JonnyD

Established Member

Just started a Kitchen so I thought I would post some pics for your perusal.

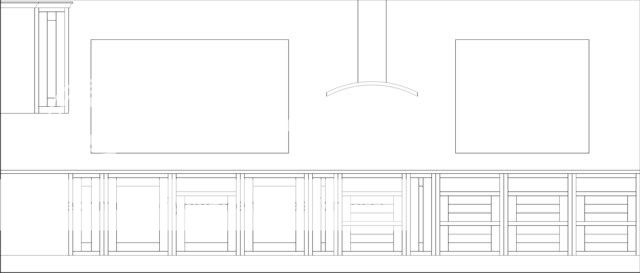

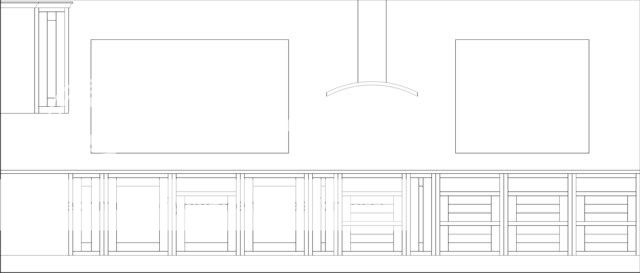

The kitchen is going to have a plain face frame with shaker doors and will be painted white.

Main run of kitchen. the worktops will be corian.

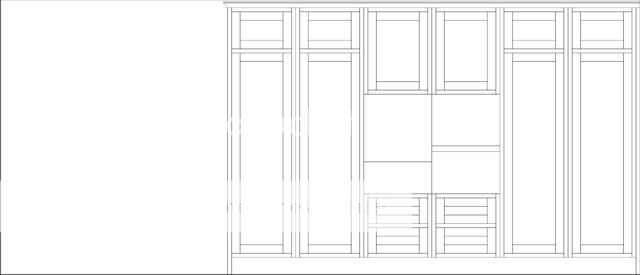

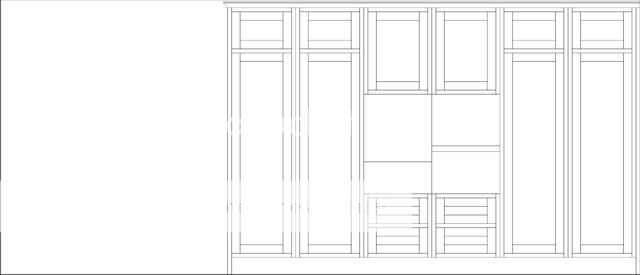

Opposite will be a row of larder units. The right hand side will house the fridge and freezer and In the centre will be an oven and warming drawer on the left hand side and a compact oven and microwave on the right hand side.

Carcases are in a colour called Unica grey although it looks pretty white in the photos.

The Sheets come in at 2800mm X 2070mm and take a bit of handling to get them on the saw.

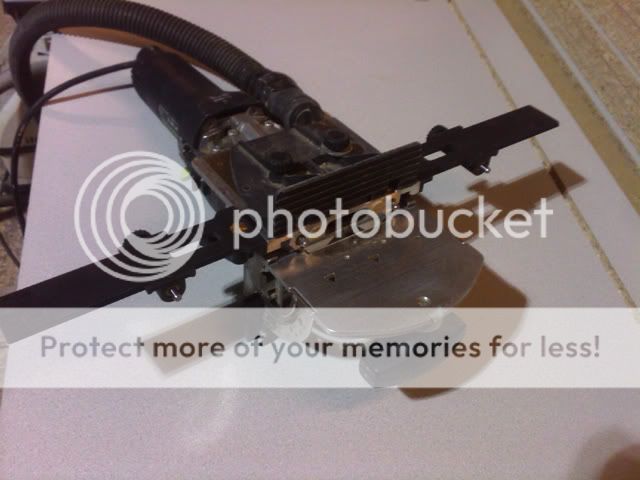

The big sheets are roughly sized and then finally trimmed to size when they are of more manageable sizes.

A secondary fence is used when cutting the panels for the larder units to keep the cuts dead parallel

Stack of components for the base cabinets

Components for the larder units

Had an afternoon on it so far and will keep you updated with progress.

Tomorows jobs should involve making a dent in the 25 cubic ft of Ash for the face frames and doors.

Cheers

Jon

The kitchen is going to have a plain face frame with shaker doors and will be painted white.

Main run of kitchen. the worktops will be corian.

Opposite will be a row of larder units. The right hand side will house the fridge and freezer and In the centre will be an oven and warming drawer on the left hand side and a compact oven and microwave on the right hand side.

Carcases are in a colour called Unica grey although it looks pretty white in the photos.

The Sheets come in at 2800mm X 2070mm and take a bit of handling to get them on the saw.

The big sheets are roughly sized and then finally trimmed to size when they are of more manageable sizes.

A secondary fence is used when cutting the panels for the larder units to keep the cuts dead parallel

Stack of components for the base cabinets

Components for the larder units

Had an afternoon on it so far and will keep you updated with progress.

Tomorows jobs should involve making a dent in the 25 cubic ft of Ash for the face frames and doors.

Cheers

Jon