[thread hijack alert!]

Cor. I'd forgotten all about that!

I built a cheap cistern into our top bathroom a couple of years ago. This wasn't

just because I'm a cheapskate, but because I wanted a syphon flush (can't stand those EU-flap-valve disasters, and a lever went with the design better than a push button). The only one I could easily get didn't let me arrange the mechanism as I needed to.

It's built-in back-to-front (hangs on the framework, not the wall behind). There's a built-in cupboard bang next to it on the left, and the lever and the inlet valve are both on the right.

Normally, the handle is on the same side as the syphon inside the cistern. It had to have a side-entry valve, otherwise you couldn't maintain it (couldn't get at a service valve underneath because of the boxing-in). So... valve, handle and syphon all needed to be on the right side, but they wouldn't all fit! So I ended up with this:

It's roughly to scale, and you can see it's a right toadstool*. You're looking from the front, through the boxing-in. The handle is out front (obviously), with a long shaft going through into the works. I cut a slot in the lid, so that the bigger pulley could stick out above. That's partly for the aesthetics of the front (handle needs to be up high), partly to ensure a good flush (water level needs to be as high as the syphon allows).

The green circles are the pulleys I needed. They are different sizes so that there is a mechanical advantage - less force needed on the handle for an easier flush. This doesn't mimic the normal arrangement with a crank, because this one is actually a chrome door handle and already has internal springs. they were too strong and I had to fettle the mechanics too. Getting it "just so" was rather a pain.

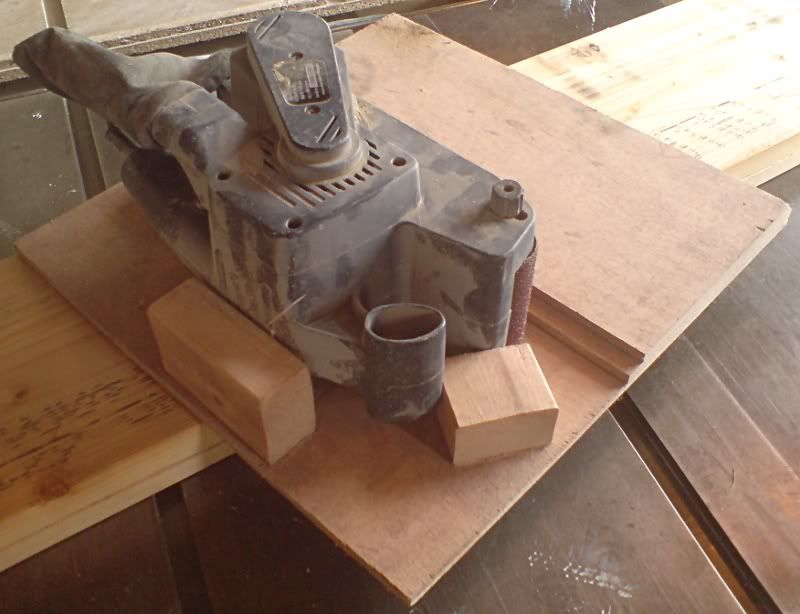

The drawing is wrong: the big pulley does NOT have a central pivot. It's offset. The flush starts with maximum leverage, and as you continue to turn the handle you get more movement and less leverage (the radius increases). It's more like a cam than a pulley really. That's why making the disks was tricky - I couldn't have a central through hole as it would have got in the way later. I

think the smaller one is a double pulley, with two sizes glued together to finally sort out the gearing, but to be honest I've forgotten!

I'll take a pic of the finished arrangement if you're not bored by now, but heck, it's only a toilet!

The V-grooving jig is more interesting, but I'm not sure if I've still got it - that worked really well. My 'small circle jig' for the router table is OK-ish, but I learned enough to make several improvements, and because the original is a bit, er, hostile ("how far can

your router table chuck MDF disks?"), I'd rather wait on that until I've got a better design fully tested.

E.

*no mushroom anywhere! (I've got me coat already).