RobertMP

Established Member

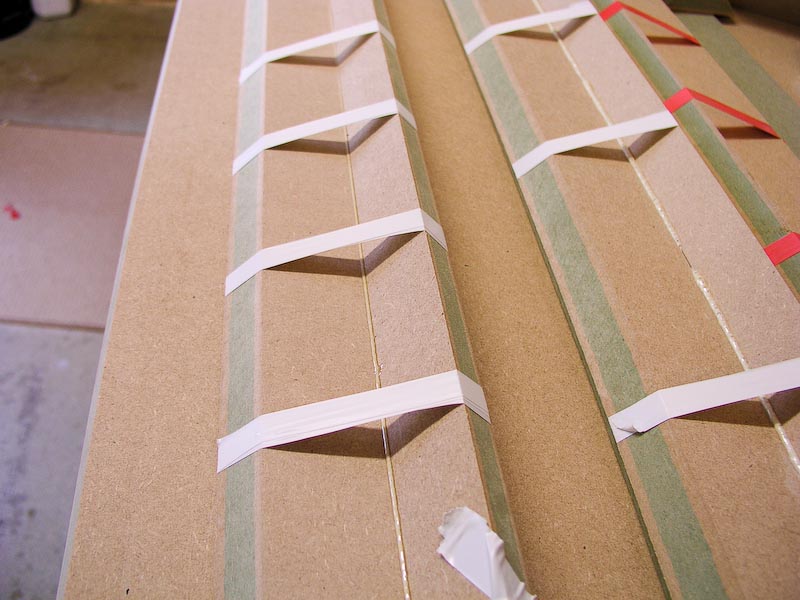

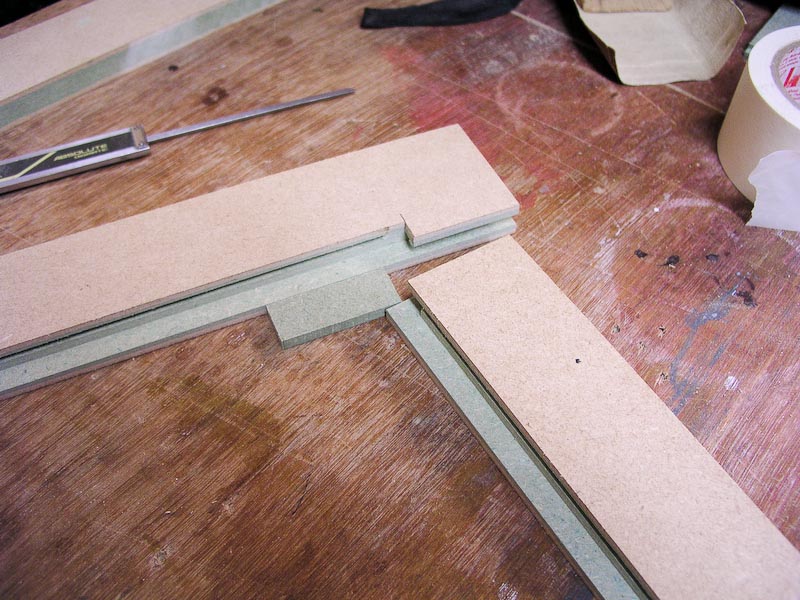

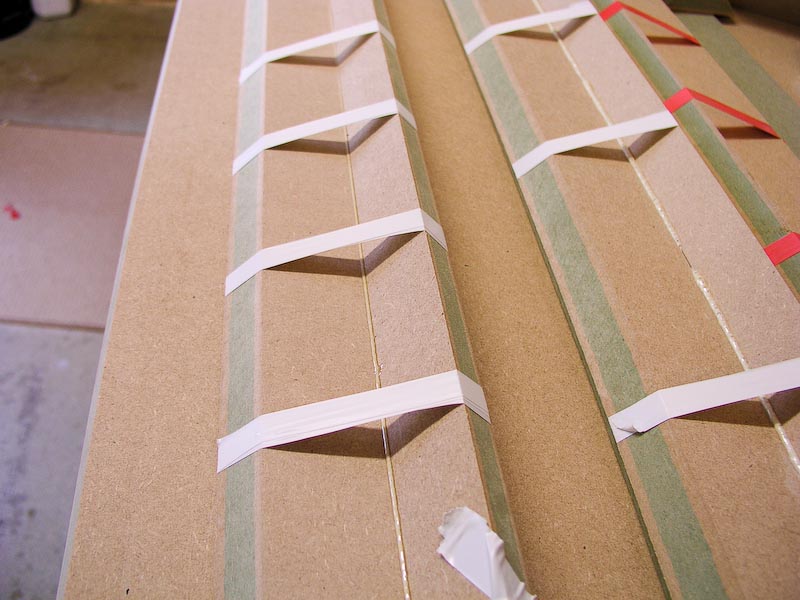

Update on the cornice/ pelmet/ whatever you call it - Now all glued and cut and mitred

