Hi all

I've been a bit quiet on here lately, but have kept up with my reading if not posting.

Tonight I finally got round to taking the camera into my workshop so I could post a tour of it. Still some things I'd like to do but this is what it's currently like.

In a previous life it was a single car garage - it measures 16ft by 8ft, so could be bigger... :wink:

Here's the view from the entrance - double doors in case anything big ever needs to come in again.

Along the right hand wall are my woodrat and p/t underneath on a mobile base:

Then comes the tablesaw, also on a mobile base so I can swing it round for longer crosscuts. It's the SIP 10" but I've taken out one of the wings and put a router table in which holds one of B&Q's bargain priced Tritons

Next is the workbench - a cobbled together affair from two benches that were being 'retired' from one of the woodwork classrooms. It needs some work on the top and one day I hope to replace it with something that's a bit more presentable:

Above the bench is my latest tool cupboard knocked up from mdf offcuts with pocket hole joinery. Amongst other things it houses the plane kindly donated by Mignal...

Then comes the very underused scrollsaw (also purchased from school as part of the same upgrade that made the solid beech benches obsolete). One of the reasons it's not getting any use is because I've tidied up so well I can't find any of the blades! My dust extractor is in the corner and is plumbed in with blast gates going to the various machines.

On the back wall are not one but two drill presses - both donated by kindly folk...and of course the computer (well we are in the 21st century!) so I can browse the forum, ogle the offerings from Axminster, Classic Hand Tools, etc and use listen again...

On the left hand wall, starting at the back, is my lathe - a second hand record cl2. I need to sort out the wall space above to provide storage for my woodturning tools - it still houses the remanants of my handtools when the bench was here before the lathe arrived.

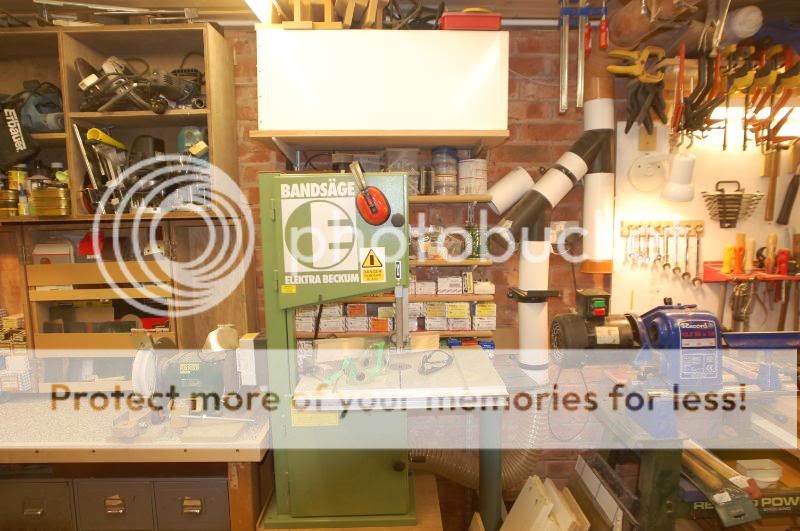

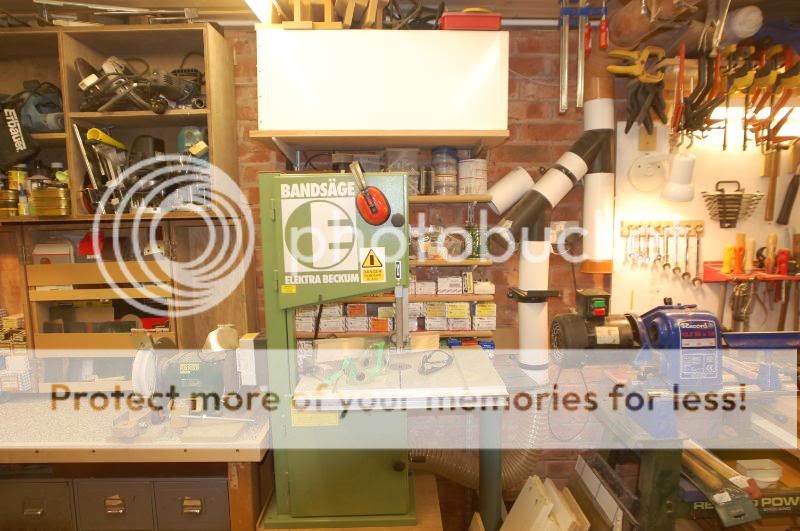

Then the bandsaw, an Elektra Beckum 315, also second hand, on a homemade mobile base. Above it is my air filter.

Then a narrow workbench, made from the base of the second school bench I acquired. I'm not too sure what to use it for so it's got my grinder on it at the moment, with my attempt to make a sharpening jig to grind a fingernail profile partly visible...

Finally, at the front of the workshop on the left is my metal lathe, a Myford ML10, which I haven't really got to grips with yet. Also storage for small offcuts underneath and a corner to lean clamps in while I wait for inspiration to strike and fashion a better way to store them...

