miles_hot":35gu86fi said:

Mike Garnham":35gu86fi said:

miles_hot":35gu86fi said:

HOw do you go about drilling for drawboring?

Miles

Miles,

Remove the tenon, and just start drilling a sort distance away from the point-mark you have just made. The distance varies with your material and the size of your timber & joint.

Mike

Are there any metrics or ways of working out the distance based on the material and the timber / joint size or is this down to experience?

Miles

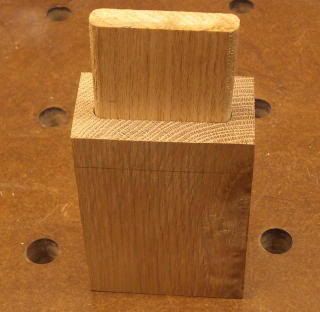

I did some 'testing' on hardwood, 2mm is perfect, 3 mm was too much, you destroy the peg when you try and drive it in. Offcourse this was on the very large t&m joints, smartest thing to do is make a test piece using the same kind of wood you want to construct the drawbore m&t in.

The way I did it was, drill the mortices, put the tenon in, make a center mark with the drill, take tenon out, then I used a centre punch and offset the drill mark at least 2mm.

The first ones I did I lost a lot of time carefully measuring and trying to get the offset holes the perfect distance. Last ones I did I drilled the offset at least 3mm sometimes even more eyeballing the marking out thus making the marking out a lot faster, and then use a round rasp to fine tune them, wich went really fast, talking about one or two strokes with the rasp to get them to the perfect fit.

There is something strangely satisfying to see a m&t joint getting pulled tight when you drive the peg in

One very important detail is, use a knife to cut a point on the pegs before you drive them in.