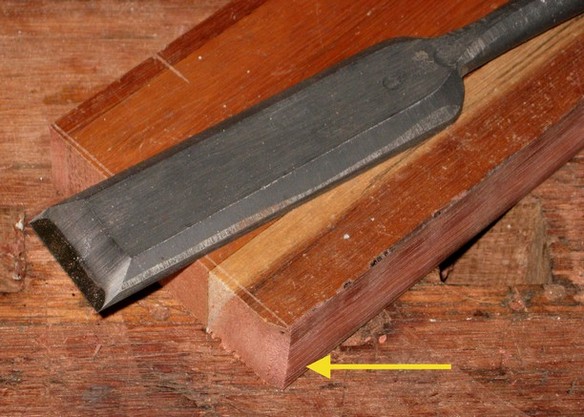

People often say that a low cutting angle is best for end grain. I was trying out my new shooting board with a sort-of-new Veritas low angle jack plane fitted with an A2 blade sharpened with a straight edge at around 27 degrees for an effective pitch around 39. The workpiece is American cherry, a fairly soft easily worked wood.

My observation is that it seemed almost from the first cut like the blade edge had gone ragged. I was getting a decent looking shaving, but the cut surface on the wood had a lot of lines on it running in the cut direction, suggesting that the blade had formed a toothed edge rather than a smooth one.

I'm wondering what to make of this, since the behavior seems worse than with any other plane I've tried...but I thought low effective pitch was supposed to be good for end grain. After I was done I measured one shaving and found it to be 3 thou thick. Too thick?

Could the problem be the A2 steel? I've recently noticed people saying that A2 needs to be sharpened at 30 degrees or more. And in another thread somebody linked to a review of the new LV block plane and complained about the A2.

What should I do to get the best end grain shaving performance?

My observation is that it seemed almost from the first cut like the blade edge had gone ragged. I was getting a decent looking shaving, but the cut surface on the wood had a lot of lines on it running in the cut direction, suggesting that the blade had formed a toothed edge rather than a smooth one.

I'm wondering what to make of this, since the behavior seems worse than with any other plane I've tried...but I thought low effective pitch was supposed to be good for end grain. After I was done I measured one shaving and found it to be 3 thou thick. Too thick?

Could the problem be the A2 steel? I've recently noticed people saying that A2 needs to be sharpened at 30 degrees or more. And in another thread somebody linked to a review of the new LV block plane and complained about the A2.

What should I do to get the best end grain shaving performance?