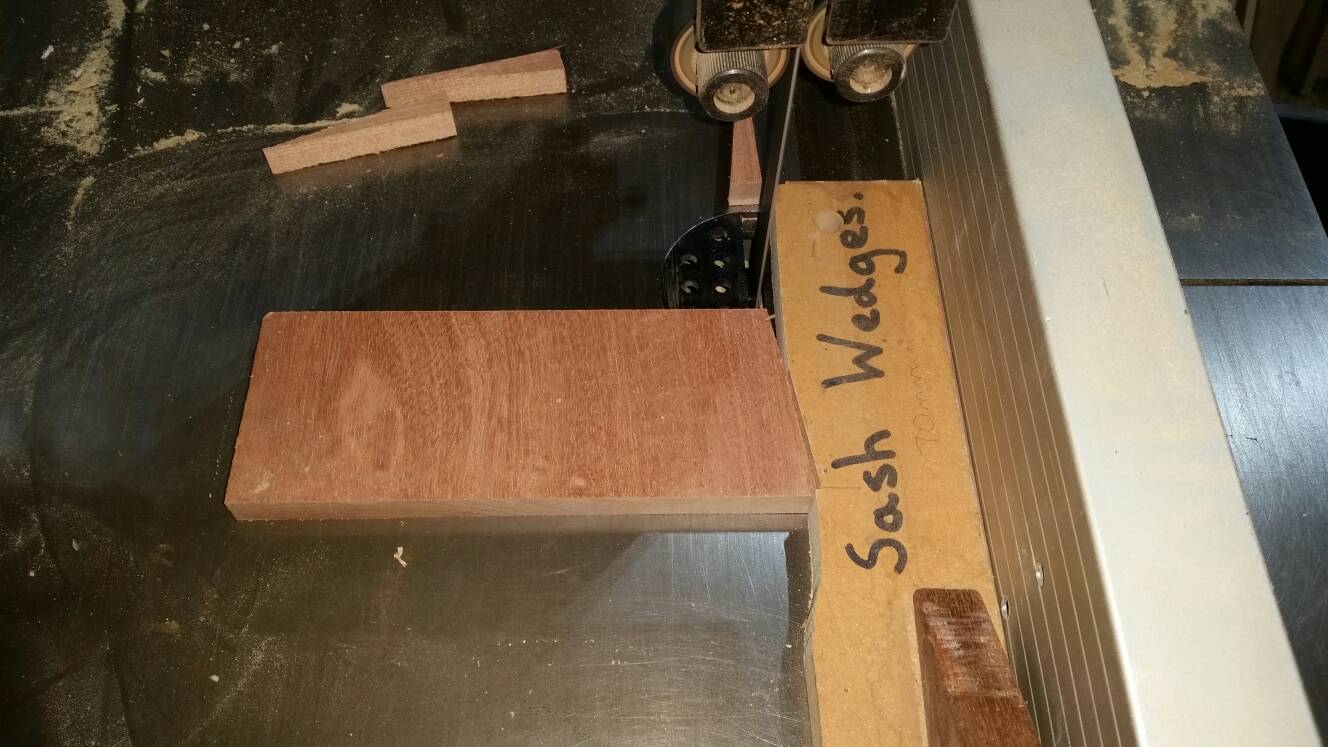

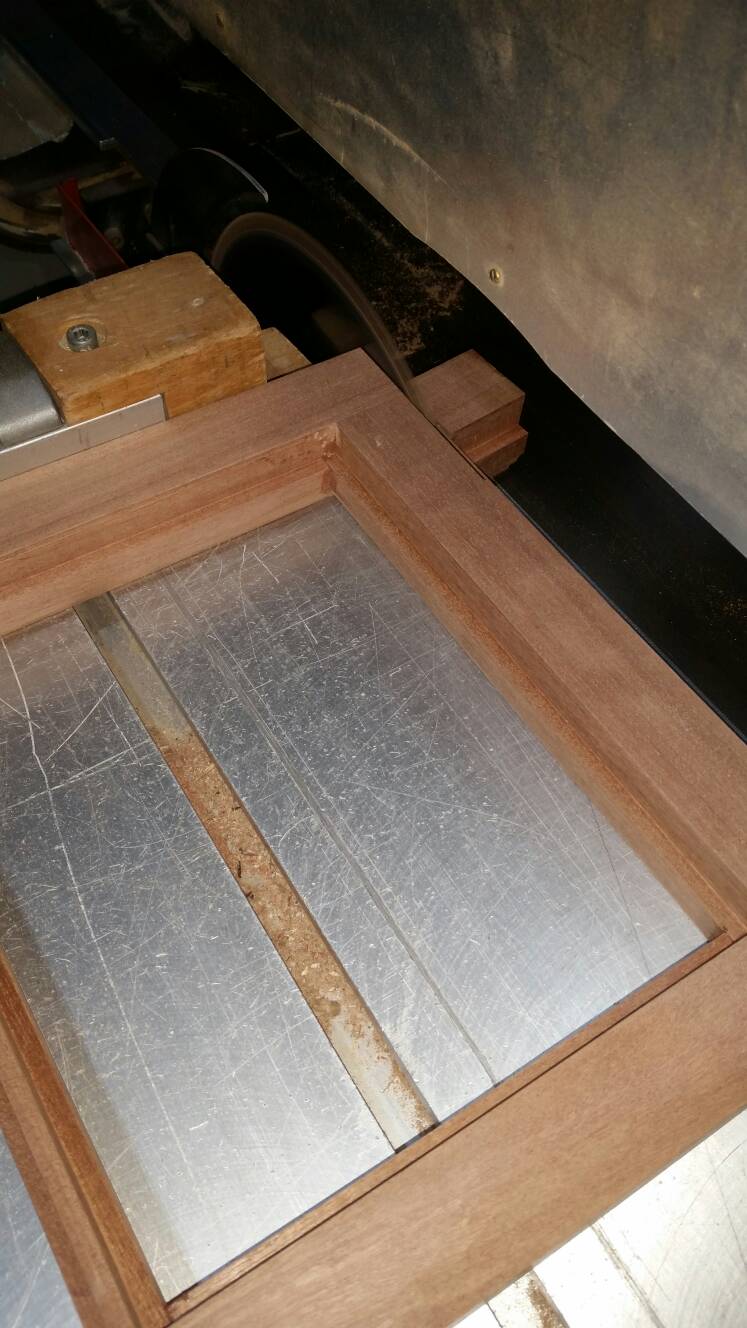

I've always enjoyed the fitting of sashes for some reason, as sad as that might sound. Even though I could have probably saved a few quid by machining the joints, I still on occasion think it's worth taking longer and then proper enjoying it.meccarroll":2ix6p2xy said:ColeyS1":2ix6p2xy said:Hi Mark. I would normally do things slightly differently, the most obvious difference would be using a scriber on the tenoner for the sashs. This would also mean the tenoning and scribing would be done before the rebate and mould. I was hoping to show that someone who perhaps didn't fancy doing all the machining, could just buy in all the sections required.meccarroll":2ix6p2xy said:Hi looking at your workshop equipment and trollies for material movement I'd say you do this sort of work for a living. You have already said that the sequence of machining is

not how you would make a window in practice but show it this way so a novice might find the sequence easier to follow.