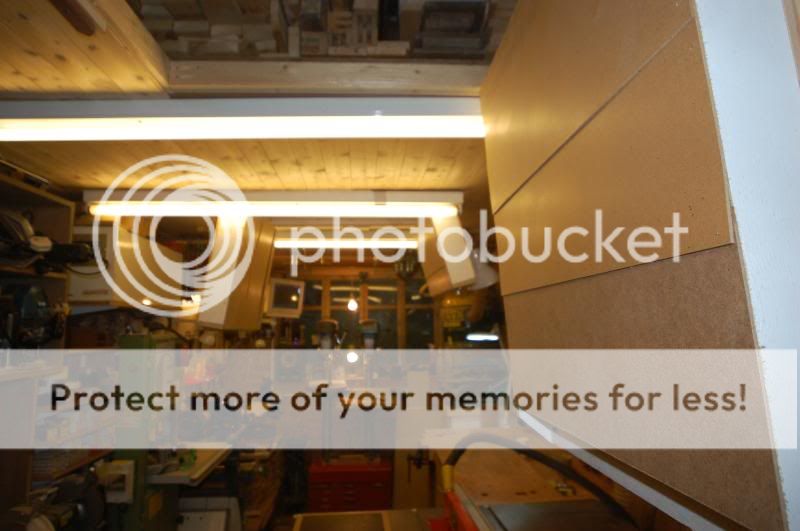

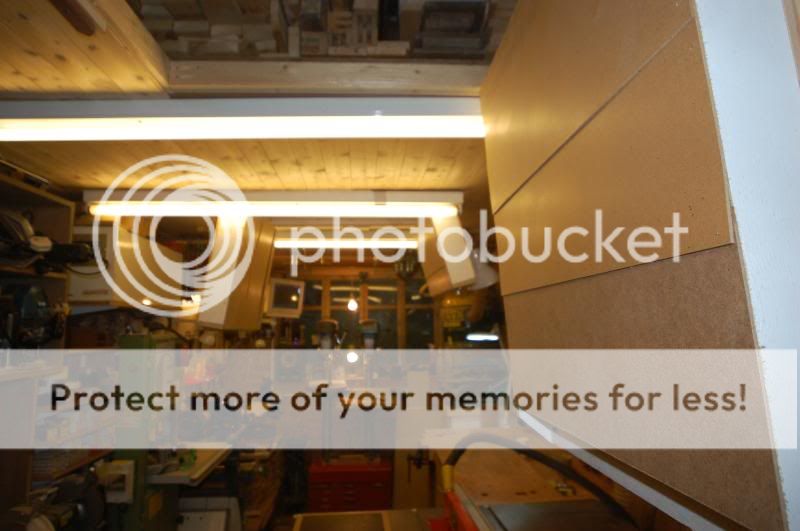

The roof space isn't wasted - there are two openings in the clad and insulated ceiling giving good access to the loft space, which is of course completely full...

A last shot of the whole thing...

End of tour - hope you liked it... now to actually getting down to using it for it's really for :roll:

I've been a bit quiet on here lately, but have kept up with my reading if not posting.

Tonight I finally got round to taking the camera into my workshop so I could post a tour of it. Still some things I'd like to do but this is what it's currently like.

In a previous life it was a single car garage - it measures 16ft by 8ft, so could be bigger... :wink:

Here's the view from the entrance - double doors in case anything big ever needs to come in again.

Along the right hand wall are my woodrat and p/t underneath on a mobile base:

Then comes the tablesaw, also on a mobile base so I can swing it round for longer crosscuts. It's the SIP 10" but I've taken out one of the wings and put a router table in which holds one of B&Q's bargain priced Tritons

Next is the workbench - a cobbled together affair from two benches that were being 'retired' from one of the woodwork classrooms. It needs some work on the top and one day I hope to replace it with something that's a bit more presentable:

Above the bench is my latest tool cupboard knocked up from mdf offcuts with pocket hole joinery. Amongst other things it houses the plane kindly donated by Mignal...

Then comes the very underused scrollsaw (also purchased from school as part of the same upgrade that made the solid beech benches obsolete). One of the reasons it's not getting any use is because I've tidied up so well I can't find any of the blades! My dust extractor is in the corner and is plumbed in with blast gates going to the various machines.

On the back wall are not one but two drill presses - both donated by kindly folk...and of course the computer (well we are in the 21st century!) so I can browse the forum, ogle the offerings from Axminster, Classic Hand Tools, etc and use listen again...

On the left hand wall, starting at the back, is my lathe - a second hand record cl2. I need to sort out the wall space above to provide storage for my woodturning tools - it still houses the remanants of my handtools when the bench was here before the lathe arrived.

Then the bandsaw, an Elektra Beckum 315, also second hand, on a homemade mobile base. Above it is my air filter.

Then a narrow workbench, made from the base of the second school bench I acquired. I'm not too sure what to use it for so it's got my grinder on it at the moment, with my attempt to make a sharpening jig to grind a fingernail profile partly visible...

Finally, at the front of the workshop on the left is my metal lathe, a Myford ML10, which I haven't really got to grips with yet. Also storage for small offcuts underneath and a corner to lean clamps in while I wait for inspiration to strike and fashion a better way to store them...

The roof space isn't wasted - there are two openings in the clad and insulated ceiling giving good access to the loft space, which is of course completely full...

A last shot of the whole thing...

End of tour - hope you liked it... now to actually getting down to using it for it's really for :roll: