Some forum members have asked for the photos , so here we go :mrgreen:

.

.

Good so far

2.2KW 3 HP Siemens motor

.

.

.

with speed readout and adjustable start and stop ramps

Nice size hand wheel , bored through for knock out bar also tapped 1/2 UNC for a vacuum adapter

.

The drive belt pulley cover has a micro switch to stop the lathe when the door is open

.

.

The chassis number and CE approval

.

Nice tight indexing facility

.

With 1/2 a turn lock and unlock lever

.

The tail stock has a measure fitted as standard that is useful for drilling / boring

and a good size hand wheel

.

The head / tail stock and tool rest fixing are the best I have ever seen , the joints are huge , I have place a £2 coin so you can see the scale of things

.

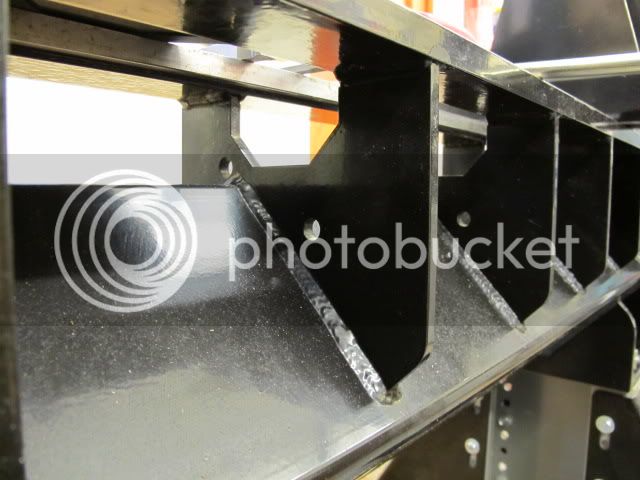

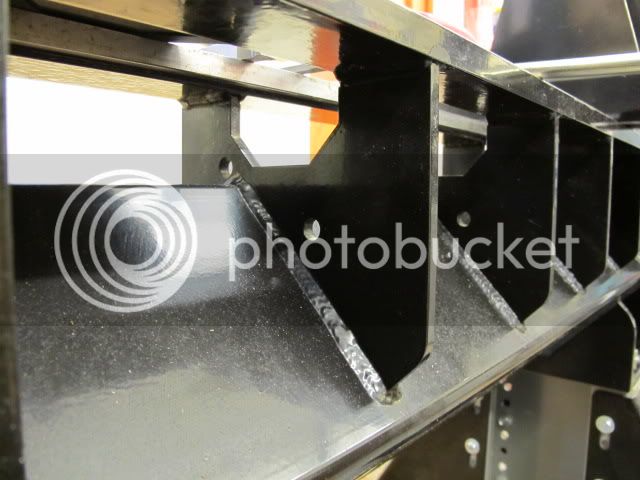

The thickness of the lathe construction is amazing

.

all components are laser cut for accuracy and the welding is spot on

.

.

Even the legs are made from thick steel

.

and each leg is height adjustable

The main chassis is hollow and can be filled to increase the weight :shock: , it already weighs 300 KGS :shock:

.

The head stock locking leaver is big

.

The head stock can be moved and fixed to any position on the lathe bed

.

.

Now on to my niggles :?

The main body end caps are held in place with double sided sticky backed magnetic tape

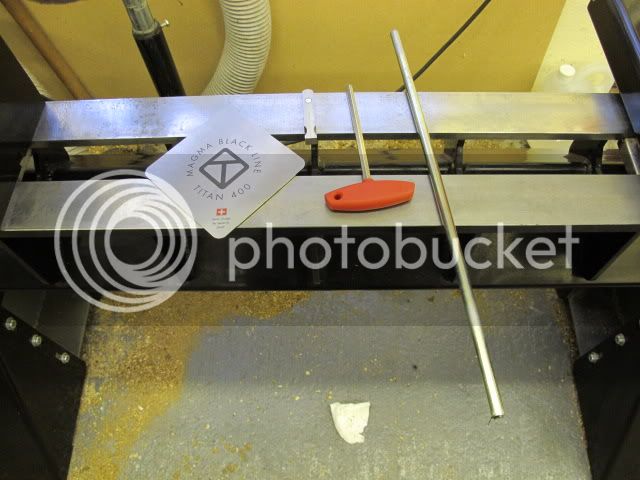

The knock out bar is just a bit of rod , no handle and I think it could do with being a bigger diameter ( more weight )

