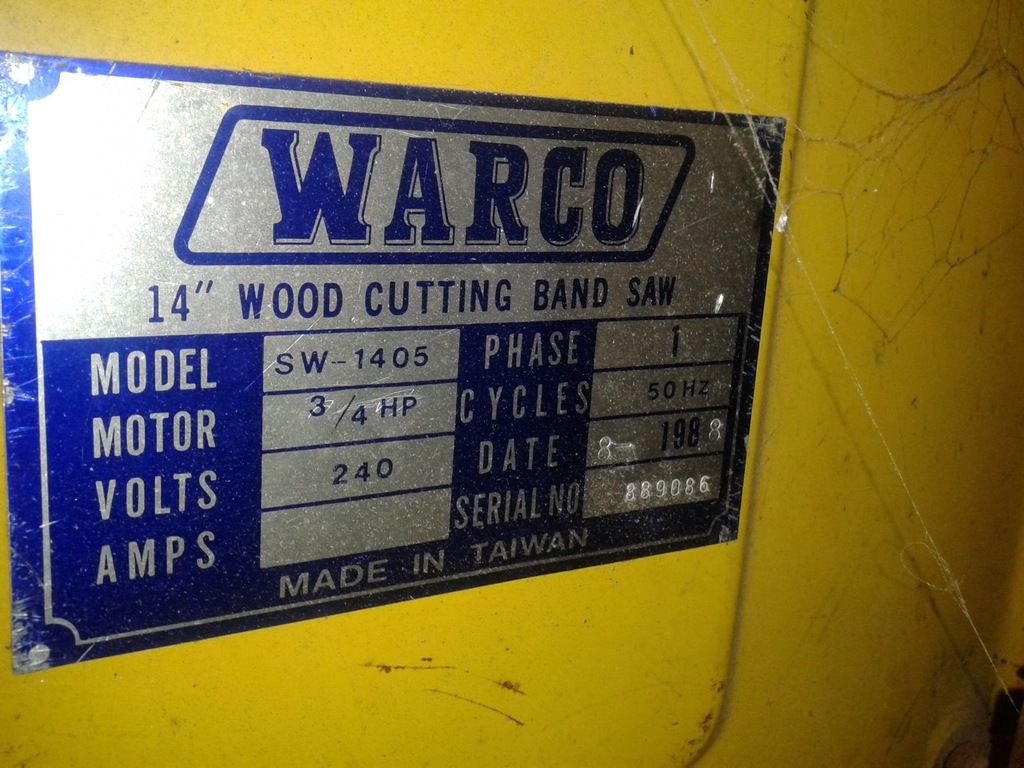

I have one of these -

Also sold as -

etc.

Regardless...

I want a blade for it for straight cross cuts on thin (1/2 and below) hardwood. I do not need to cut tight, if any, curves. I would like a good finish to the cut, but do not want it to burn its way though!

I found this on ebay -

https://www.ebay.co.uk/itm/STARRETT...795062?hash=item4410923b76:g:wK4AAOSwvg9XbUuJ

Description -

STARRETT 2405MM / 95" / 7FT 10.3/4" X 5/8" X 14 RAKER BANDSAW BLADE CARBON

Is that the sort of thing i want, or is that going to be too high tpi? And is the 5/8 width going to be a help or a hinderence?

Ive done various searches, and it seems like the sort of thing i should buy, but if someone could just confirm, that would be great!

Thank you.

Also sold as -

etc.

Regardless...

I want a blade for it for straight cross cuts on thin (1/2 and below) hardwood. I do not need to cut tight, if any, curves. I would like a good finish to the cut, but do not want it to burn its way though!

I found this on ebay -

https://www.ebay.co.uk/itm/STARRETT...795062?hash=item4410923b76:g:wK4AAOSwvg9XbUuJ

Description -

STARRETT 2405MM / 95" / 7FT 10.3/4" X 5/8" X 14 RAKER BANDSAW BLADE CARBON

Is that the sort of thing i want, or is that going to be too high tpi? And is the 5/8 width going to be a help or a hinderence?

Ive done various searches, and it seems like the sort of thing i should buy, but if someone could just confirm, that would be great!

Thank you.