Hi there. I've recently watched the scroll saw threads and thought its about time i had a go myself. I successfully cut out a small key ring and name plate. i'm using a jet jss-16 saw.

I was using axminster blades with pins and they worked o.k.

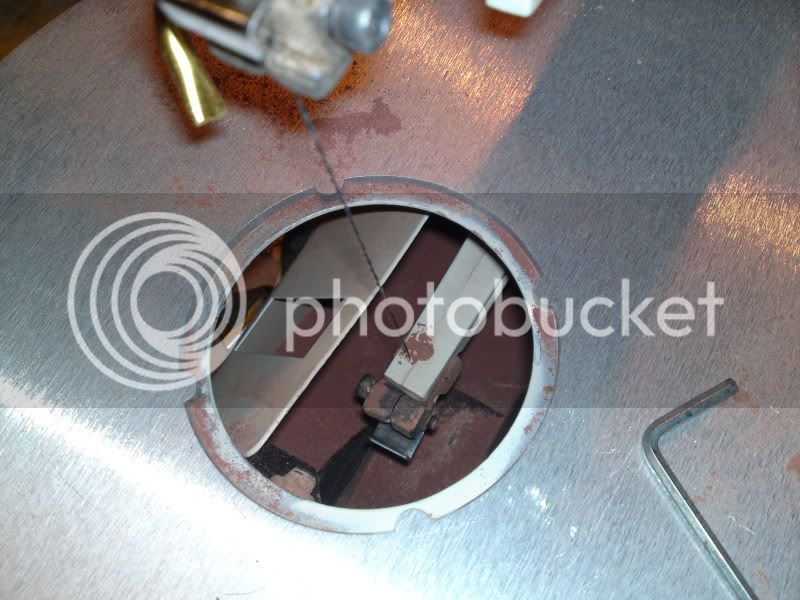

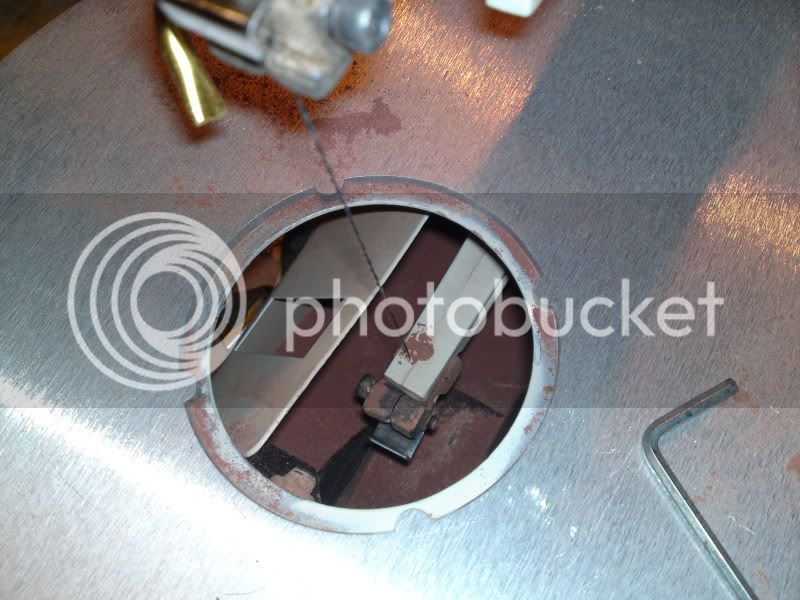

From reading posts, i learned that from buying better blades, a better finish might be given. I bought a multi pack of Olson plain end blades to try (pinless variety) but i cant get them to hold in the scroll saw. Its almost like the clamp bit wont tighten up enough to grip the blade.

I was planning on using them for cutting out this, so chose the pinless version to be able to feed through a small hole.

The instruction book says it will cater for pinned or pinless blades, but i'm having real problems with the pinless ones. I managed to get them to come out 5-10 times trying. didn't break a single blade in the process so they must be much better quality than the cheapys.

Any help would be greatly appreciated :wink:

Simon

I was using axminster blades with pins and they worked o.k.

From reading posts, i learned that from buying better blades, a better finish might be given. I bought a multi pack of Olson plain end blades to try (pinless variety) but i cant get them to hold in the scroll saw. Its almost like the clamp bit wont tighten up enough to grip the blade.

I was planning on using them for cutting out this, so chose the pinless version to be able to feed through a small hole.

The instruction book says it will cater for pinned or pinless blades, but i'm having real problems with the pinless ones. I managed to get them to come out 5-10 times trying. didn't break a single blade in the process so they must be much better quality than the cheapys.

Any help would be greatly appreciated :wink:

Simon