Though I have a Kell and a Veritas MkII, my favourite feels just like an extension of my arms.

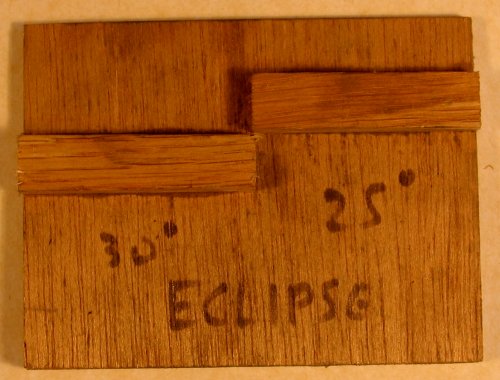

It works well for all bevel angles (up to 90°) and all blade lengths and widths, handles strange shapes (eg router bits); can work at any skew angle (from perpendicular like the Veritas/Kell/Eclipse jigs to parallel like the Harrisson side sharpening jig) and produce flat bevels, microbevels and rounded heels according to application.

The same jig can be used for flattening plane and chisel faces.

One great feature is that once mastered, the same tool holder, USING THE SAME TECHNIQUES can be used for both grinding, sharpening, honing AND for presenting a chisel to the workpiece.

Original concept by Mr and Mrs Hamlin around 45 years ago, it took around nine months to develop, and nearly 43 years before I reaised its worth.

(Yes tongue in cheek - but it really is the best universal jig. )

Of the inorganic jigs, I think all have their forte's, depending on blade length, depth, width and profile. I use Kell/Veritas when I want to do initial or remedial shaping (especially when I want to create/remove a skewed bezel,) as I can sit and curse the telly while I do it. Kell particularly good for short blades or oddly profiled backs (will just about take a RI OBMC for bezel truing) , Veritas good quite good for mindlessly grinding away at a fixed angle/skew. But (I think) I get a better edge with more control when I freehand.

Cheers

Steve Hamlin