Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

PerranOak":2b3b3tvr said:Cheers wizer but it's the 45deg I can't get fof the shooting board in the first place. It's a Catch 22. I need a 45deg "thing" to make the 45deg thing that I need to make 45deg things!

Large piece of paper, ruler and a pair of compasses:

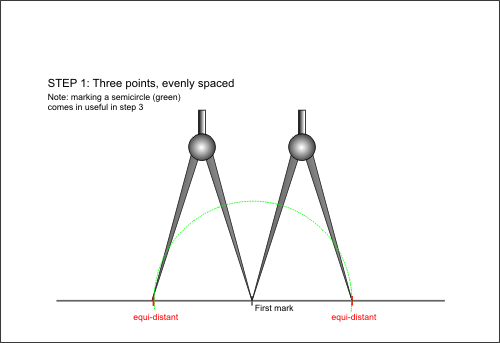

Step 1: Draw a line near one edge of the paper and roughly parallel to it. mark a point near the middle. Set your compasses to, say around 3 inch gap. Put the point on the mark, and make two new marks on the line, either side (these are equidistant from your first point). This is what you should have:

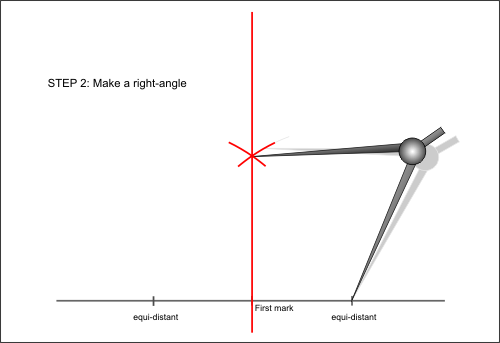

Step 2: Make a right-angle: Open the compasses slightly more. put the point on one of the new marks and make an arc roughly over your original point in the centre of the line. Repeat on the other side, being careful not to change the compass setting. Join the point where the arcs cross with your original point for a near-perfect right angle:

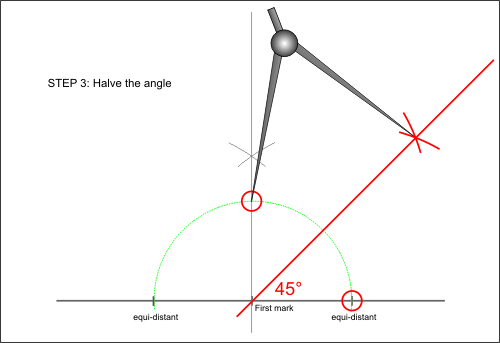

Step 3: your semicircle from step one gives you a crossing point on your new right angled line. Use this, with one of your original marks (in the red circles below), as centres. make two new arcs with the compasses: where they cross is the bisector of the angle (this works for any angle, obviously).

The straight line running through this and your very first point is at 45 degrees to your original line.

This method is as old as the hills and as accurate as your ability to draw straight lines and keep the compasses' pencil sharp, and will be better the bigger-scale you draw it out to. A drawing-pin and string works too, if you only have a pencil and no compass!

Once you have an accurate 45 degree angle (and you can draw this straight onto MDF, obviously) you have the basis for your shooting board...

Once again, apologies if I'm telling granny about egg-sucking, but judging from what my teenage children tell me, formal geometry is no longer taught in schools: if you're young, there's no reason why you should ever have done this before, and there's no shame in not knowing how!