Hi just picked up on your topic and have some comments to make. Firstly I think the comment about the amount of wasted concrete in the pipe (you will also have to dispose of this as they won’t take it away) is very valid. I calculate for a 150mm pipe 60m long it’s about 1 cubic metre!!

I think also a concrete pump will be very expensive plus it will deliver it so quickly that unless you have got half a dozen experienced navvies you won’t be able to cope.

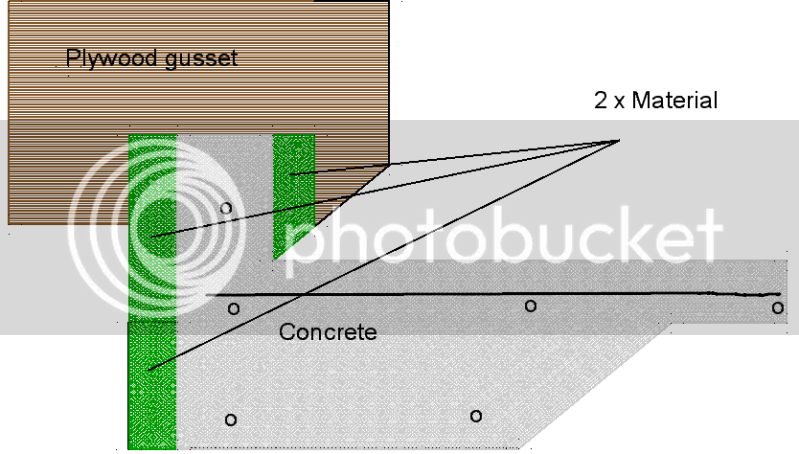

As others have commented I think you need to raise the slab above surrounding ground level and I think this is good advice. I think you need to make your slab so that the main frame of the building sits on the slab and the cladding just overhangs the slab. This way any water run off from the cladding will fall harmlessly to the ground rather than running horizontally beneath the frame sole plate.

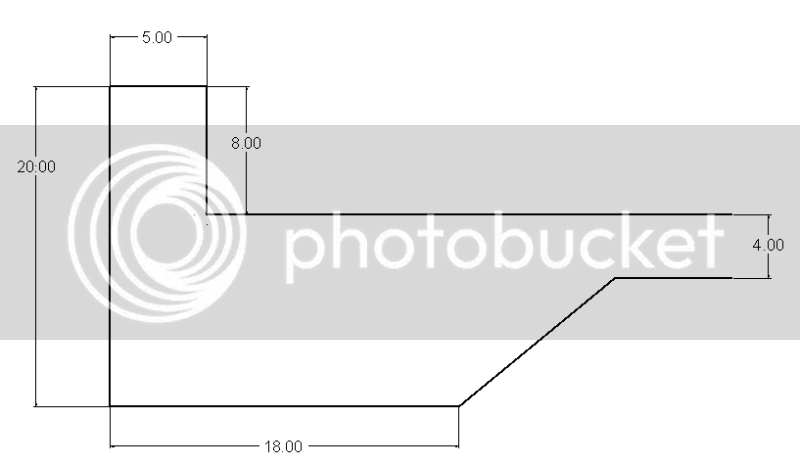

I would suggest a thickening around the edge of the slab so the slab would stand 150mm above the ground, the edge thickness would be 300mm with the main centre area 100mm depth and some light reinforcing mesh. The concrete volume for this would be about 4.5 cubic metres which is about the same as a 150mm slab all over

You would of course need a bit of edge shuttering but this would apply to any concrete slab.

The area in the middle would need to have any organic soil removed and then built up to the required level perhaps using the sand from the ring beam although it would have to be compacted with a plate compactor.

The link to Coppard is a good one. This type of mixer will mix on site to your speed – a 6 cu metre readymix truck is no good because they will want to offload it in half an hour. A little 4wd skip loading dumper would be ideal or if the gradient is impossible a tracked one. As Coppard are in Sussex you should be able to find similar in your area.

Good Luck

Sketchup dwg attached hope it displays