OPJ

Established Member

As the title suggests, I'm looking to build some form of station for my monster of a sliding compound mitre saw (Bosch 12") with support tables either side and it must be able to move around the workshop. Like the majority of you, I'm sure, space is very much a premium in my workshop too.

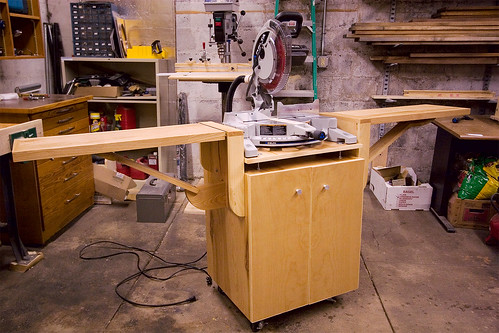

I'm thinking of something along the lines of this:

Click here for more

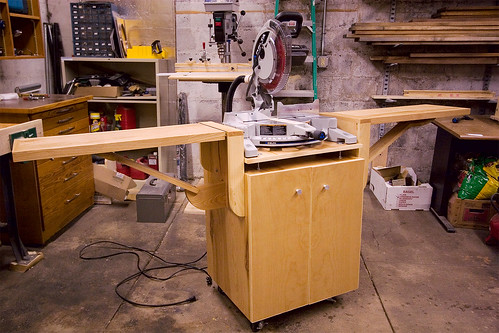

On this next one, I like the adjustable bed he's made to raise/lower the saw's base to finish flush with the two extension tables:

I'm thinking a simple (1/2" ply) but sturdy (rebated edges, etc.) construction for the main cabinet/base will do fine. But... One other thought that has crossed my mind is whether I can perhaps use the right-hand extension (I'm right-handed, therefore, it wouldn't get as much use as the left side) as a kind of router table...! :shock: :wink:

Obviously, I'd have to leave that side of the cabinet 'open', so that the router itself would swing out of the way when I don't need it. The first problem that springs to my mind, though, is that, depending on the router's position, it could foul the gate leg/supporting leg on that side, or vice-versa.

Then, of course, I have to think about dust extraction below the table and how much noise an unenclosed 1,900w router is going to make...?

I reckon the base for my saw (top of cabinet) needs to be roughly 800mm wide, with a depth between 500-600mm. As for the height, the average 'off-the-shelf' stand seems to set the saw at between 800mm and 900mm from the floor.

So. If I'm looking at a table potentially 760mm x 450mm, that's already considerabley larger than my current Bosch RT 60 setup - and, I still have two-thirds the length of the station to run on to.

I'd also appreciate any thoughts on dust extraction/containment for a 12" SCMS. I saw the article in the last issue of British Woodworking (right next to mine! :wink: ) but that was for a fixed model, not a sliding one, where you'd probably have to cut out for the long bars, giving the dust another avenue to escape from. While my vacum works okay, an awful lot of dust manages to cover the wall behind right now.

) but that was for a fixed model, not a sliding one, where you'd probably have to cut out for the long bars, giving the dust another avenue to escape from. While my vacum works okay, an awful lot of dust manages to cover the wall behind right now.

So, what do you guys think of the router table idea, please?

Any other thoughts on what I could include to aid the mitre saw would also be welcome.

Thank you. Much appreciated as always.

I'm thinking of something along the lines of this:

Click here for more

On this next one, I like the adjustable bed he's made to raise/lower the saw's base to finish flush with the two extension tables:

I'm thinking a simple (1/2" ply) but sturdy (rebated edges, etc.) construction for the main cabinet/base will do fine. But... One other thought that has crossed my mind is whether I can perhaps use the right-hand extension (I'm right-handed, therefore, it wouldn't get as much use as the left side) as a kind of router table...! :shock: :wink:

Obviously, I'd have to leave that side of the cabinet 'open', so that the router itself would swing out of the way when I don't need it. The first problem that springs to my mind, though, is that, depending on the router's position, it could foul the gate leg/supporting leg on that side, or vice-versa.

Then, of course, I have to think about dust extraction below the table and how much noise an unenclosed 1,900w router is going to make...?

I reckon the base for my saw (top of cabinet) needs to be roughly 800mm wide, with a depth between 500-600mm. As for the height, the average 'off-the-shelf' stand seems to set the saw at between 800mm and 900mm from the floor.

So. If I'm looking at a table potentially 760mm x 450mm, that's already considerabley larger than my current Bosch RT 60 setup - and, I still have two-thirds the length of the station to run on to.

I'd also appreciate any thoughts on dust extraction/containment for a 12" SCMS. I saw the article in the last issue of British Woodworking (right next to mine! :wink:

So, what do you guys think of the router table idea, please?

Any other thoughts on what I could include to aid the mitre saw would also be welcome.

Thank you. Much appreciated as always.