Hi Dick

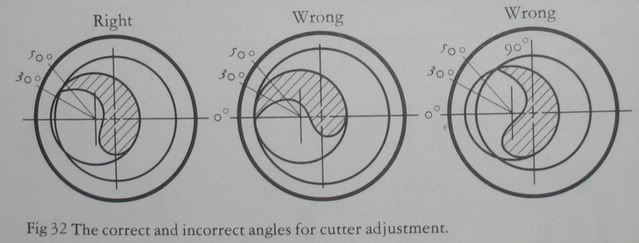

I think you're going to struggle on this one. Many Interwood pin routers were/are used on straight template copy work so concentric profile cutters (the type used in portable routers) aren't much use. Interwood routers were often not used with a concentric collet and nut at all, instead Interwood sold the concept of an eccentric chuch used with a single-flute cutter which could be held at various angles to vary the width of cut. With this system it was claimed that the eccentric cutter system required just 32 cutters (and 15 eccentric chucks) to cut any diameter from 2 to 36mm (in 0.5mm increments) as opposed to some 70 2-flute concentric cutters and that the chucks could be used to compensate for tool wear (very important in industry)

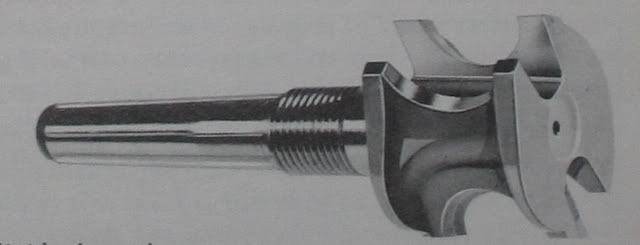

For example a #7 eccentric chuck could be used with an 18mm cutter to produce a sweep of 23 to 24mm. These eccentric chucks are tapered, Morse Taper #2 in fact, and are screwed into the end of the motor spindle directly using an open ended wrench. This method of holding is why the collet/nut sets from Interwood (Allwood) are so expensive (mind you Wadkin C-type concentric collets aren't that much cheaper).

A wide range of HSS single-flute eccentric profile cutters were also sold and some companies using Interwood routers used to grind their own profile cutters on a precision cutter grinder. It may be worth bearing in mind that the Interwood pin router was designed as a volume production machine which was often set up for long continuous runs so some machines would only ever have had a small range of cutters installed throughout their working life

The system also allowed for flat knife chucks and even a miniature Whitehill-pattern cutterblock (both now illegal under current tooling legislation). I've also seen quite a few brazed carbide tools made up specially for the Interwood routers. Again these are designed to screw straight into the tapered hollow in the spindle nose:

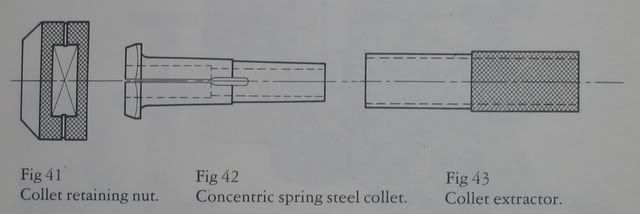

I've got a few spare eccentric chucks (but no spare balancing roll), but concentric collets/nut sets I don't have. So the only thing I can suggest is that you ring round a few machinery dealers and see if you can come up with some that way, however the Interwood router is really not very common these days - the onward march of CNC routers and Italian machines in the 1980s and 1990s killed them off. What I would suggest is that if or when you do get hold of a collet you invest in a collet extractor as well - they can make getting the collet out of the nut so much easier

Scrit