woodbloke

Established Member

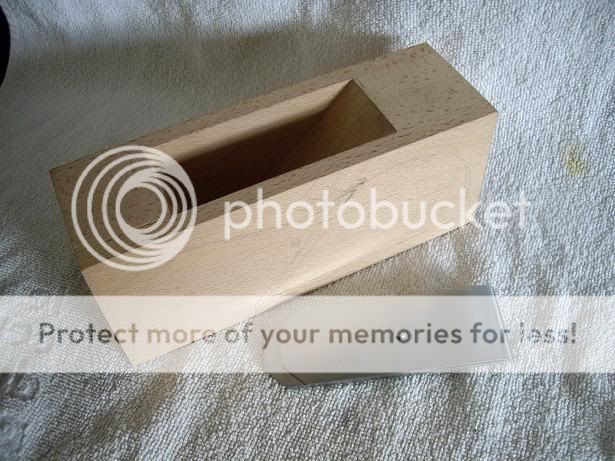

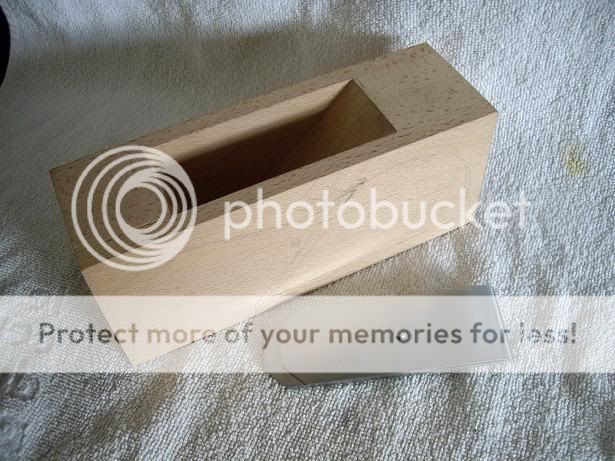

Newt (Pete) came round yesterday for a brew and a Garabaldi. He had with him a plane that he's making and I've put up some WIP pics. Pete's made a superb job of making the cutter and CB and I think the finished plane will be a 'good un' :lol: Pete will be along later to let you know what he's done - Rob