motownmartin

Established Member

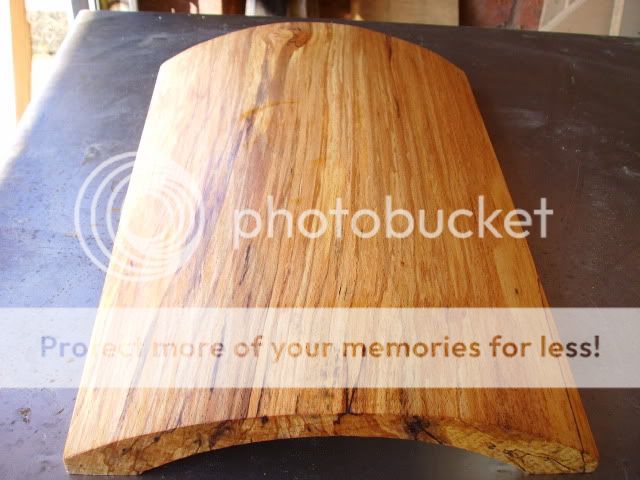

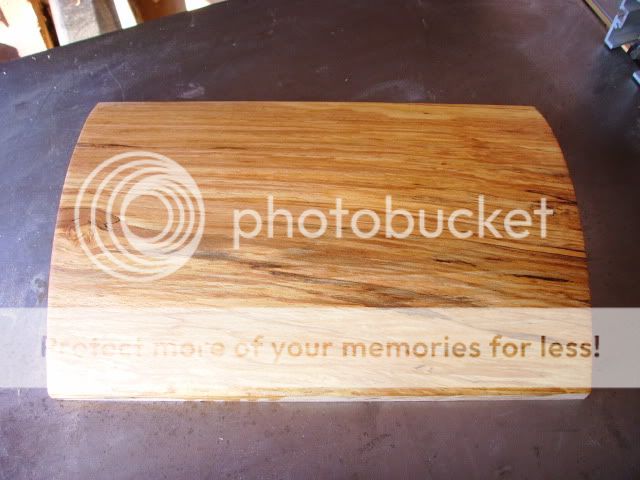

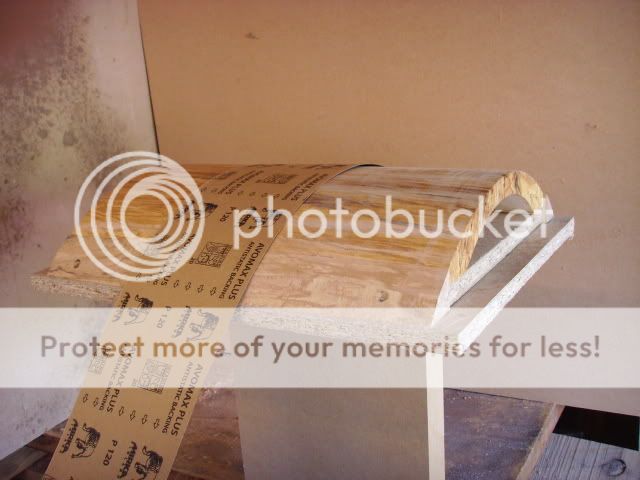

I have finally finished designing my competition entry, there are quite a few challenges for me within the project which are a curved lid, wooden hinges wooden latch/catch and a double box joint.

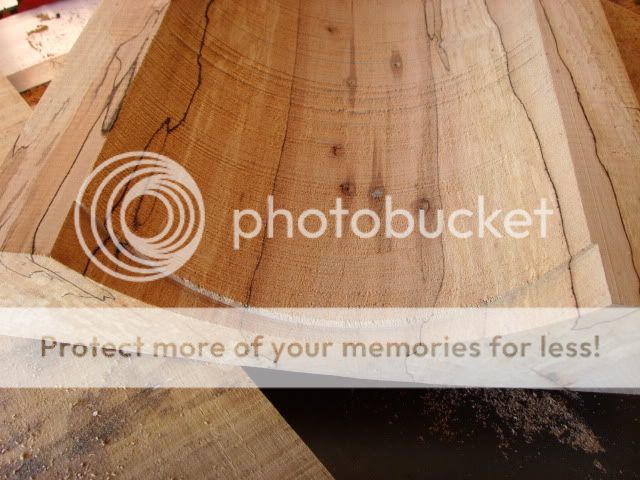

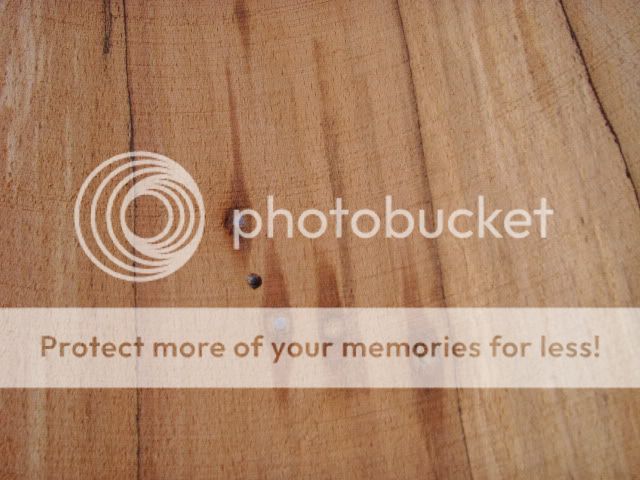

The box will be made from Oak and Spalted Beech, it will be big enough to hold size A4 paper and deep enough to hold a number of items that are precious to one.

The design of the latch/catch is not final yet, I think it will have to be trial and error to see what will work best. The latch is shown in the first drawing and has been designed to look like the hinges which are shown in the second drawing.

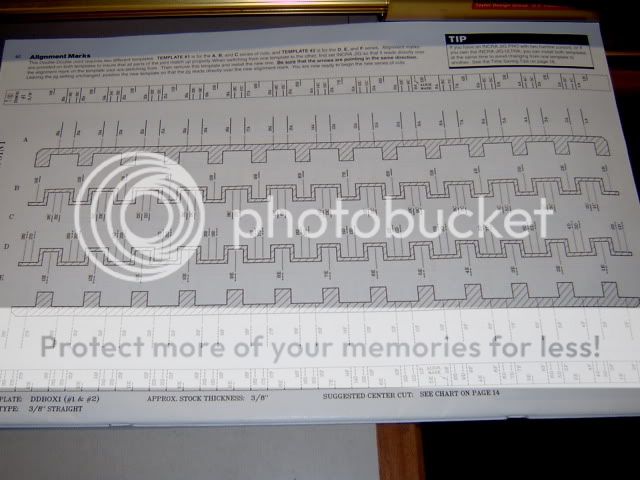

This third drawing shows a closer view of the double box joint which has a border around the first cut with the end grain showing, I am very nervous about getting this right but will show the progress in this thread.

The box will be made from Oak and Spalted Beech, it will be big enough to hold size A4 paper and deep enough to hold a number of items that are precious to one.

The design of the latch/catch is not final yet, I think it will have to be trial and error to see what will work best. The latch is shown in the first drawing and has been designed to look like the hinges which are shown in the second drawing.

This third drawing shows a closer view of the double box joint which has a border around the first cut with the end grain showing, I am very nervous about getting this right but will show the progress in this thread.