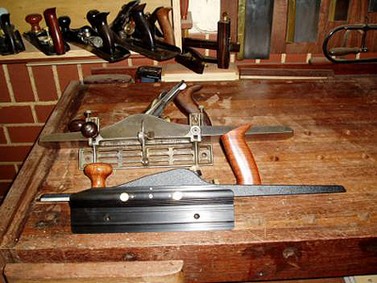

siggy_7

Full time tool collector, part time woodworker

Although I've been on this forum for a few years, I think this is my first visit to the hand tool section so please be gentle with me

I am not normally a hand tool woodworker, but I have need in the very near future (i.e. this week) to glue up some 40mm sapele for use as a kitchen worktop. I'm not happy with the accuracy of the edge I can get with my normal power tool methods, and I have concluded that using a bench plane is probably the way to go to get a true surface for gluing. Given we are talking about 40mm thick hardwood up to 600mm wide, I don't think the usual technique of making the edges slightly curved to get some "spring" is a very good idea, so I reckon dead straight is the way to go.

Now you know the task I would like to tackle, I think that a No.7 jointer plane is the way to go. Given my relatively limited use of hand tools, budgetary wise I imagine the sensible thing to do would be to pick up a used old record plane rather than splash out a quite considerable sum on the Quansheng I was eyeing up, which doesn't seem like a good investment for a tool I'm not likely to use very often. The dilema I have however is that a) I don't really know what I'm doing to fix any flaws in an older plane, and b) I don't have much time to do so either. I presume that for my particular task, the sole flatness is of particular importance on something as hefty as a jointer plane to get a true edge? I would imagine that for someone who doesn't know what he's doing that flattening the sole of a 22" bench plane is going to be a challenging and time consuming affair.

Even assuming I am able to obtain a decent plane, is my idea of being able to get the results I'm looking for with very little practice a sensible one or should I look for other options to accomplish my task? Although not much involved with hand tools, I do have a set of Ultex diamond sharpening plates up to 1200 grit and a Veritas honing guide which I use for my chisels and existing plane irons (block and smoothing). I've no doubt that my results would leave much to be desired for most of you, but I am able to get what I consider to be an acceptably sharp edge with these methods so I think I can keep the plane sharp enough for the task I'm hoping to accomplish.

As you can probably tell, I feel quite out of my depth here and any advice is welcome.

I am not normally a hand tool woodworker, but I have need in the very near future (i.e. this week) to glue up some 40mm sapele for use as a kitchen worktop. I'm not happy with the accuracy of the edge I can get with my normal power tool methods, and I have concluded that using a bench plane is probably the way to go to get a true surface for gluing. Given we are talking about 40mm thick hardwood up to 600mm wide, I don't think the usual technique of making the edges slightly curved to get some "spring" is a very good idea, so I reckon dead straight is the way to go.

Now you know the task I would like to tackle, I think that a No.7 jointer plane is the way to go. Given my relatively limited use of hand tools, budgetary wise I imagine the sensible thing to do would be to pick up a used old record plane rather than splash out a quite considerable sum on the Quansheng I was eyeing up, which doesn't seem like a good investment for a tool I'm not likely to use very often. The dilema I have however is that a) I don't really know what I'm doing to fix any flaws in an older plane, and b) I don't have much time to do so either. I presume that for my particular task, the sole flatness is of particular importance on something as hefty as a jointer plane to get a true edge? I would imagine that for someone who doesn't know what he's doing that flattening the sole of a 22" bench plane is going to be a challenging and time consuming affair.

Even assuming I am able to obtain a decent plane, is my idea of being able to get the results I'm looking for with very little practice a sensible one or should I look for other options to accomplish my task? Although not much involved with hand tools, I do have a set of Ultex diamond sharpening plates up to 1200 grit and a Veritas honing guide which I use for my chisels and existing plane irons (block and smoothing). I've no doubt that my results would leave much to be desired for most of you, but I am able to get what I consider to be an acceptably sharp edge with these methods so I think I can keep the plane sharp enough for the task I'm hoping to accomplish.

As you can probably tell, I feel quite out of my depth here and any advice is welcome.