Thanks for your kind words guys.

Some details; sorry, I'm new around here and didn't realise that etiquette required the posting of details of how a project was conceived and made!

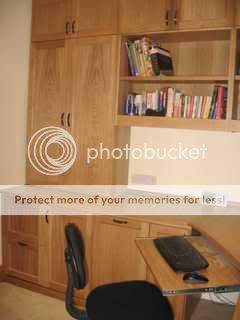

The design came from discussions with the client on how to make best use of a corner of their 'family room' in order to make space for her to work during the day and for the kids to do their homework in the evenings. My normal method is to do rough sketches on site with the client and then do a proper perspective sketch back at home which I can email to them for approval. Old fashioned pencil & paper I'm afraid, I just can't seem to get up to speed on SketchUp!

The carcasses for the cabinets were made from oak-veneered MDF with a 40mm wide oak face-frame on the front. The framed and panelled oak doors sit on the front of the frames on standard concealed hinges.

The only tricky bit was the work-surface. The 'L' shape was made from three pieces of veneered MDF joined with 2 long mitres at 22.5 degrees. I cut the mitres roughly with a jigsaw and trimmed them up with a router and straight edge. The joints were biscuited for alignment and pulled up with worktop connectors mounted on temporary blocks glued and screwed to the underneath of the work surface. Absolute precision is essential with a procedure like this - the veneer is so thin on commercially available boards that the glue up has to be perfect. There is no possibility of sanding out any step in the joint. Next time I do a job like this I will make up my own boards with a thicker veneer - it will also give me the opportunity to match the grain pattern on the mitres.

And that's about it really.

Thanks for looking

Dan