engineer one

Established Member

slowly i inch my way into the dark world of hand made stuff again.

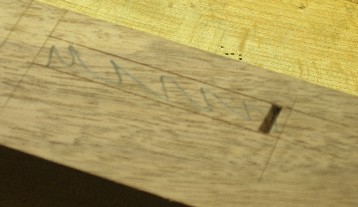

having sort of mastered planing flat panels, and my square legs, the next scary piece if providing at least 12 m/t joints around the frame, apart from the ones to go into the top.

last time i did them by machine, so the question is how do you "guarantee" that you get the mortise holes at the same height on each of the four legs??

i understand that you work to the line, but what happens if you are slightly ham fisted, and go over or is it below the line :?

is there a logic to clamping all four sides together showing the specific faces, and then clamp a block across the bottom so you cannot go below that, or is there a better , more effective way of doing it?

i want to do this by hand, but do have the machinery too, so what's the scoop? please :roll:

paul :wink:

having sort of mastered planing flat panels, and my square legs, the next scary piece if providing at least 12 m/t joints around the frame, apart from the ones to go into the top.

last time i did them by machine, so the question is how do you "guarantee" that you get the mortise holes at the same height on each of the four legs??

i understand that you work to the line, but what happens if you are slightly ham fisted, and go over or is it below the line :?

is there a logic to clamping all four sides together showing the specific faces, and then clamp a block across the bottom so you cannot go below that, or is there a better , more effective way of doing it?

i want to do this by hand, but do have the machinery too, so what's the scoop? please :roll:

paul :wink: