Hi, I got this saw recently with a job lot of old tools and whilst its nothing special, I fancied returning it to a better state.

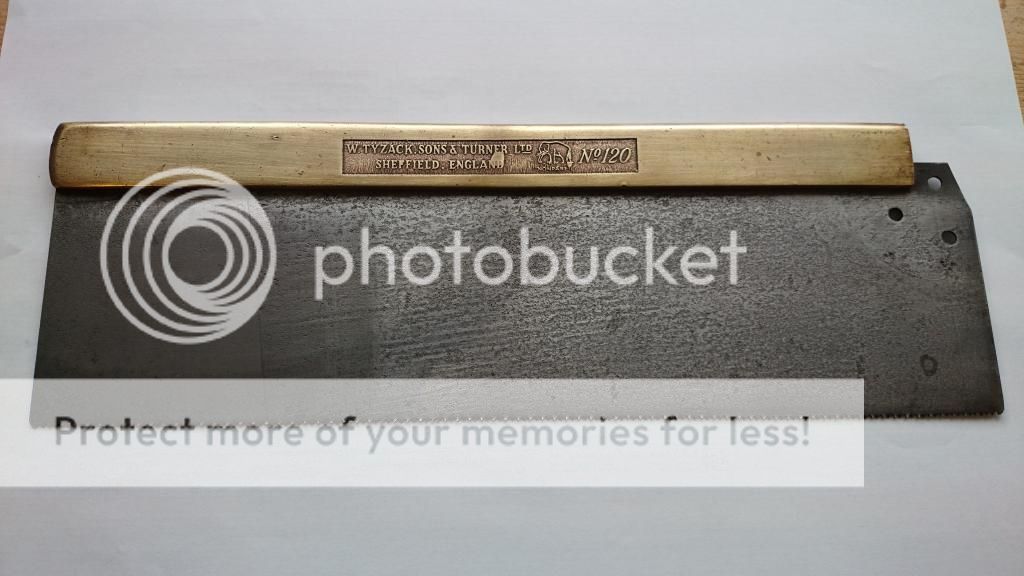

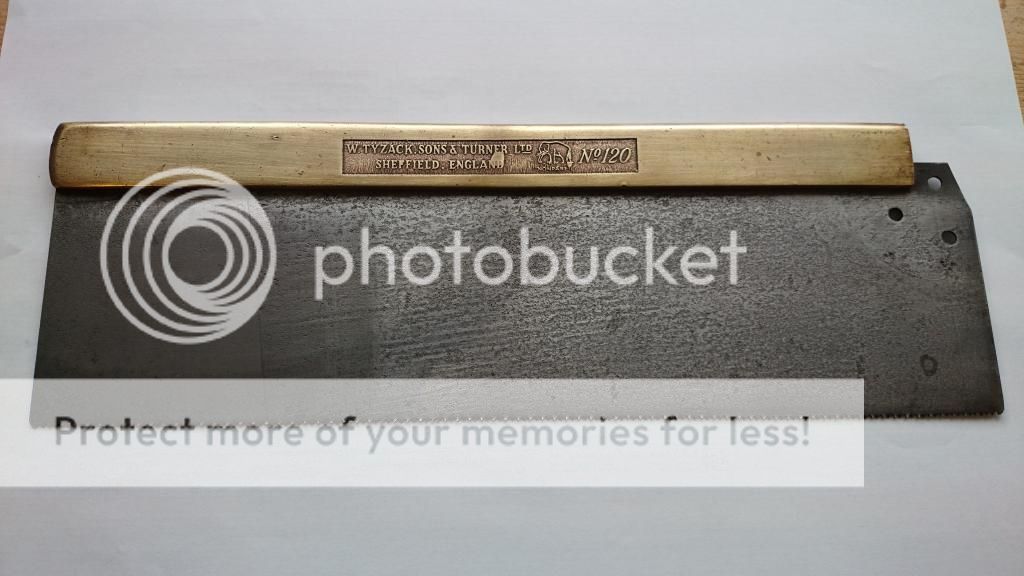

Now, the blade was a bit corroded and needs a sharpen, but its not terrible. I cleaned it up a bit, but I don't think I can get it much better than it is now:

There are noticeable marks on it and still evidence of old pitting. So first questions relate to the blade: Will the lack of smoothness and shiny finish affect its operation? How easy are blades to replace, bearing in mind the brass back is quite nice - can they be replaced easily? Where can I get it sharpened and or the blade replaced?