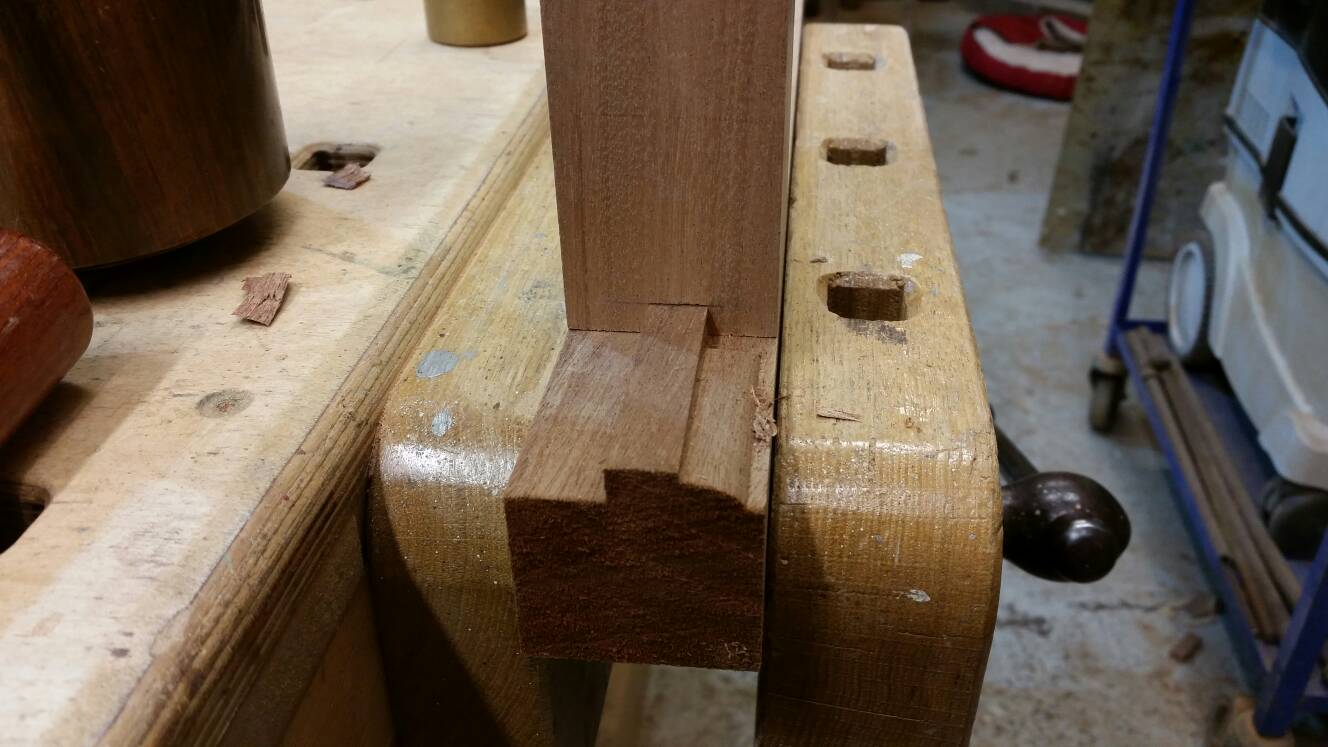

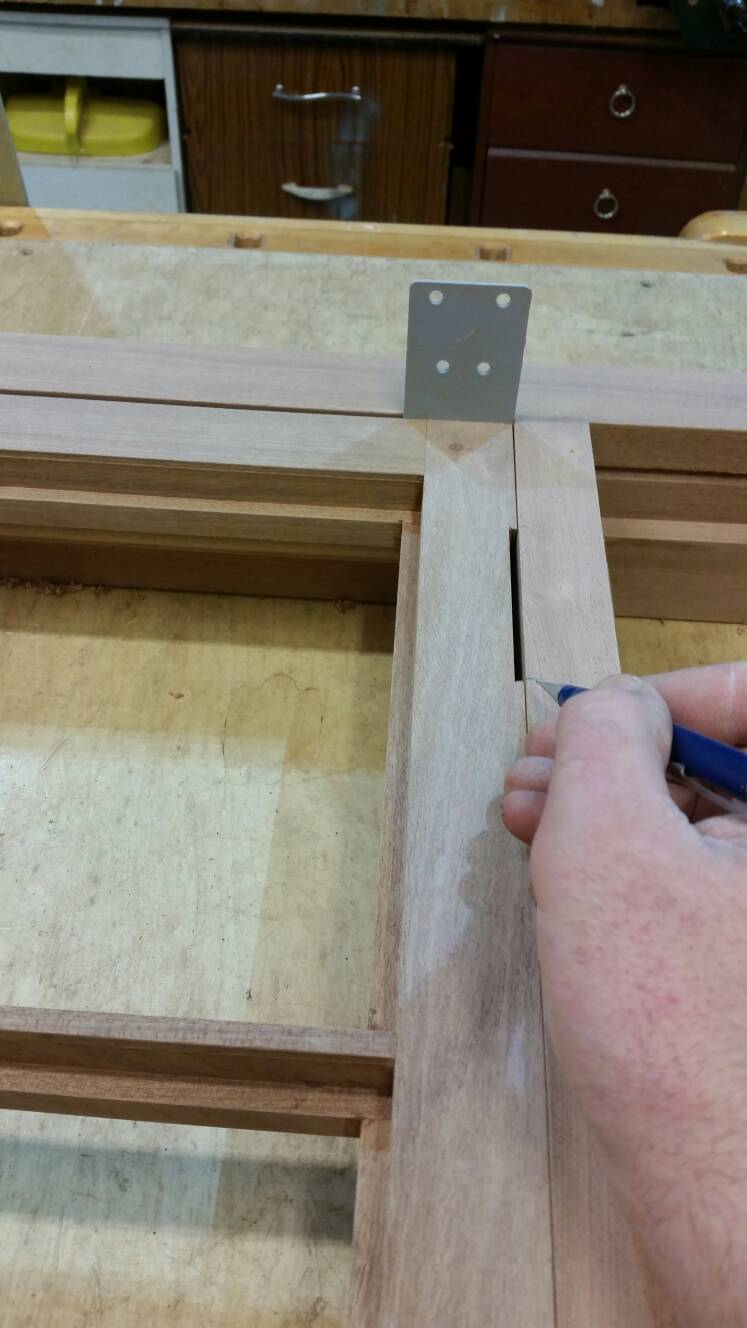

The only technique that puzzles me, with regard to the frame, is why you put a shoulder on the side of the mullions at the M+T joint (a shoulder either side of the tenon and in line with it?).

Mark

I'm glad you raised the point about the notches on the frame tenons. For years I just made the tenons the same width, with no real problems. Depending on how warm/roasting the central heating was set, varied how much a gap you'd see when the tenons decided to shrink. Rather than see a hole, it seemed better to in effect scribe them over aswell. More work, but I think slightly better than a straight through joint.

Theres also the thought that if water did somehow find its way ontop of the head, the notch should help it from dripping inside.

Same width tenon, perfectly acceptable. Notched/scribed one, perhaps a tad better.

Thanks for taking the time to read this. I'm relieved it's not all coming out as complete gibberish :lol:

Coley

Thank you for the reply Coley. It's very nice that you have taken the time to construct a window in a way that makes it easier for a newcomer to follow rather than show how you would actually make a window when doing it to make money. I think this will be very helpful to a first time window maker or anyone contemplating making a window for the first time.

Mark =D>

Coley