A

Anonymous

Guest

Rob

Another thought.

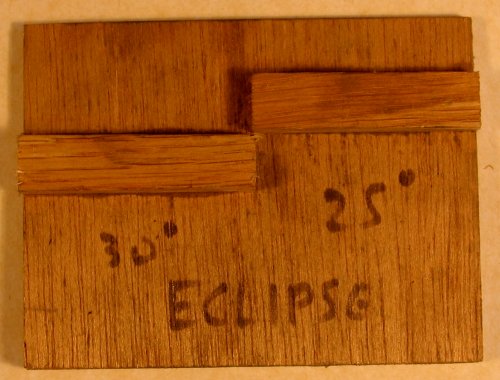

I have looked at the Kell guides and they are truly gorgeous, but it appears that their design is flawed when compared to others on the market.

As far as I can tell, one actually makes wedges for skew blades (I suspect that this is not entirely necessary) and a large one to hold plane irons in place (I suspect this is necessary) whereas other manufacturers have accomplished such tasks without resort to shop-made components.

Another thought.

I have looked at the Kell guides and they are truly gorgeous, but it appears that their design is flawed when compared to others on the market.

As far as I can tell, one actually makes wedges for skew blades (I suspect that this is not entirely necessary) and a large one to hold plane irons in place (I suspect this is necessary) whereas other manufacturers have accomplished such tasks without resort to shop-made components.