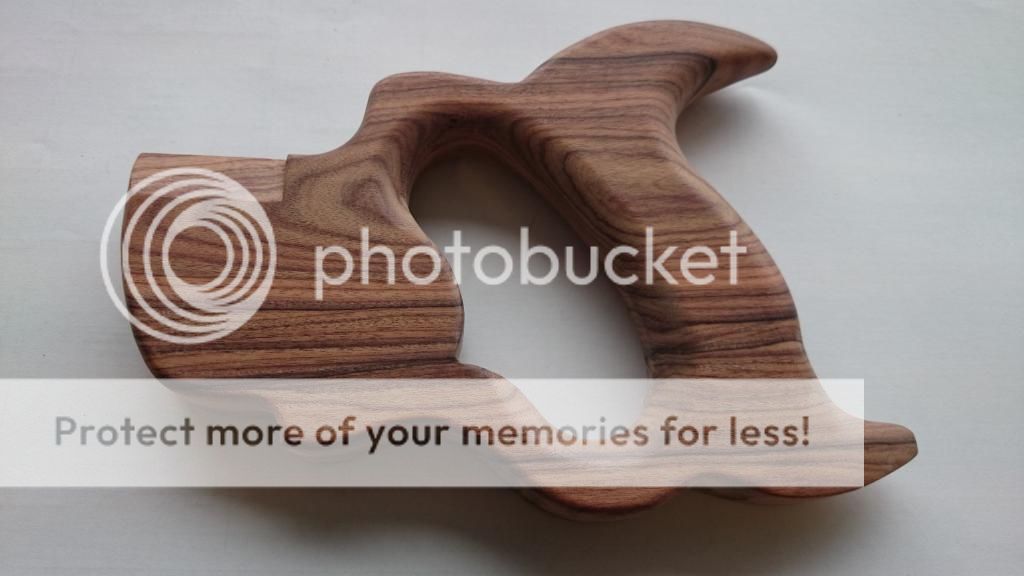

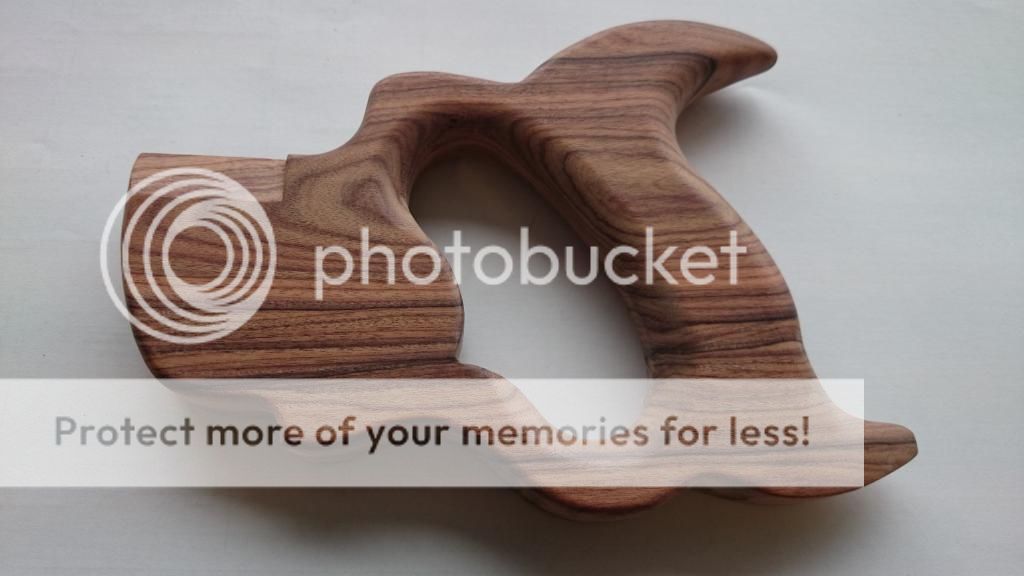

The handle was pretty crappy and broken, so I copied it and remade it in rosewood:

