July Challenge Decorated platter ( Rules /Requirements / Judges Criteria )

Our Judge for July will be Barry ( Thanks Barry )

Any wood type

Any size

Up to 3 different wood types will be allowed , but not multiple segmented work

The Judges requirements

The platter must be lathe turned and must be decorated ( any undecorated entry's will not be judged )

The platter must be a Platter and not a bowl ( entry's that look more like bowls with raised rims will not be judged )

Decoration allowed in this challenge will be as listed below

1, Carving

2, Piercing

3, Colouring

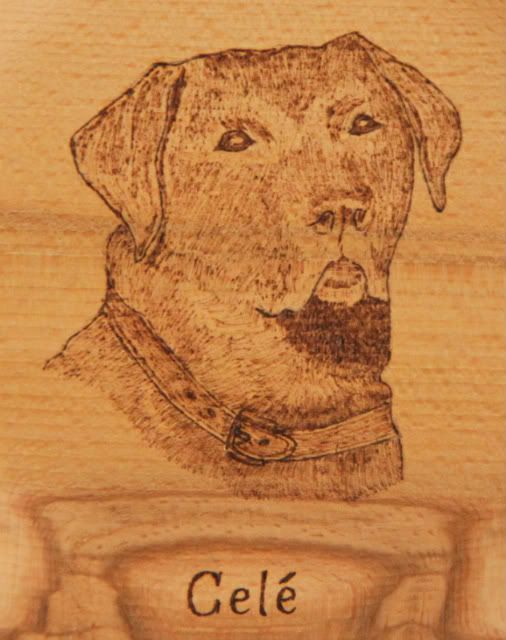

4, Burning ( Including Pyro work )

5, Texturing

Hygiene will not be part of the Judging as the completed platter could be used purely as a decorative / artistic table center piece

I will be judging the artistic / design elements and quality of workmanship of the completed platter

NO Critique or comments on any work until August Please, After the Judging and results.

Please state item size, width and height and wood type used if known and a little about the techniques applied when producing the Platter (this helps the judge)

The Judges decision is final. ( I hope )

Please post 3 images of your work

1 side profile

1 looking down from above

1 close up of a part / design element you are particularly proud of

Image size please use image size 640 x 480 0.3 mp, same as previous months

Please notify me your entries are ready by 10 pm on the 27th July after this time the thread will be locked

Entry’s to be uploaded from 10pm on 27th July up until 10pm on the 29th July after this time the thread will be locked for Judging

Results will be given on or before 31st July

Holidays

If you are going to be away when its time to post up your entries please either send them to me or Chas and we will upload for you so you don’t miss out on judging

Have fun and think safety. Allen

PS , I hope this meets with everyone's approval , if not please PM me ASAP

Our Judge for July will be Barry ( Thanks Barry )

Any wood type

Any size

Up to 3 different wood types will be allowed , but not multiple segmented work

The Judges requirements

The platter must be lathe turned and must be decorated ( any undecorated entry's will not be judged )

The platter must be a Platter and not a bowl ( entry's that look more like bowls with raised rims will not be judged )

Decoration allowed in this challenge will be as listed below

1, Carving

2, Piercing

3, Colouring

4, Burning ( Including Pyro work )

5, Texturing

Hygiene will not be part of the Judging as the completed platter could be used purely as a decorative / artistic table center piece

I will be judging the artistic / design elements and quality of workmanship of the completed platter

NO Critique or comments on any work until August Please, After the Judging and results.

Please state item size, width and height and wood type used if known and a little about the techniques applied when producing the Platter (this helps the judge)

The Judges decision is final. ( I hope )

Please post 3 images of your work

1 side profile

1 looking down from above

1 close up of a part / design element you are particularly proud of

Image size please use image size 640 x 480 0.3 mp, same as previous months

Please notify me your entries are ready by 10 pm on the 27th July after this time the thread will be locked

Entry’s to be uploaded from 10pm on 27th July up until 10pm on the 29th July after this time the thread will be locked for Judging

Results will be given on or before 31st July

Holidays

If you are going to be away when its time to post up your entries please either send them to me or Chas and we will upload for you so you don’t miss out on judging

Have fun and think safety. Allen

PS , I hope this meets with everyone's approval , if not please PM me ASAP