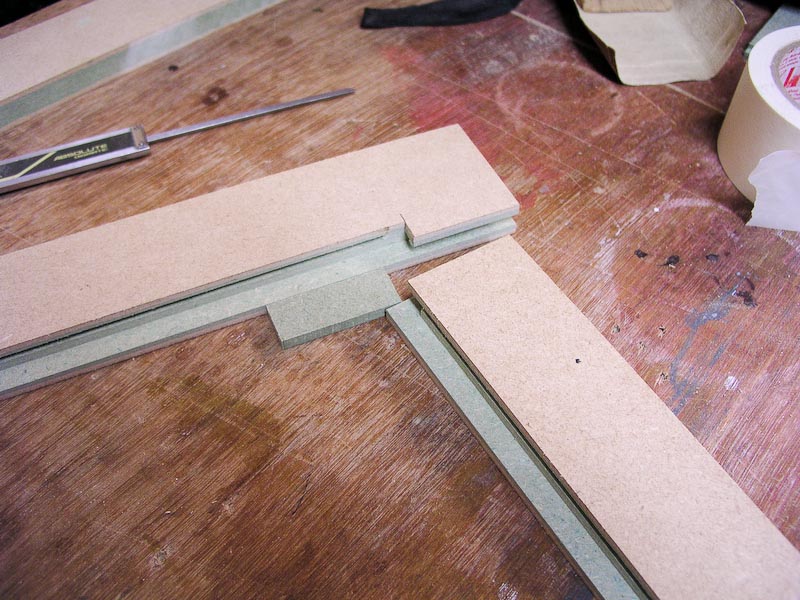

Also made a glass panel door

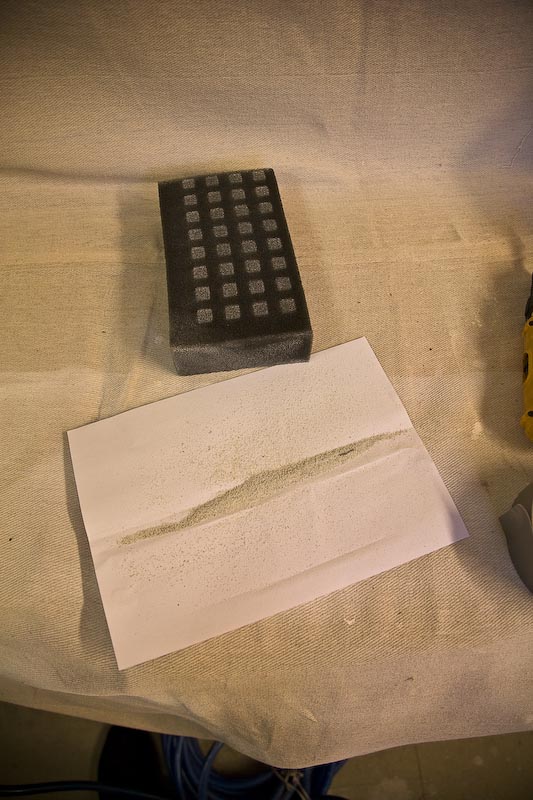

And a beading strip that works quite well. This is a test piece. I've mitred the ends on the ones for the door.

And at last everything is made! I spent the entire day yesterday cleaning and hoovering the entire workshop in order to reduce the chances of dust getting in or on my paintwork.... then I realised i needed some painting jigs and promptly made some more sawdust to clean up!

This is a screwfix roller stand with the roller bar removed and a bit of 1" square tube in its place. I made this when i was practicing a few months ago by spraying the workshop cupboard doors. A bit of steel tube drops over the square tube and welded to it are 3 arms. messy welds using stick on thin tube but it holds . Anyway a big ball bearing sitting on the top of the square tube means it rotates quite nicely with just enough friction to stay put.

. Anyway a big ball bearing sitting on the top of the square tube means it rotates quite nicely with just enough friction to stay put.

the idea is to paint both sides of the panel in one visit - which i could do with the stand as it is - but I'd have to leave the panel on the stand to dry. So I cut some plywood triangles and put a 30 mm screw in each corner. means i can paint and handle 15 panels at a time.

Time to get my spray booth out of the cupboard

The box locates to the frame around my plate extractor

And unfolded. Another frame (not in the picture) with a cloth filter then goes into the front of the extractor so the fan does not get covered in paint.

I paint the back first. I put a couple of bits of cardboard near the fan to baffle the worst of the overspray from the filter so it lasts longer.

