bath. The stuff in the dog bowls is the cleaned small parts from the drills and the Stanley brace next to the lamp.

Three drills, all three Millers Falls; an early no5, a no2, and a no85 missing the handle. The no5 has just been cleaned and works fine, the no2 represents the good bits from two terribly rusty tools. The frame has been stripped and repainted, the handle was wrecked and had to be sanded and re varnished, hence the odd colour, the handle from the donor drill is now the crank handle for the Union. The no85 was not in great shape, it too has been stripped and put back together, but the handle disintegrated during the renovation, so I need to turn a new one when time allows.

More on the wall; a Leytool drill, which had been packed with grease so it would not turn, three wrenches (2 king **** Abingdon, 1 Ford) and two braces, a Millers Falls no 22 and the smaller one by Thos. Wales and Son, about whom I can find no information.

Three saw sets, the Stanley 42X was in as new shape when I got it, so only needed oil. The Eclipses, both very dirty and one rusty are, despite their similar shapes very different. The one on the left is iron/steel and has a thin tooth pushy bit, the one on the right is brass with a much thicker thingy.

Next, a Stanley no4, another type 13 from ’25-’28, with a period Sweetheart blade. Cleaned, de rusted and had the sole flattened. Front knob has been replaced with one I turned from walnut I’ve kept the old one safe; it had split due to the absence of a reinforcing ring which was cast into the body from type 14 onwards. I might make a new handle too since the original still has the remnants of the decal.

A pair of side rebate planes, Stanley 98 and 99, de-rusted and left as original. The 98 is older by about 30 years. I would like to get a couple of replacement blades though.

Finally vices. The Record no6 and the tiny Woden X260 Titan were both rusty and seized, especially the Record which I had to heat to free. It’s a monster, maybe a bit too big for my needs, but never mind. I’d not seen a Titan before and was about to buy a Record Imp, but this was, in spite of its size more substantial. Below them is a Woden saw vice, rusted and covered in some sort of oil with the consistency of a really bad cold. It was mounted on a bit of ply, but I’ve got a bigger board for it, just need to put it on.

I hope this post hasn’t looked like a gloat; I intended it to act as a bit of inspiration, that even the most far gone tool may have a decent one underneath all the rust, and that with a bit of elbow grease it is possible to build a reasonable number of good tools for not much money.

I’ll treat this as a work in progress and add to it as I finish more stuff.

El.