TrimTheKing

Established Member

Well seeing as Tom is moaning (not like him  ) that we don't get enough WIP threads any more I thought I would kick off this one. We are expecting bambino #2 in about 10 weeks and I made the foolish commitment to making a bedroom suite for her new room (she's being evicted from the nursery) rather than let SWMBO spend stupid money on Mark Wilkinson stuff :shock: :shock:

) that we don't get enough WIP threads any more I thought I would kick off this one. We are expecting bambino #2 in about 10 weeks and I made the foolish commitment to making a bedroom suite for her new room (she's being evicted from the nursery) rather than let SWMBO spend stupid money on Mark Wilkinson stuff :shock: :shock:

Well, we are a single income household now she's a housewife so need to be frugal!!!

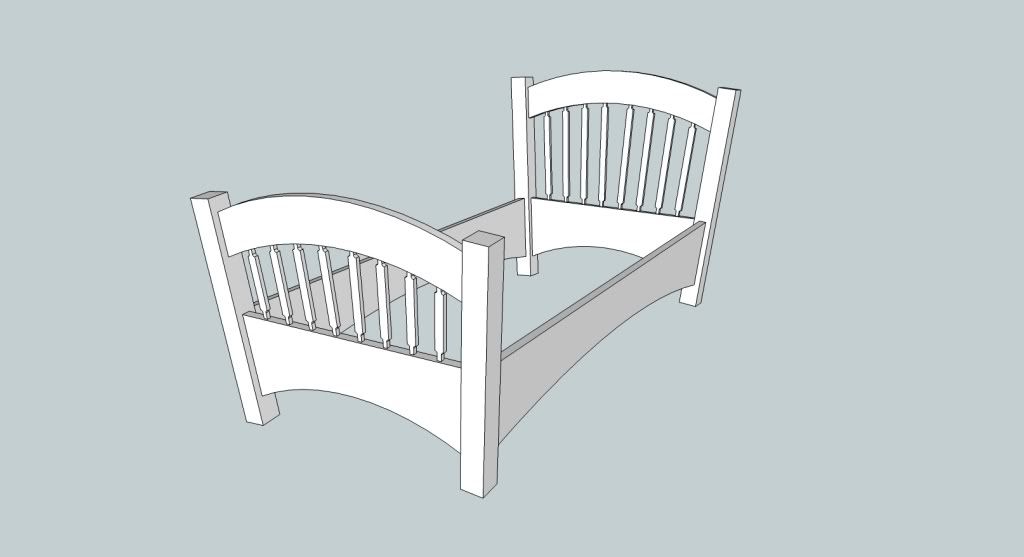

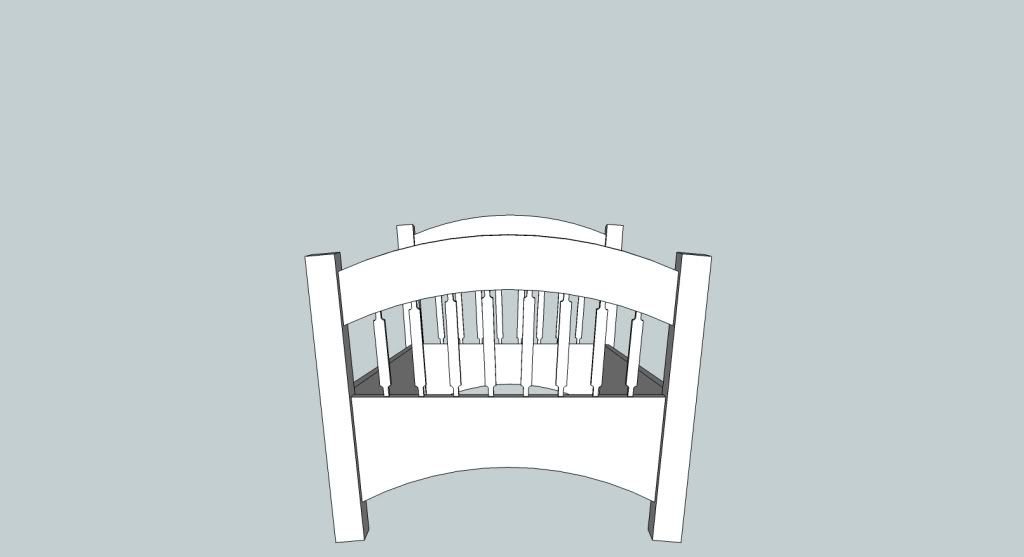

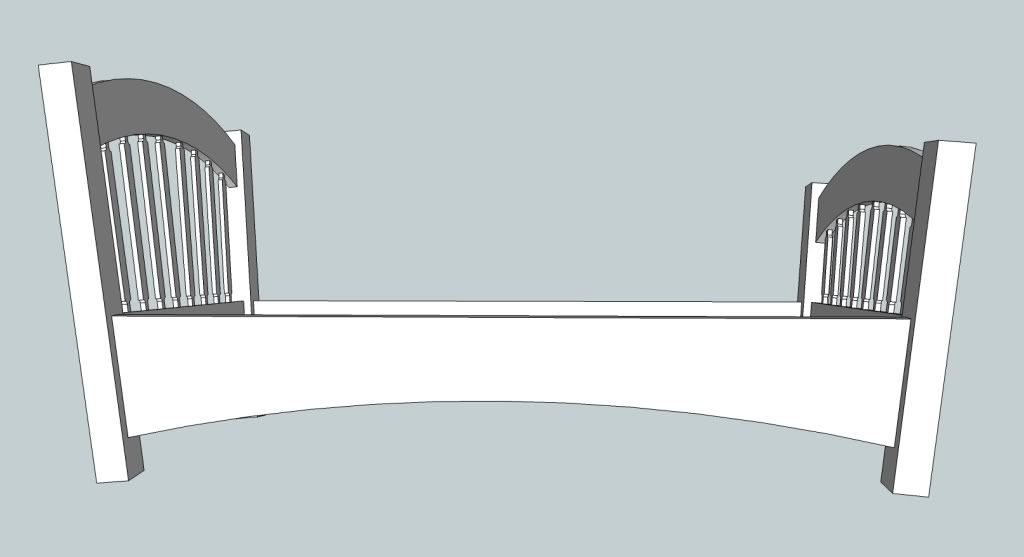

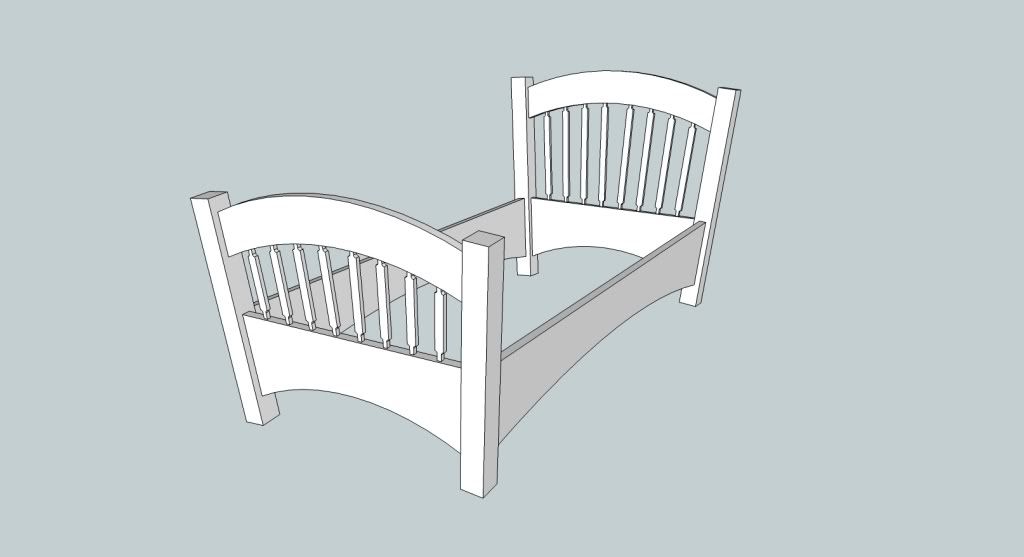

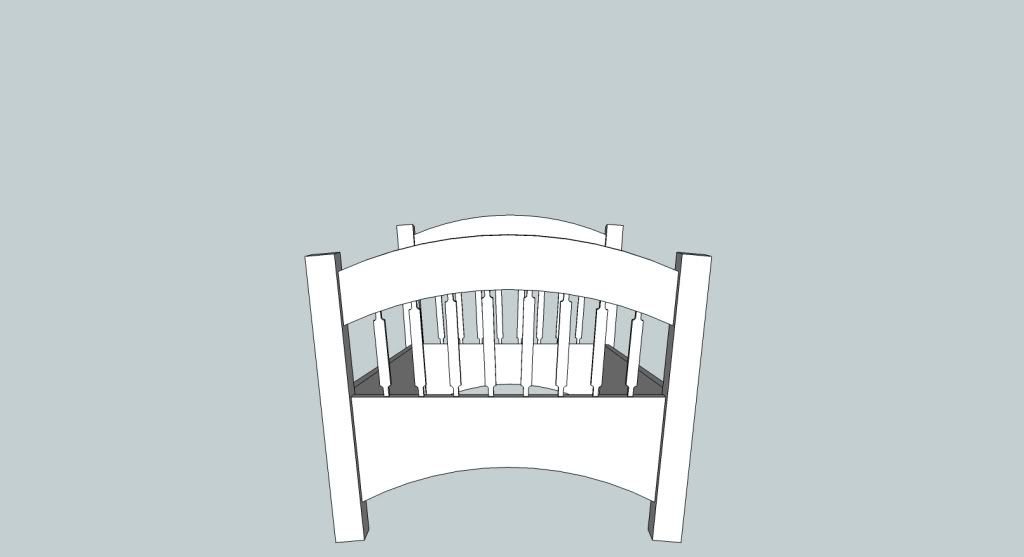

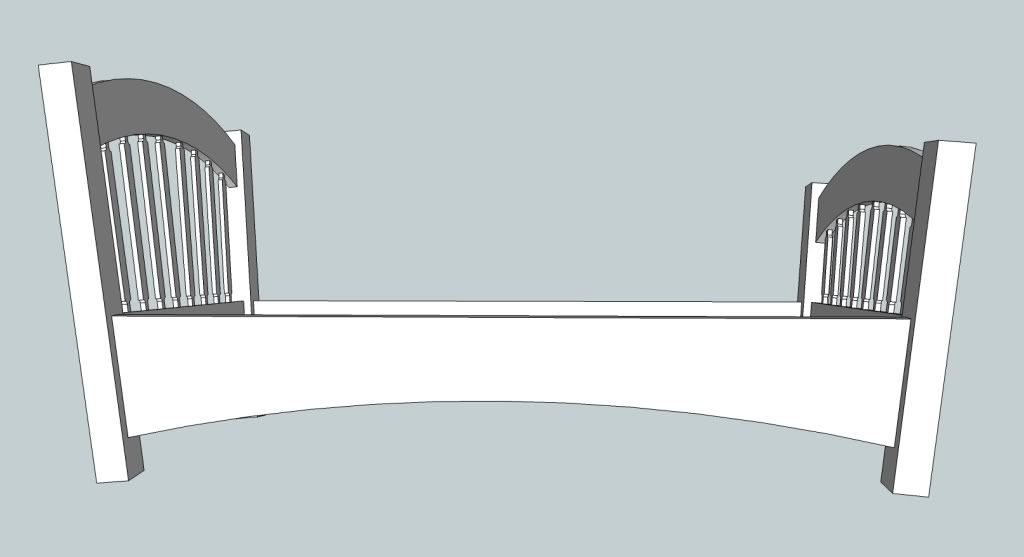

So, I have designed what I want the bed to look like (less some embellishments on the top of the posts that I can't be arsed working out how to draw in sketchup) and went and bought myself about 10cube of Ash (SWMBO's choice...) for making the bed.

The Wardrobe, side table and drawers will follow but given my time constraints and current workshop time the bed is most important.

So, here's the bed design...

And here's the stack of timber I picked up on Monday. Not sure whether it was a good deal or not but I'm limited for decent timber places that will even talk to me as a hobbiest so this lot cost me £218 (average around £21 per cube).

I am hoping to get into the 'shop this evening to face it all up and start organising my cuts to get the best grain matching and go from there.

Hopefully you can help me along the way...Heaven knows I'll need it

As always, comments on desing, construction or anything else always welcomed.

Well, we are a single income household now she's a housewife so need to be frugal!!!

So, I have designed what I want the bed to look like (less some embellishments on the top of the posts that I can't be arsed working out how to draw in sketchup) and went and bought myself about 10cube of Ash (SWMBO's choice...) for making the bed.

The Wardrobe, side table and drawers will follow but given my time constraints and current workshop time the bed is most important.

So, here's the bed design...

And here's the stack of timber I picked up on Monday. Not sure whether it was a good deal or not but I'm limited for decent timber places that will even talk to me as a hobbiest so this lot cost me £218 (average around £21 per cube).

I am hoping to get into the 'shop this evening to face it all up and start organising my cuts to get the best grain matching and go from there.

Hopefully you can help me along the way...Heaven knows I'll need it

As always, comments on desing, construction or anything else always welcomed.