So would an LA style handle improve the performance of a Bailey pattern? If not why not?

I did buy a low angle jack, can't recall if LV or LN, but found it a PITA - difficult to adjust with an inadequate Norris adjuster and no tilt lever - had to tap the blade with a little hammer!

The whole point of the Bailey design was to make planing easier, not least making a thin blade work just as well as the older heavy versions, for ease and speed of sharpening. Have to be well made of course; quality went downhill as they fell out of use.

Jacob, the short answer is "yes", but the fuller answer is "not necessary". To qualify the latter statement, it is dependent on how and where you direct the force on a Bailey handle.

This is an article I wrote in 2015 when reviewing the Veritas Custom Planes -

Designing a Plane: Handles and Knobs – or how we really use a plane!

Along with the frog angle, the most important decision lies with the ergonomics of the handle.

Lee Valley offers a choice of two styles of handles, and in different sizes: the “Standard” Veritas upright handle, and the more “Traditional”, forward-leaning Bailey style handle. There are also three different choices of knobs.

Understanding how handle design integrates into and affects the performance of a plane has been a strong interest of mine for some time. It is possible to change the balance of a plane, and the way it performs, through the

force vectors that begin with the handle shape and how it is held.

During the course of my research I became aware that many do not actually push their planes as expected by the design of their handle. For example, experienced uses of Stanley planes often praise the handle for being comfortable and offering much control. This is a forward leaning handle, and is expected to direct the force vector towards the mouth.

However, users of these planes do something else.

How do I know? Because I spent much time watching experienced woodworkers actually using both jointers and smoothers - rather than describing how they are used - watching them on DVD and YouTube video. A few are mentioned below. It was very revealing.

Lee Valley has invested a great deal of research into handle design. Handles have been scales down, tilted forward, and there is one that resembles the Stanley. I discussed this area with Rick Blaiklock, and he gave me permission to reprint his communication:

We invited members of the Ottawa Woodworkers Association in to try handles in different configurations. We looked at the woodworkers themselves (height relative to the bench, hand size, etc.) and had them try different planes and applications and fill out surveys of what they liked or didn’t.

Some interesting things we learned:

- We measured people’s hands in multiple dimensions. The only one that mattered was the width.

- As you’ve discovered, the application (smoothing, jointing, etc.) does suggest if you want to be over top vs pushing from behind.

- The location of your work piece (typically driven by Bench height) does play a factor in this as well. Not a surprise.

- We had a couple of testers with arthritic hands. They both commented they had to push with the heel of their palm, not the top and for that reason they very strongly preferred the Veritas-style handle. In fact they were pushing more than they were gripping the handle.

- Some people, but not all, preferred a larger handle on a larger plane. One tester commented “I like the medium handle on the #4, but it feels too small on the #7). This was a minority group, (15-20%) so not a tiny minority.

- Better too big a handle than too small, but not too big. (and what do you do with a goldilocks-statement like that?)

- People in fact do get used to any handle style after regular use.

- For knobs, it’s purely personal. Some people want the ball, some the mushroom. We could not find a way to tell who would prefer what, across anthropometry, plane model and application.

We settled on two designs of totes and had 5 different sizes of each. We created a test box with the handles and a hand measuring guide and put it in the store and asked people to pick which handle they liked and measure their hand size.

Out of this we narrowed down to 3 sizes of each. We have lots of bell curves charts of standard hand size data and the data we collected.

Rick and I are substantially in agreement with the designs; however my explanation of the reason they may or may not work differs. If I can make some sense to you, it may change the way you choose what you use.

Firstly, a couple of long standing hypotheses:

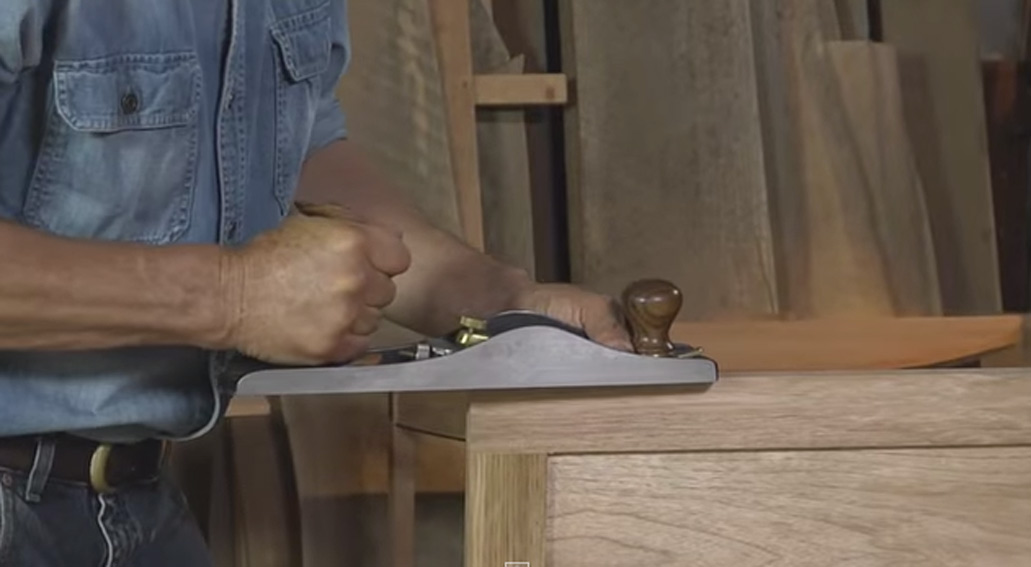

The first hypothesis is that a vertical handle best suits a

high bench and encourages one to push forward. This is shown here with a Veritas BU Jointer …

The second hypothesis is that the forward-leaning Stanley handle encourages one to push down towards the mouth, and that this is more easily facilitated by a

lower bench. This is demonstrated below with a Stanley #7 …

One of the interesting videos I watched was that of

Paul Sellers. In this he demonstrated that a smoother would cut without any downforce.

This was reinforced when Paul pushed the smoother from the base of the handle.

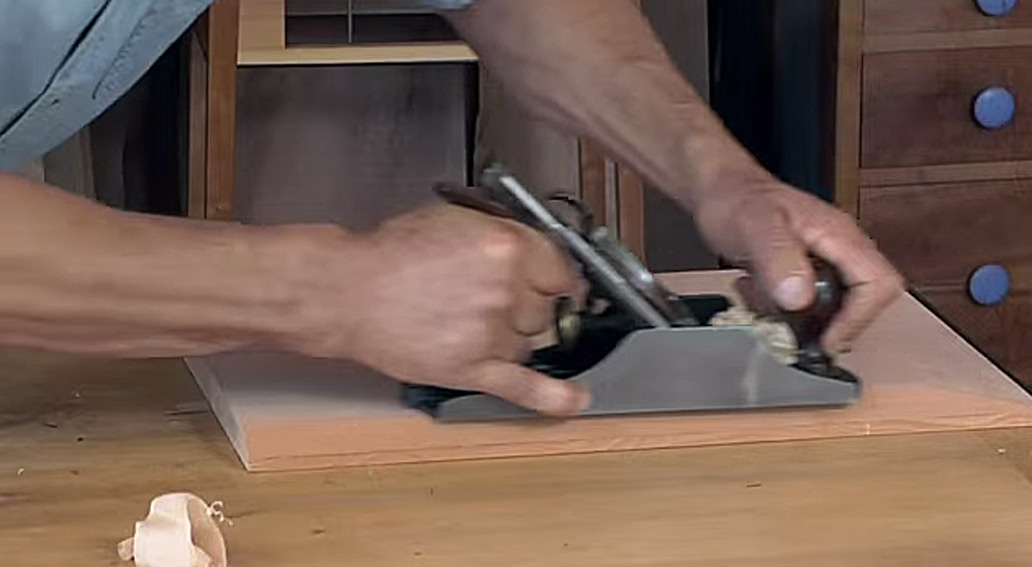

In the next picture we begin to get a clue to what it is all about. Here Paul is pushing a #4. Notice the angle of his forearm – it is parallel to the bench. This means that he is not pushing

down, but pushing on the

horizontal …

This is a process repeated by all experienced woodworkers.

Below is Garrett Hack – notice his horizontal forearm. This is a Lie-Nielsen BU Jack (which has a Bailey-style handle) …

He does exactly the same on a Bedrock #604 ½.

Also note that all the planes so far have Bailey-style handles with a forward lean.

Here is one of Chris Schwarz. He looks like he is leaning down and pushing on the diagonal, however his fist is pointed forwards, as is the direction of his forefinger. Chris is a tall fellow (6’5”) and likes low benches. The forward lean is no doubt related to using a bench that is too low! More about bench height in a little while.

Frank Klausz is a doyen among woodworkers. There are two elements to watch for here. The first is that he drops his arm to push forward (and this is not simply because he has reached the end of the board). The second is that he is not using the knob to generate forward movement – rather, it appears that he is lifting the toe up as the plane reaches the end of the board.

David Charlesworth, teacher extraordinaire! – once again, a strong horizontal push with a Lie-Nielsen LA Jack, plus this time we see the knob being used to place downforce over the toe of the plane … the knob creates the downforce, not the handle.

The pushing action is repeated on a BD Jack. The knob is ignored and the thumb is placed directly on the body in front of the mouth for downforce …

Here is a great shot of

Konrad Sauer repeating the same action of those who came before …

Not one of these individuals is pushing down on the handle, only on the toe.

The next piece of the puzzle begins with a confession. I have had a love-hate relationship with the Veritas handles over the years. I hate their looks, but I love the way they work. And every year or so, I swap them out for something nicer looking, and then swap them back for the original because they just feel better in the hand.

A couple of years ago now I built a new bench, a Roubo. This bench was about 2” lower than my previous one, and I thought that this would be a good reason to add Stanley-style handles to the Veritas BU planes (jointer and jack below) to avoid cocking the wrist when planing.

Bill Rittner makes some beautiful handles and knobs (just like the LN in the picture below)…

Over time, however, I discovered – as good as these handles are (and they are very good indeed) - they are not as comfortable as either of the new Veritas handles ... and so I switched back again! How could this be so?

The key here is body posture. What I found myself doing when planing at a lower bench was to automatically drop my hips and lower my body (thereby “raising” the bench). This posture is a common practice in Karate (where punching power comes from the hip), and other sports where balance creates control creates timing and creates power, such as tennis, squash and skiing … ("bend ze knees!").

Inexperienced woodworkers appear to push down on the handle and lunge forward from the waist or shoulders. This leads to poor balance, poor control and limited power.

Experienced woodworkers, such as Jim Kingshott, describe that there is an optimal position for one’s feet for the push stroke (see his video, “Bench Planes”). Similarly, Jeff Miller (in “The Foundations of Better Woodworking”) demonstrates dropping the planing height as he pushes forward.

<<<<<<<<<<<<<<…………………………………………………………..<<<<<<<<<<<<<<<<

Obviously, by squatting low, the effective height of the bench is being raised. What I discovered I was doing was simply compensating for the lowered bench, dropping down lower and pushing the plane forward … as if I was working at a higher bench and standing more upright. This meant that the “advantage” of a forward leaning Bailey handle was lost.

Here is an illustration. Below is my bench. Notice that the top aligns with the hem of my t-shirt.

Now in the sequence below note that the hem has dropped below the skirt of the bench (about 5”), and it does not move in height as I shift my weight forward. The hips are the source of the forward drive and transfer force into the lowered forearms.

<<<<<<<<<<<<<<< ……………………………………………………<<<<<<<<<<<<<<<<<<

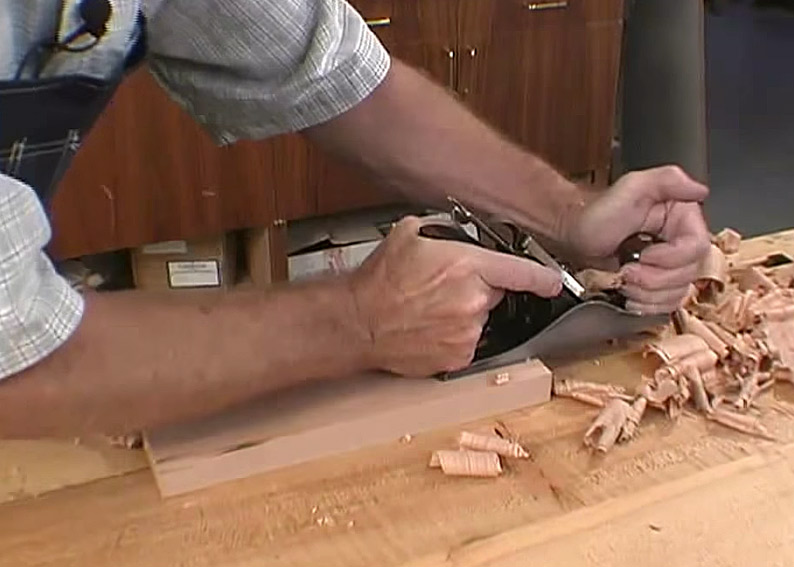

Below is the forearm driving the plane through the

base of the handle …. Now recall the words of Rick Blaiklock:

“We had a couple of testers with arthritic hands. They both commented they had to push with the heel of their palm, not the top and for that reason they very strongly preferred the Veritas-style handle. In fact they were pushing more than they were gripping the handle”.

Bevel Up Jointer …

Custom Jointer …

So where is the effort going with the Stanley handle? Pushing at the base with the heel of the hand leaves a part unsupported.