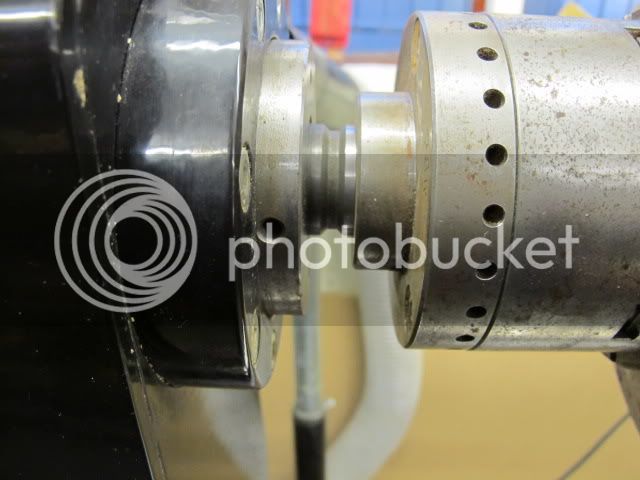

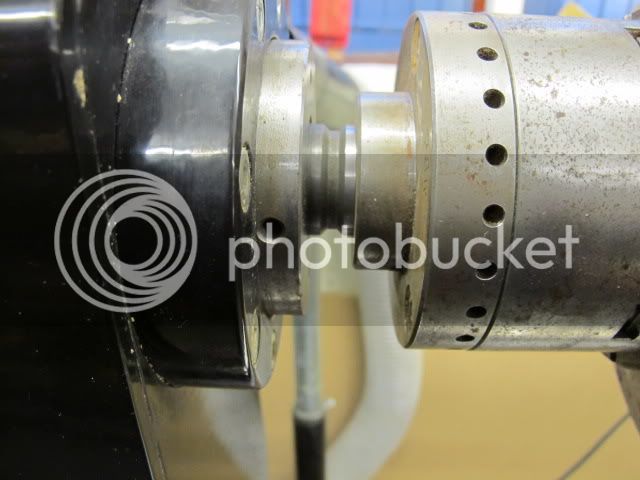

Most of my chucks are Axminster super precision , and are M33 x 1.5 , as it the Titan 400 , however the spindle on the Titon is longer and the chucks bottom out before reaching the spindle flange :?

I spoke to Classic Hand Tools and they are aware of the long spindle and suggested I contact Axminster to see if they could overcome the problem , Axminsters reply was " sorry cant help " as we dont do small runs on our machines ? , so to date I am still looking for a engineering firm to make me 2 spacers

.

When purchasing a lathe they normally come with the following :-

Drive center

revolving center

face plate

sometimes a chuck

a screw chuck

Instruction book etc

What does the Titan come with ?, nothing :shock: , however I did manage to get a One-Way tail stock center included in the deal , but it was hard work

sorry it does come with a 300mm tool rest , but I had to buy this lot to have full use of the lathe facility's , at an extra cost of £500 notes , as they are 40mm dia I dont think anyone else makes them that big ? maybe VB but I cant remember !

also comes with several a4 bits of paper in a 1p ring binder sleeve ( The instruction manual )

What would I do to improve things :-

1, Have a proper instruction book in a nice leather binder ( will get one to shut me up )

2, Do away with the sticky tape and have proper fixings for the end plates

3, Include the drive center / revolving center and face plate and a decent knock out bar

4 Have a laser etched stainless steel plate made with the Titan logo rather that a cheap plastic sticker , would you get a plastic sticker on a Rolls Royce ???

So what do I think of the lathe ??????????????????????

I am in LOVE with a machine

its fantastic I love it ,Love it ,Love it

I can't see me changing in the near future as I think I am as near to a perfect lathe as I can now get

And boy do I know as I have had a few lathes in the past :roll: :roll:

:roll: :roll:

Blurb from the Magma web site

TITAN 400

Specification:

- Swing over bed 400 mm - Distance between centres 800mm - Smooth running - Perfect torsional rigidity - Efficient ejection of wood shavings - Swivelling and sliding head stock - Morsetaper MT2 hardened - Spindle thread M33/DIN800 hardened - Inside thread 1/2“ at back for vaccum connection - Hollow spindle diameter 60 mm - extremely flat toolrest support - for 30 mm and 40 mm stem - Tailstock with 200 mm quill travel, MT3 - Extendable bed - 48 position indexing - Weight approx. 380 kgs - Motor 2,2 kW, 50 Hz - Inverter 230 V - variable speed up to 3000 rpm - Powder coated - Handwheel - 2 step Poly-V-Pulley drive - Forward / Reverse drive - Sturdy A-frame height-adjustable legs

and a link to the web site if needed

http://www.magma-tools.de/Director/idKe ... lack+Line/

Hope you enjoy the photos and review

:ho2 :ho2 :ho2

.

