Finally I managed to get some time to start this at the weekend.

I need to make a strip of curved beading to go around the bottom stair to cover the gap at the edge of the lamianted flooring. The strip is 1/4" thick and 3/4" high. I'll route a profile on it. [The flooring has been down for two years, is settled and < 1/4" is fine. The stair will be fitted with a runner so I only need the beading for the sides not covered by the carpet]

I used a flexi curve around the stair to get the shape, I transfered this to 6mm MDF and cut the inside template using a jig saw and hand tools. This will be used with a profile trimmer to create the inside part of the form. The same template was used to create the matching outside template. Using a 3/8" cutter and 5/8" guide bush I routed the template which at this point is 1/2" larger than the inside one and 1/4" larger than the desired form. Thus with a 1/2" cutter and 1" bush routing around this second template gives my second form part the desired 1/4" larger than the inside/first piece.

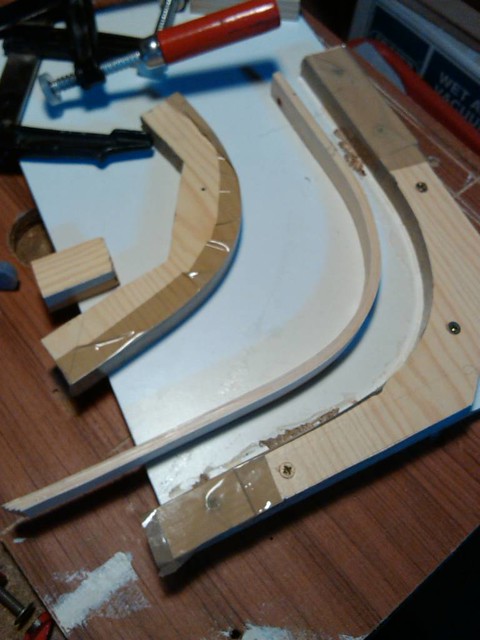

here are the finished templates [the hole was actually a template used to route the grommet holes in my wife's new desk and serves no purpose now]

I made the form pieces from some very old conti type stuff that itself has had two lives. [My brother gave me some shelving about 20 years ago, then maybe 15 years ago I used it as the bottom of a sliding keyboard shelf on a work table for my wife. Recently that table was scrapped as I refurbed her office]

I didn't take any pictures of the form once assembled before I used it I was getting too excited to see if it would all work as I have never done this before. I screwed the outside, fixed, form pieces to a conti board base, covered the bare wood with parcel tape in an attempt to prevent the glue sticking.

Weeks ago I cut some strips, 1.2mm thick, 3/4" wide (forgive the mixed units), five of these would give me the correct thickness, not ten like I said in my original post, I have decided 1/4" is thick enough. I have at least 10 spares anyway so I can make another if I need to.

then glued, using Cascamite as recommended [mixing it and the smell invoked some happy memories of model boat building with my Dad about 35-40 years ago], and clamped up

same thing

and left it overnight.

This morning as I was scooping the cat litter I undid the clamps, pulled off the moveable parts of the form and the workpiece didn't spring off. It was glued to the form but some careful prising with a thin knife eased it away with no damage. Some of the conti facing was stuck to the bottom but it will clean up properly - should have taped it too.

I am pleased with this, my first attempt at curved laminating without a permanent former. No spring back. I'll attempt some more pictures in due course.