Aled Dafis

Established Member

Hi i'm about to start building an oak sideboard for a mate of mine as a wedding gift (I was one of the best men). He's been married just over a year, and I'm making good progress, the drawings are just about done. :roll:

This project started out with my wife offering them a coffee table as a gift, which they were very pleased with, and they'd have a think about the style - this was a few months before they were due to get married so I thought that I'd have plenty of time to get it done. Months passed, and I asked them if they'd thought about the coffee table, they had, and came to the conclusion that they didn't have enough room in the middle of the lounge for a coffee table, but they had a small alcove that would take a sideboard. :shock: :shock: I couldn't really say NO could I? So I took a deep breath and agreed with a smile on my face and a though going through my head of "what the hell have let myself in for?"

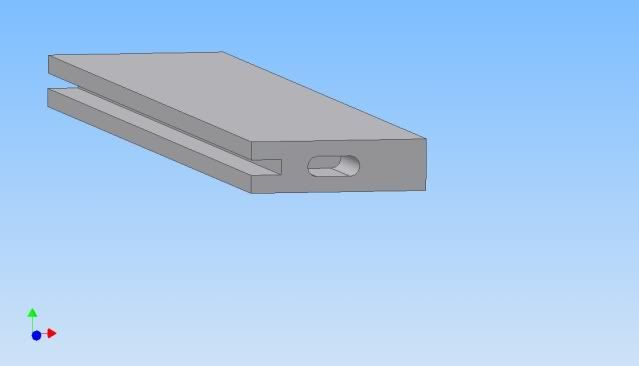

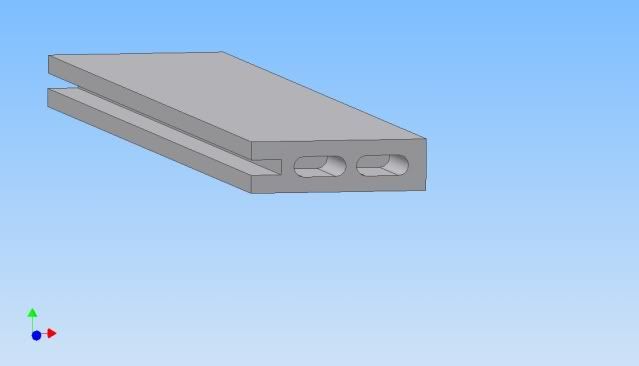

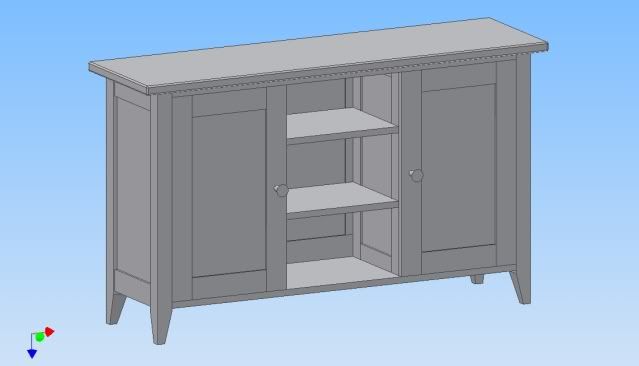

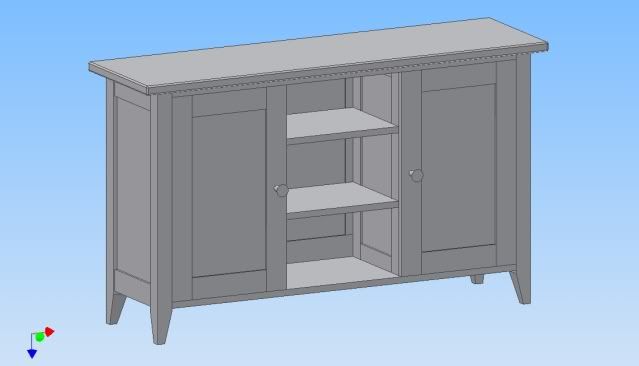

Here's a pic of the 3D model so far, I can't get my head around sketchup, so this is produced in Autodesk Inventor.

I used to use Inventor a few years ago when I was an engineer, and I've finally managed to get a free 20 seat licence for school, it really is a fantastic CAD package that's easy to learn and very powerful in what it can do.

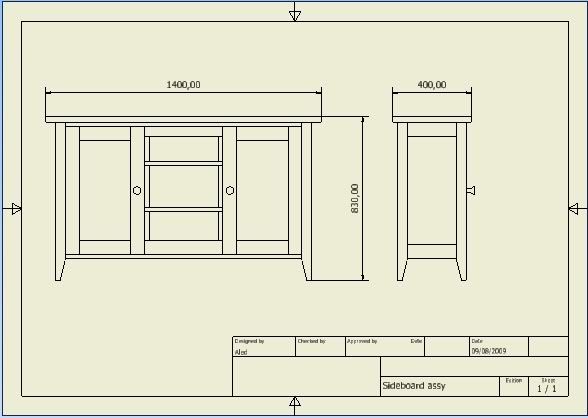

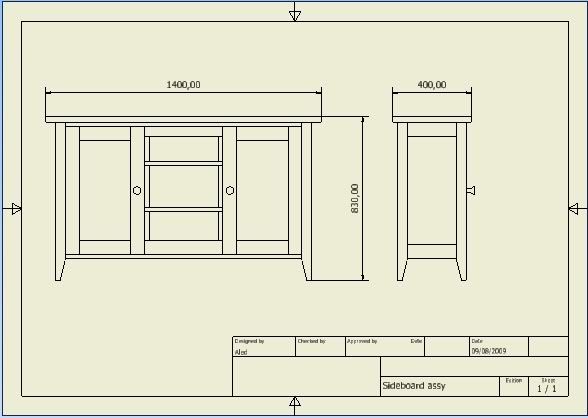

And here's the orthographic drawing.

Cheers

Aled

This project started out with my wife offering them a coffee table as a gift, which they were very pleased with, and they'd have a think about the style - this was a few months before they were due to get married so I thought that I'd have plenty of time to get it done. Months passed, and I asked them if they'd thought about the coffee table, they had, and came to the conclusion that they didn't have enough room in the middle of the lounge for a coffee table, but they had a small alcove that would take a sideboard. :shock: :shock: I couldn't really say NO could I? So I took a deep breath and agreed with a smile on my face and a though going through my head of "what the hell have let myself in for?"

Here's a pic of the 3D model so far, I can't get my head around sketchup, so this is produced in Autodesk Inventor.

I used to use Inventor a few years ago when I was an engineer, and I've finally managed to get a free 20 seat licence for school, it really is a fantastic CAD package that's easy to learn and very powerful in what it can do.

And here's the orthographic drawing.

Cheers

Aled