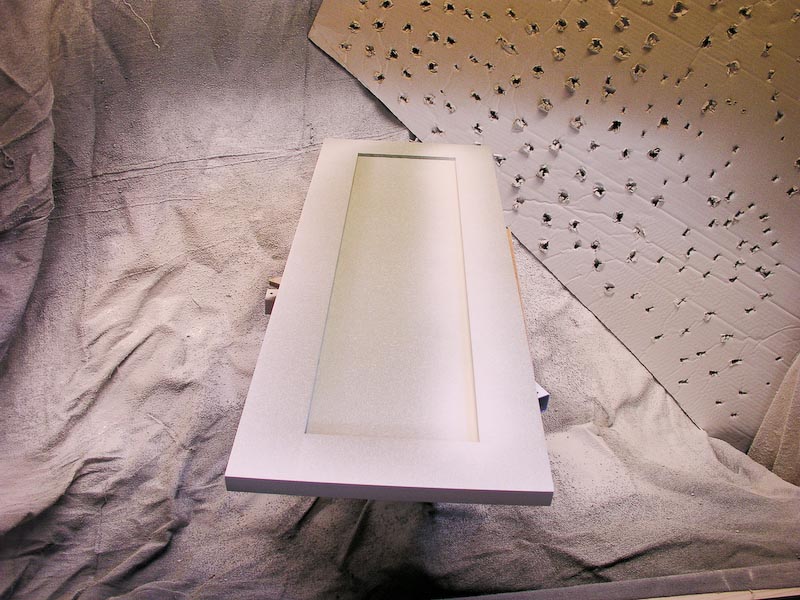

3 small contact points don't notice on the back. Sprayed the edges first including the internal ones.

Then the rest of the face.... now i just have to carry it using the triangle underneath and not touch the wet paint

Stacking space is a problem of course. I have a bit of spur shelving that can be temporarily fitted to the garage door....

And have screwed a few battens at high level so that I can gingerly put some over head height and out of the way. I may have 15 triangles but i don't think I have room for 15 panels :lol:

Oh and you can see my practice grey paint on the workshop cupboard doors (B & Q 50p clearance paint ! )

Also made a glass panel door

And a beading strip that works quite well. This is a test piece. I've mitred the ends on the ones for the door.

And at last everything is made! I spent the entire day yesterday cleaning and hoovering the entire workshop in order to reduce the chances of dust getting in or on my paintwork.... then I realised i needed some painting jigs and promptly made some more sawdust to clean up!

This is a screwfix roller stand with the roller bar removed and a bit of 1" square tube in its place. I made this when i was practicing a few months ago by spraying the workshop cupboard doors. A bit of steel tube drops over the square tube and welded to it are 3 arms. messy welds using stick on thin tube but it holds

the idea is to paint both sides of the panel in one visit - which i could do with the stand as it is - but I'd have to leave the panel on the stand to dry. So I cut some plywood triangles and put a 30 mm screw in each corner. means i can paint and handle 15 panels at a time.

Time to get my spray booth out of the cupboard

The box locates to the frame around my plate extractor

And unfolded. Another frame (not in the picture) with a cloth filter then goes into the front of the extractor so the fan does not get covered in paint.

I paint the back first. I put a couple of bits of cardboard near the fan to baffle the worst of the overspray from the filter so it lasts longer.

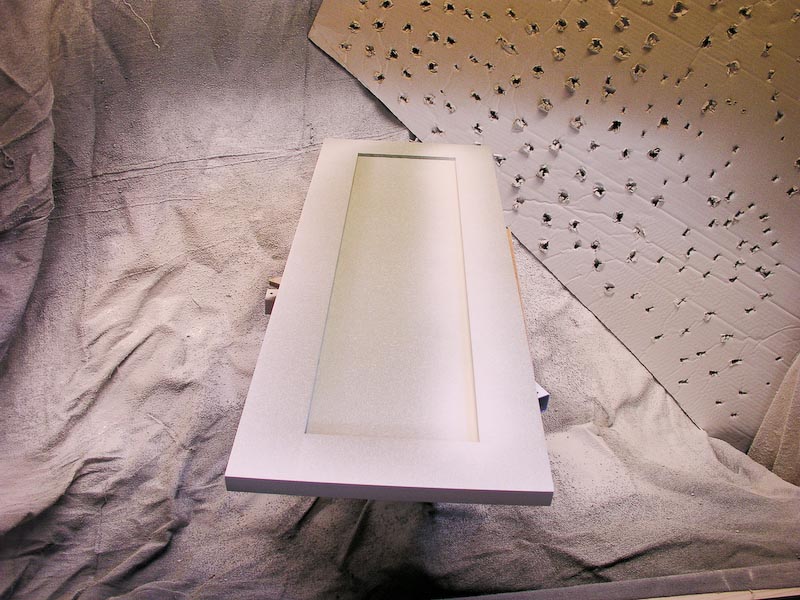

3 small contact points don't notice on the back. Sprayed the edges first including the internal ones.

Then the rest of the face.... now i just have to carry it using the triangle underneath and not touch the wet paint

Stacking space is a problem of course. I have a bit of spur shelving that can be temporarily fitted to the garage door....

And have screwed a few battens at high level so that I can gingerly put some over head height and out of the way. I may have 15 triangles but i don't think I have room for 15 panels :lol:

Oh and you can see my practice grey paint on the workshop cupboard doors (B & Q 50p clearance paint ! )