custard

Established Member

phil.p":kiwvgroc said:"I like lots of different gauges so I don't get them mixed up"

All the more reason to use only one or maybe two, I'd have thought. :?

I don't know if you're serious or not. If you're serious you're wrong.

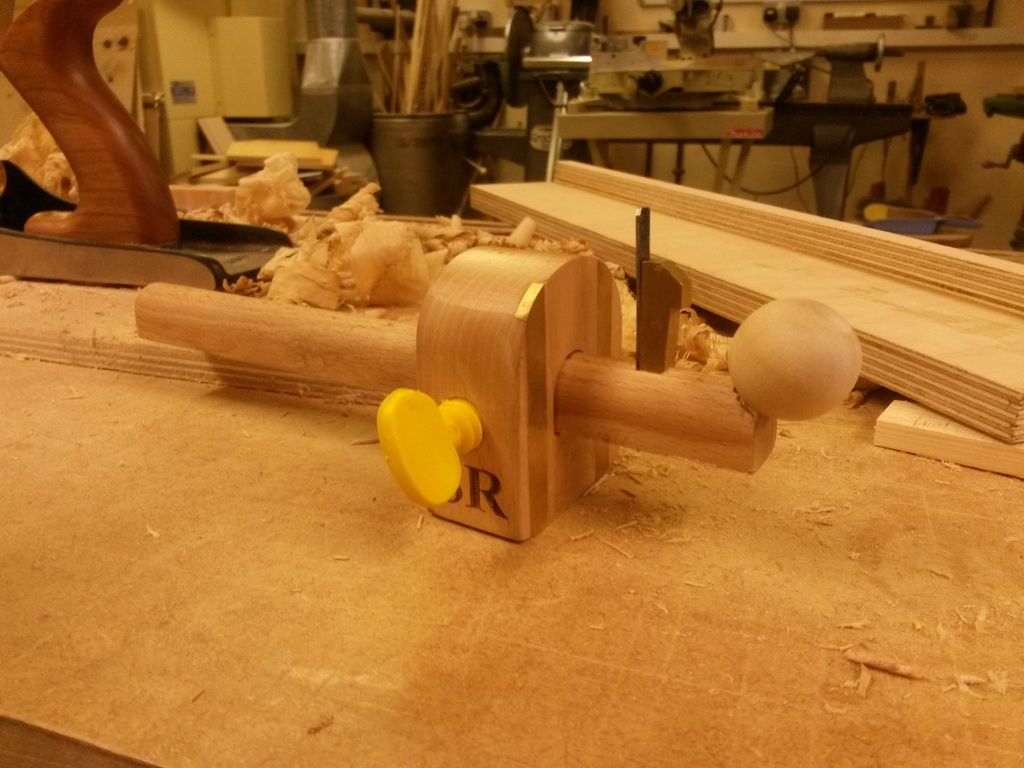

It's almost impossible to re-set a gauge to precisely the same setting once it's been altered, you can get it nearly correct and that's maybe good enough for making a birdhouse or something similar. But for top quality furniture you need better, so if at any point during a job you need to remake a component or check a measurement then the original gauge is in the same position it was for the original gauge line. Hence you need lots of gauges. Ideally they're different styles or have different coloured tape around the handles so you can positively identify the gauge with the joint on your rod.

It's one of the areas newcomers to woodwork go wrong. They spend their money on the glitzy stuff. You don't actually need many tools, what you need is plenty of superbly functioning lay out, marking and measuring instruments, plus masses of clamps!