Just a quick update on this thread. I am going back on Tuesday when the customer is back from holiday to take some pics of the kitchen and deliver another couple of things which they asked me to build. I've been working on these since yesterday morning.

A computer unit, in a matching style to the kitchen units. Here i've built and primed the carcass, ready for the doors and face frame to be made up this weekend

I bought some more Beech - 6 lengths between 6" & 8" wide, 8' long. £43 inc VAT, which I thought was pretty good. Nice stuff too

I also have a wine rack to build - this image shows the carcass and the horizontal dividers

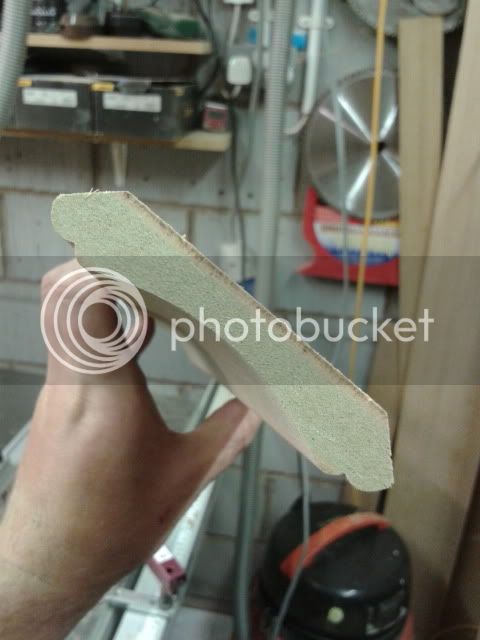

And here are the vertical dividers

Again, a face frame will wrap round the front of the unit. T&G end panel. Granite top. The storage section needs to be removable as the stop cock for the water supply is situated behind the unit #-o

Thanks for looking

Cheers

Karl

A computer unit, in a matching style to the kitchen units. Here i've built and primed the carcass, ready for the doors and face frame to be made up this weekend

I bought some more Beech - 6 lengths between 6" & 8" wide, 8' long. £43 inc VAT, which I thought was pretty good. Nice stuff too

I also have a wine rack to build - this image shows the carcass and the horizontal dividers

And here are the vertical dividers

Again, a face frame will wrap round the front of the unit. T&G end panel. Granite top. The storage section needs to be removable as the stop cock for the water supply is situated behind the unit #-o

Thanks for looking

Cheers

Karl