motownmartin

Established Member

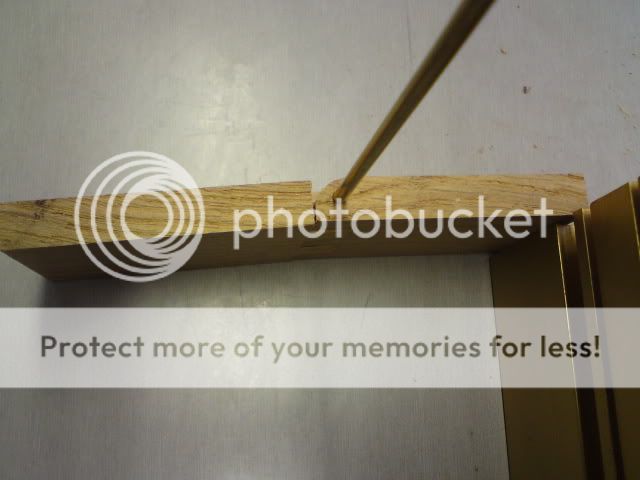

On with the cutting, the first cuts are the A's and the F's, A for the end boards and F for the side boards, I always place an extra board on both sides when cutting like so

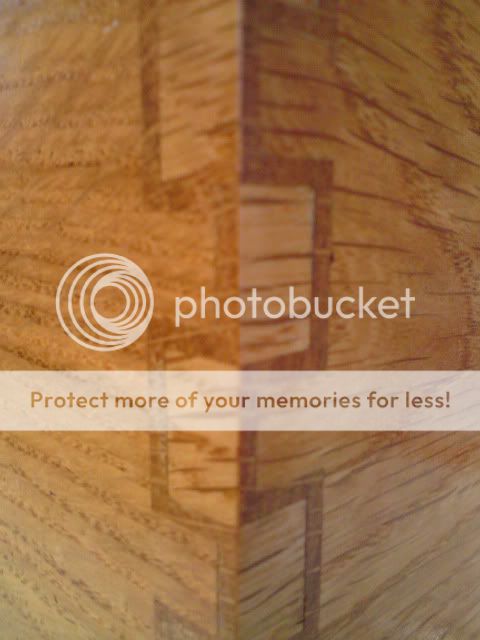

The B & E cuts are cut along the length of a board then cut to size before glueing into position like the next series of pics suggest

I can't do anymore until the glue dries, maybe tomorrow.

The B & E cuts are cut along the length of a board then cut to size before glueing into position like the next series of pics suggest

I can't do anymore until the glue dries, maybe tomorrow.