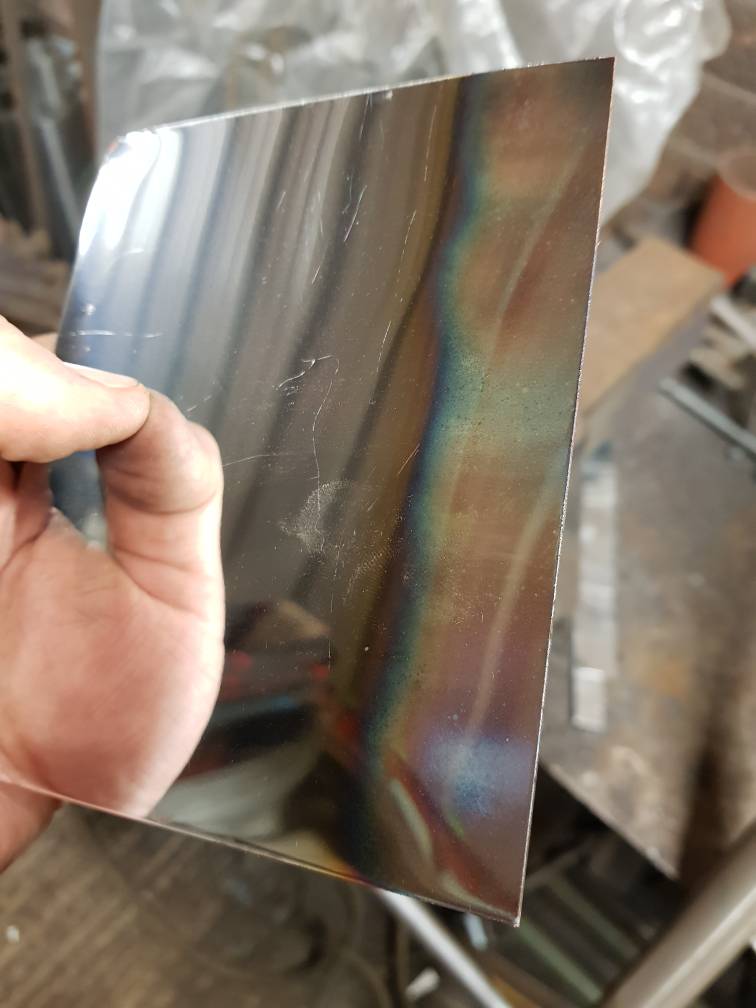

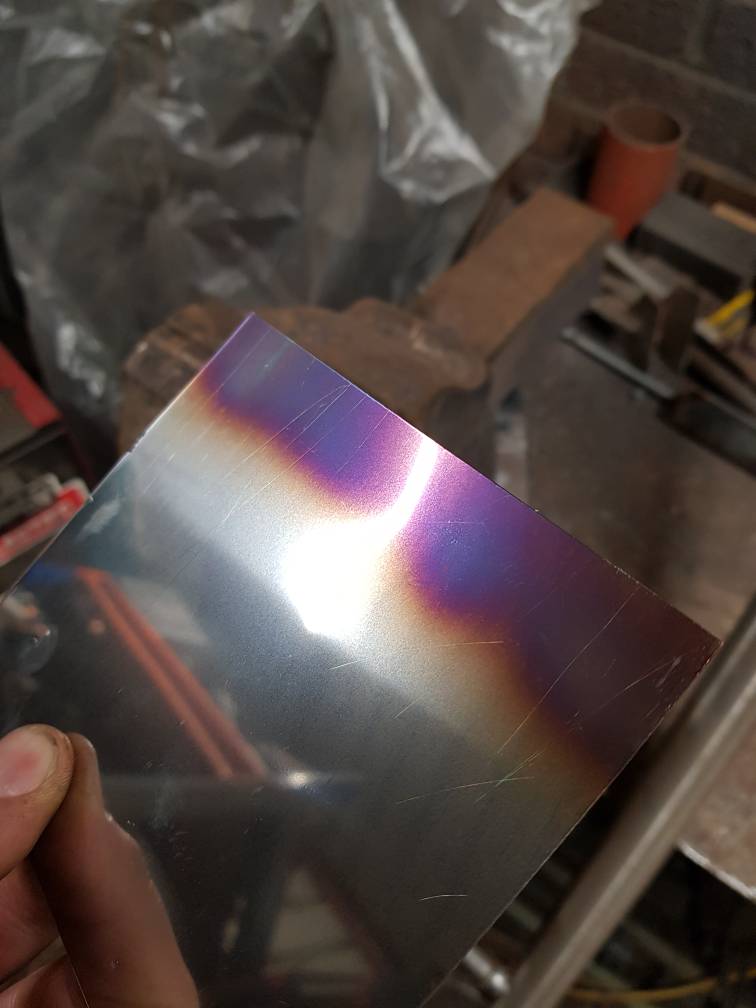

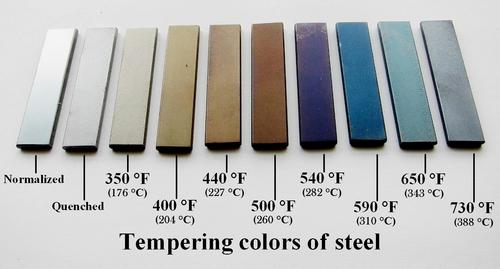

Is is possible to colour stainless steel in the home workshop, ie using a propane or mapp gas blow torch? I want to achieve a blue colour, similar to the image. I need two pieces to be similar, the actual colour isn't vital.

material will be 40mm stainless steel pipe, 50mm long, wall thickness 3mm.

how resilient/stable is the finish to scratches and handling?

the only proper of stainless steel that I need is the lack of corrosion (generally, and in the presence of dry table salt) and lack of staining to oak.

material will be 40mm stainless steel pipe, 50mm long, wall thickness 3mm.

how resilient/stable is the finish to scratches and handling?

the only proper of stainless steel that I need is the lack of corrosion (generally, and in the presence of dry table salt) and lack of staining to oak.