- Joined

- 19 Mar 2007

- Messages

- 5,295

- Reaction score

- 411

Well, for the forth time really. I love turning lamps. Angle poise to be precise and this is the biggest one yet.

Beech stem and arm peices, oak base and leylandii shade. I was given a not very nice looking lump of oak on a visit to a wood supplier in Carcassonne a couple of years back when I bought a couple of beech planks, 2" x 8" x 10' for some other job. I have some of the beech left over, so I decided to make this lamp.

The base is about 12" diameter and took 1/2 of the oak

And that just fitted over the bars on my Record CL1 lathe. I had no idea if it would be OK, but I thought what the hell? I think it turned out well.

Next, the upright stem had to be cut to slightly less than 36" because of the length of the lathe bed. Two peices make uou the stem. Each of the uprights were then cut in 2 length ways and a groove routed out to take the cable, then glued back together. That ensures that the hole is dead centre, plus I ain't got a drill that long! I roughed the stem parts with my roughing gouge. I tried to finish it with my 1" oval skew, but it kept ripping the grain out and that skew IS sharp. I think that it must have been the lay of the grain although I haven't come across that before?

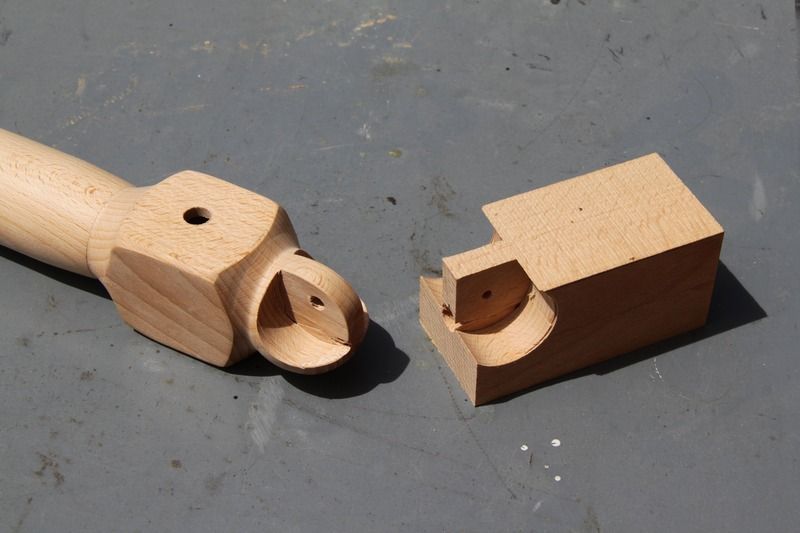

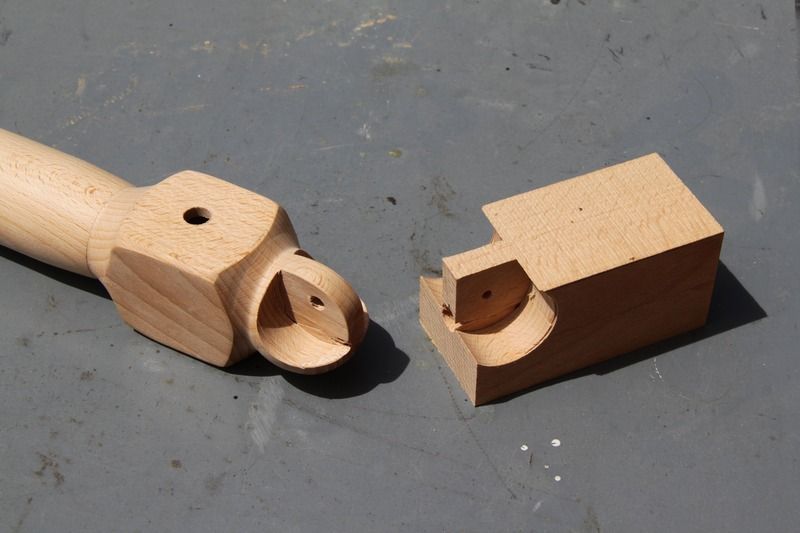

I put a contrasting spalted beech ring in the join of the 2 parts. The stem is quite plain other than that. Next, the top arms. The other lamps I have done have had one solid and one split arm, but I wanted to do both as solid. So I cut each arm down the centre again, routed the groove and glued back together, but on one I stopped the groove short of the ends and drilled in from the side. This arm would be the 'male' and slotted into the 'female' fork.

With a bit cut off of the stem I used it to house the switch and for the bottom arm to hinge on. I used the final waste bit to make a pattern to drill the 'hinge'. Sounds odd, but it worked fine. The hinge was cut with a Forstner bit.

Then it was glued in place on the stem. It doesn't show there but the grain lines up nicely too.

The shade was fun? And a plug was turned to cover the back of the switch mount and one for the base hole where the cable is fed out through the base

A 'saddle' cut and turned to mount the shade, that's a piece of ash I had lying around

All wired up ready to assemble. I thought I would have trouble feeding the cable through the 'stopped' hole arm, but it was straight forward and no problem

It all fits together well

And I am really pleased with the outcome. I drilled 3 very shallow holes in the base to fit 3 small round clear soft plastic feet. 3 because it will always stand solid especially as one of them is directly to the front where the weight is!

Beech stem and arm peices, oak base and leylandii shade. I was given a not very nice looking lump of oak on a visit to a wood supplier in Carcassonne a couple of years back when I bought a couple of beech planks, 2" x 8" x 10' for some other job. I have some of the beech left over, so I decided to make this lamp.

The base is about 12" diameter and took 1/2 of the oak

And that just fitted over the bars on my Record CL1 lathe. I had no idea if it would be OK, but I thought what the hell? I think it turned out well.

Next, the upright stem had to be cut to slightly less than 36" because of the length of the lathe bed. Two peices make uou the stem. Each of the uprights were then cut in 2 length ways and a groove routed out to take the cable, then glued back together. That ensures that the hole is dead centre, plus I ain't got a drill that long! I roughed the stem parts with my roughing gouge. I tried to finish it with my 1" oval skew, but it kept ripping the grain out and that skew IS sharp. I think that it must have been the lay of the grain although I haven't come across that before?

I put a contrasting spalted beech ring in the join of the 2 parts. The stem is quite plain other than that. Next, the top arms. The other lamps I have done have had one solid and one split arm, but I wanted to do both as solid. So I cut each arm down the centre again, routed the groove and glued back together, but on one I stopped the groove short of the ends and drilled in from the side. This arm would be the 'male' and slotted into the 'female' fork.

With a bit cut off of the stem I used it to house the switch and for the bottom arm to hinge on. I used the final waste bit to make a pattern to drill the 'hinge'. Sounds odd, but it worked fine. The hinge was cut with a Forstner bit.

Then it was glued in place on the stem. It doesn't show there but the grain lines up nicely too.

The shade was fun? And a plug was turned to cover the back of the switch mount and one for the base hole where the cable is fed out through the base

A 'saddle' cut and turned to mount the shade, that's a piece of ash I had lying around

All wired up ready to assemble. I thought I would have trouble feeding the cable through the 'stopped' hole arm, but it was straight forward and no problem

It all fits together well

And I am really pleased with the outcome. I drilled 3 very shallow holes in the base to fit 3 small round clear soft plastic feet. 3 because it will always stand solid especially as one of them is directly to the front where the weight is!