.

Good so far

2.2KW 3 HP Siemens motor

.

.

.

with speed readout and adjustable start and stop ramps

Nice size hand wheel , bored through for knock out bar also tapped 1/2 UNC for a vacuum adapter

.

The drive belt pulley cover has a micro switch to stop the lathe when the door is open

.

.

The chassis number and CE approval

.

Nice tight indexing facility

.

With 1/2 a turn lock and unlock lever

.

The tail stock has a measure fitted as standard that is useful for drilling / boring

and a good size hand wheel

.

The head / tail stock and tool rest fixing are the best I have ever seen , the joints are huge , I have place a £2 coin so you can see the scale of things

.

The thickness of the lathe construction is amazing

.

all components are laser cut for accuracy and the welding is spot on

.

.

Even the legs are made from thick steel

.

and each leg is height adjustable

The main chassis is hollow and can be filled to increase the weight :shock: , it already weighs 300 KGS :shock:

.

The head stock locking leaver is big

.

The head stock can be moved and fixed to any position on the lathe bed

.

.

Now on to my niggles :?

The main body end caps are held in place with double sided sticky backed magnetic tape

The knock out bar is just a bit of rod , no handle and I think it could do with being a bigger diameter ( more weight )

Most of my chucks are Axminster super precision , and are M33 x 1.5 , as it the Titan 400 , however the spindle on the Titon is longer and the chucks bottom out before reaching the spindle flange :?

I spoke to Classic Hand Tools and they are aware of the long spindle and suggested I contact Axminster to see if they could overcome the problem , Axminsters reply was " sorry cant help " as we dont do small runs on our machines ? , so to date I am still looking for a engineering firm to make me 2 spacers

.

When purchasing a lathe they normally come with the following :-

Drive center

revolving center

face plate

sometimes a chuck

a screw chuck

Instruction book etc

What does the Titan come with ?, nothing :shock: , however I did manage to get a One-Way tail stock center included in the deal , but it was hard work

sorry it does come with a 300mm tool rest , but I had to buy this lot to have full use of the lathe facility's , at an extra cost of £500 notes , as they are 40mm dia I dont think anyone else makes them that big ? maybe VB but I cant remember !

also comes with several a4 bits of paper in a 1p ring binder sleeve ( The instruction manual )

What would I do to improve things :-

1, Have a proper instruction book in a nice leather binder ( will get one to shut me up )

2, Do away with the sticky tape and have proper fixings for the end plates

3, Include the drive center / revolving center and face plate and a decent knock out bar

4 Have a laser etched stainless steel plate made with the Titan logo rather that a cheap plastic sticker , would you get a plastic sticker on a Rolls Royce ???

So what do I think of the lathe ??????????????????????

I am in LOVE with a machine

its fantastic I love it ,Love it ,Love it

I can't see me changing in the near future as I think I am as near to a perfect lathe as I can now get

And boy do I know as I have had a few lathes in the past

Blurb from the Magma web site

TITAN 400

Specification:

- Swing over bed 400 mm - Distance between centres 800mm - Smooth running - Perfect torsional rigidity - Efficient ejection of wood shavings - Swivelling and sliding head stock - Morsetaper MT2 hardened - Spindle thread M33/DIN800 hardened - Inside thread 1/2“ at back for vaccum connection - Hollow spindle diameter 60 mm - extremely flat toolrest support - for 30 mm and 40 mm stem - Tailstock with 200 mm quill travel, MT3 - Extendable bed - 48 position indexing - Weight approx. 380 kgs - Motor 2,2 kW, 50 Hz - Inverter 230 V - variable speed up to 3000 rpm - Powder coated - Handwheel - 2 step Poly-V-Pulley drive - Forward / Reverse drive - Sturdy A-frame height-adjustable legs

and a link to the web site if needed

http://www.magma-tools.de/Director/idKe ... lack+Line/

Hope you enjoy the photos and review

:ho2 :ho2 :ho2