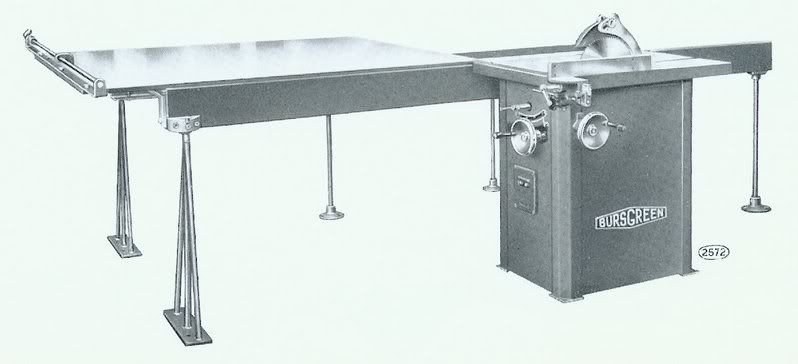

ok I got the space and i suppose I got the money but how much do i need a sliding table?

why do i ask? Well the sip itech saw with S&S clocks in at £450 and the Axy with sliding table clocks in a £600+ now.

I don't do a hell of a lot with sheets but may in the future and wouldn't want to think "Damn wish i had that sliding table".

what you reckon?

why do i ask? Well the sip itech saw with S&S clocks in at £450 and the Axy with sliding table clocks in a £600+ now.

I don't do a hell of a lot with sheets but may in the future and wouldn't want to think "Damn wish i had that sliding table".

what you reckon?