mailee

Established Member

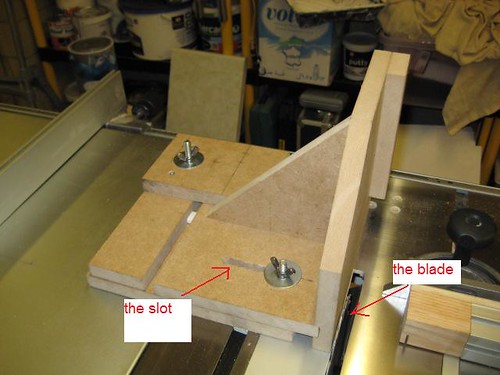

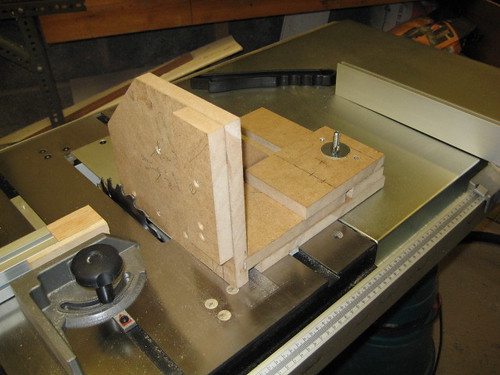

Now I have a powerful table saw I decided to knock up a tennoning jig for it over the weekend. I had seen the Dakota one at Rutlands and thought i could make something along similar lines. Here is my effort:

Seems to do the job well enough and worth a few hours building it.

I did just notice that the Dakota one has been reduced again, ah well, it has kept me amused.

Seems to do the job well enough and worth a few hours building it.

I did just notice that the Dakota one has been reduced again, ah well, it has kept me amused.