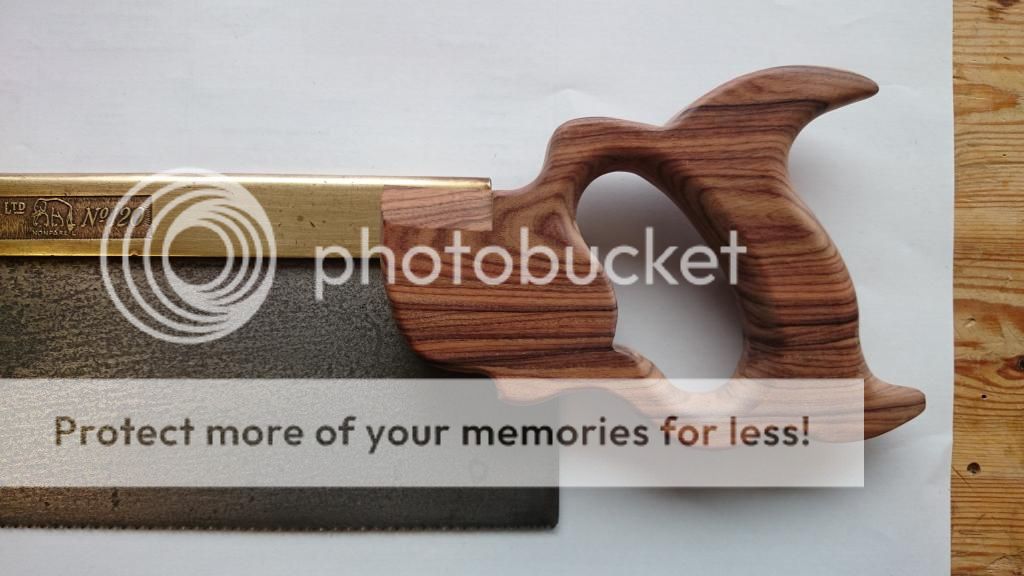

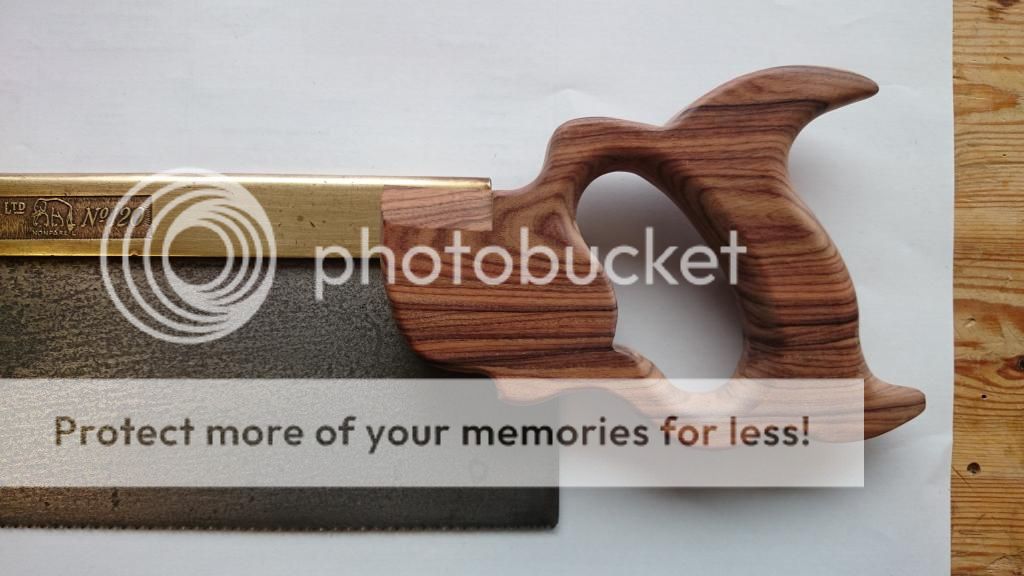

I am pretty pleased how it came out for a first attempt. Here is the handle laying on the saw so you can see how it will look:

I think now the new handle and the shiny back will make the old blade look crappy...what do you think?

Now, the blade was a bit corroded and needs a sharpen, but its not terrible. I cleaned it up a bit, but I don't think I can get it much better than it is now:

There are noticeable marks on it and still evidence of old pitting. So first questions relate to the blade: Will the lack of smoothness and shiny finish affect its operation? How easy are blades to replace, bearing in mind the brass back is quite nice - can they be replaced easily? Where can I get it sharpened and or the blade replaced?

The handle was pretty crappy and broken, so I copied it and remade it in rosewood:

I am pretty pleased how it came out for a first attempt. Here is the handle laying on the saw so you can see how it will look:

I think now the new handle and the shiny back will make the old blade look crappy...what do you think?