Wrongfoot

Established Member

I've a nice little honing guide, nothing vintage or special, but it works.

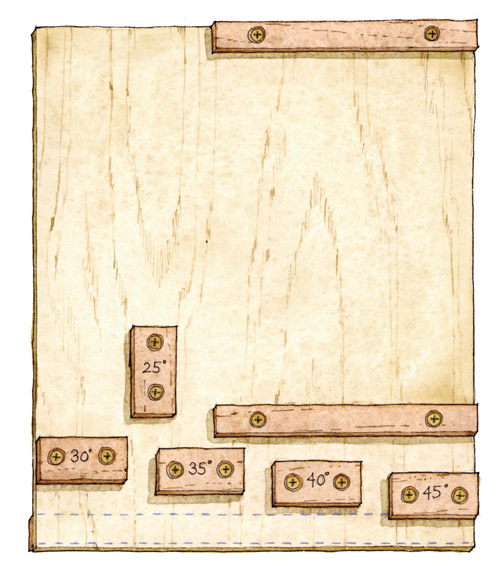

It has protrusions marked on the side for different angles - 50mm for a 25 deg angle and 38mm for 30 deg for plane irons mounted on the top, 40mm for 25 and 30mm for 30 for chisels mounted lower. I don't use it a lot as I mostly freehand my plane irons and chisels.

However I've a few of the Record 405 cutters to dress back to 35 degrees and as there's rust damage to the faces, I'll have to take off a bit... The tungsten steel on those is hard stuff as this'll take a while I'll get tired free handing and no doubt round the iron a bit. I'd prefer not to so I want to dress them back using a guide on a course diamond stone bought for the purpose. Unfortunately those irons need a 35 degree angle... How do I calculate the protrusion for a 35 degree angle?

I can trial it with an angle finder and I may have to do so, but I wondered if anyone knew how to go about the maths for this?

It has protrusions marked on the side for different angles - 50mm for a 25 deg angle and 38mm for 30 deg for plane irons mounted on the top, 40mm for 25 and 30mm for 30 for chisels mounted lower. I don't use it a lot as I mostly freehand my plane irons and chisels.

However I've a few of the Record 405 cutters to dress back to 35 degrees and as there's rust damage to the faces, I'll have to take off a bit... The tungsten steel on those is hard stuff as this'll take a while I'll get tired free handing and no doubt round the iron a bit. I'd prefer not to so I want to dress them back using a guide on a course diamond stone bought for the purpose. Unfortunately those irons need a 35 degree angle... How do I calculate the protrusion for a 35 degree angle?

I can trial it with an angle finder and I may have to do so, but I wondered if anyone knew how to go about the maths for this?