mailee

Established Member

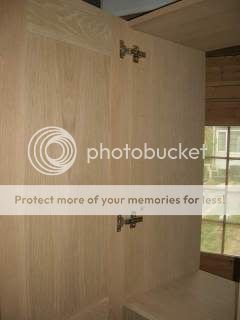

Just about finished building the computer desk. I need to add the back to it and apply the finish. Here are a couple of pictures of the finished item.

I found the Blum hinges really good although I did hit a slight problem with them. I found that the hinge jig I have is slightly out for the Blum hinges. It is only a matter of 2mm but I had to make a new jig to fit them in the right spot. Anyway it worked out right in the end.

I found the Blum hinges really good although I did hit a slight problem with them. I found that the hinge jig I have is slightly out for the Blum hinges. It is only a matter of 2mm but I had to make a new jig to fit them in the right spot. Anyway it worked out right in the end.