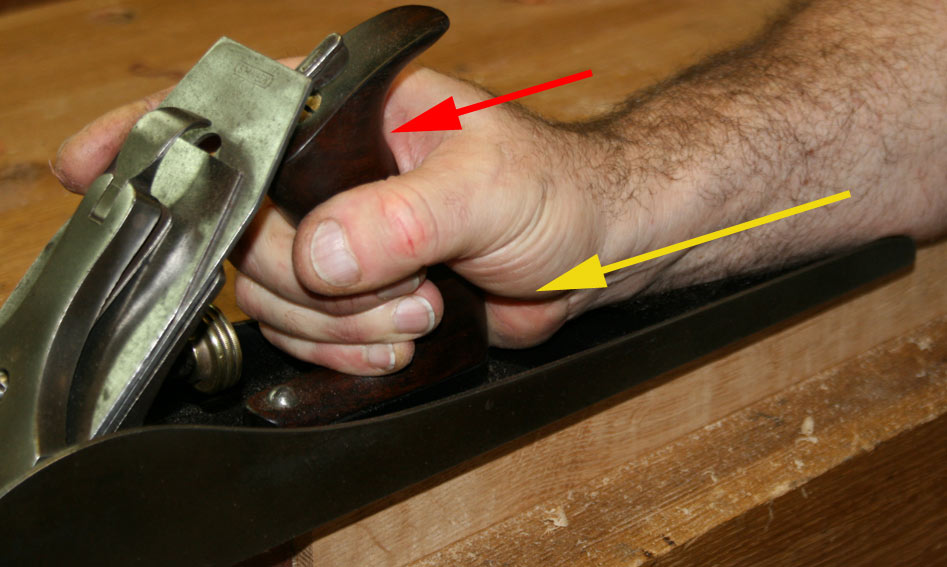

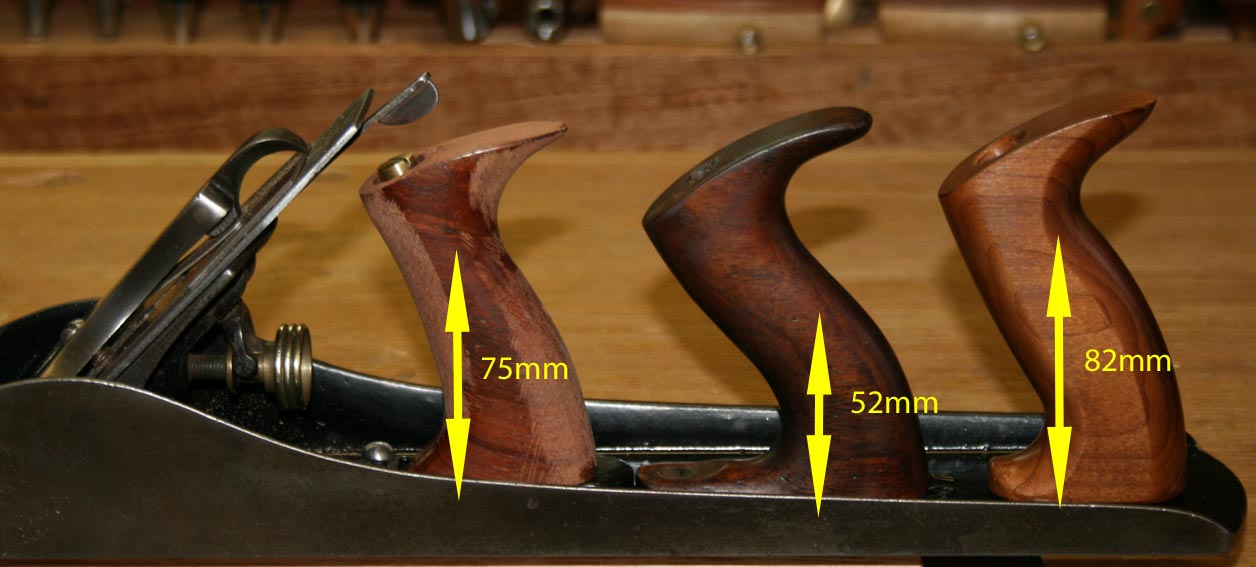

The third part of the puzzle comes from measuring the angle of the handles under discussion. The upper two are the Veritas, and the lower two are the Stanley (left) and LN (right).

What becomes apparent is that they are all within a few degrees of one another in regard to forward lean (somewhere between 68 – 70 degrees) when ignoring the curves. The curve, especially on the Bailey style, creates a distinct upper and lower section to the handle.

It occurred to me that if pushing at the heel creates power, the important handle dimension is not simply about width but about the amount of registration for the heel. I measured the height of the flat where the heel of the hand would rest in a mostly vertical orientation.

It is evident that the Stanley has the least vertical height, and the traditional Veritas has the most. Could this be the reason why arthritic hands enjoy this handle more than any other? Simply, that they have more stable area to push against?

At this point it was necessary to find a way to test out this theory. What I did was build a handle for the Stanley that increased the height of the flat (it’s a bit rough-looking below, but it was cleaned up for the #604 – see later).

How did this feel? In a word, great! Forward drive appeared to require less effort. The Stanley #7 was much less effort and significantly more controllable when pushed.

The question remaining was whether this would have the same effect with a shorter smoother?

Knobs

The question must be asked whether one actually needs a knob on a plane?

If they are not ideal for helping the plane move forward, and primarily for holding the toes flat to the surface, why have one at all - why not simply push on the toe of the body?

Stanley #7 …

Custom #7

Of course, if you prefer to use a downward-leaning handle, then you will need to augment this with a knob that you grasp and push. In this case, the higher the knob, the better.

Veritas offer three knobs:

Wide,

Standard, and

Tall. Lee Valley recommend the Tall knob if you prefer a fisted grasp, the Wide knob is good for pushing downward, and the Standard knob offers something in the middle.

I am convinced that the dominant (but not exclusive) use of a knob on a smoother and a jointer is for downforce. This is how the knobs stack up …

Wide

Standard

Tall

What I like about the wide knob is that it is high enough to tuck fingers under it if the plane requires assistance when pushing on hard wood ..

And it is wide enough as a stable platform when pushing down on wide boards …

This is the case too for the smoother …

Your mileage may vary, but my preference is the Wide knob for both smoother and jointer.

For those with an interest in understanding the ergonomics of plane design, the full article starts here:

https://www.inthewoodshop.com/ToolReviews/VeritasCustomPlanes1.html

Regards from Perth

Derek

January 2015