Alf

Established Member

I've been thinking - no, don't run away yet! Anyway, I've been thinking about dovetails and particularly dovetail housings. Possibly prompted by a bit of joinery I saw up in Kent earlier this month (scroll down a bit here). You often hear folks taking about London pattern and other fine-pin dovetails "showing it's hand cut", but no-one as far as I know mentions dovetail housings.

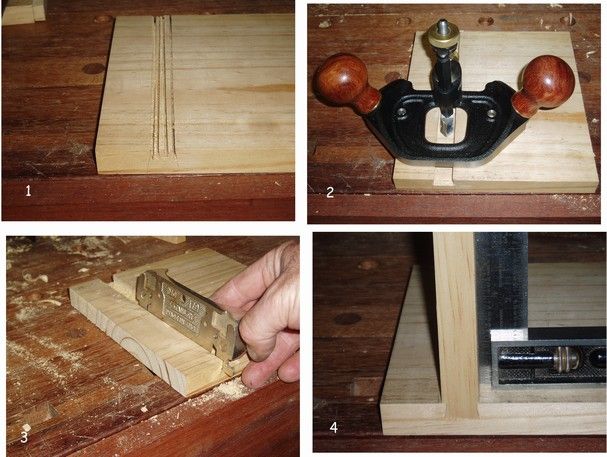

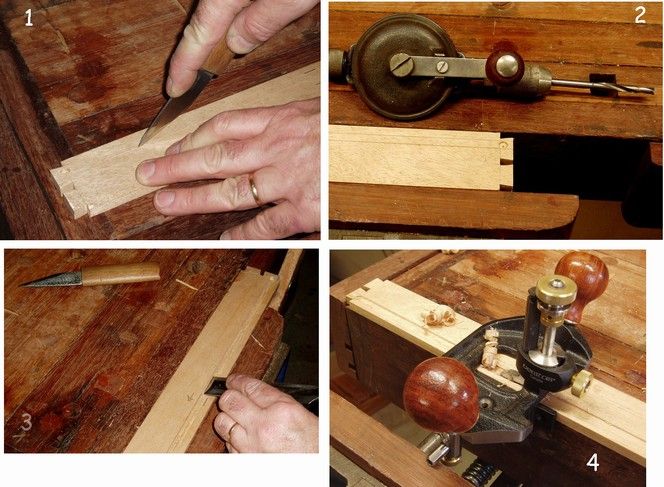

A brief and unscientific flick through some of my books shows a pretty consistant showing of dovetail housings with only one angled side. Now to me that makes a lot of sense; they're hand cut, it's a lot trickier to fine tune a joint with two sloping sides and so forth. Presumably it's more than adequate for the task too? But these days, when the likes of Derek and Jake come up with astoundingly fine examples of hand cut sliding dovetails, they're apparently universally sloped on both sides.

So a few questions, musings, call them what you will.

1. Is there any structural advantage to having a "full" sliding dovetail over a "half", and if yes, is it actually needed?

2. Have we fallen once more into the pit of trying to make hand tool-made stuff look machine-made? Be interested to hear from Jake and Derek if they even gave it a thought. Of course it may be that folks actually prefer the looks of the full dovetail?

3. Should dovetail housings also be done the old-fashioned, a-machine-can't-do-that-way in order to claim "bragging rights"? Discuss.

4. Any other joints skulling about that have been re-thought to make it easy for machinery that we should be reclaiming for hand tools? The stopped groove has always struck as something that's very much a machine task that hand toolers try desperately to replicate instead of going back to the fundamentals, but that's a bit of a different case.

Anyway, I toss out these ramblings just to prove hand tool use doesn't mean you're purely tool fixated. Just about 99.9%... :wink:

Cheers, Alf

A brief and unscientific flick through some of my books shows a pretty consistant showing of dovetail housings with only one angled side. Now to me that makes a lot of sense; they're hand cut, it's a lot trickier to fine tune a joint with two sloping sides and so forth. Presumably it's more than adequate for the task too? But these days, when the likes of Derek and Jake come up with astoundingly fine examples of hand cut sliding dovetails, they're apparently universally sloped on both sides.

So a few questions, musings, call them what you will.

1. Is there any structural advantage to having a "full" sliding dovetail over a "half", and if yes, is it actually needed?

2. Have we fallen once more into the pit of trying to make hand tool-made stuff look machine-made? Be interested to hear from Jake and Derek if they even gave it a thought. Of course it may be that folks actually prefer the looks of the full dovetail?

3. Should dovetail housings also be done the old-fashioned, a-machine-can't-do-that-way in order to claim "bragging rights"? Discuss.

4. Any other joints skulling about that have been re-thought to make it easy for machinery that we should be reclaiming for hand tools? The stopped groove has always struck as something that's very much a machine task that hand toolers try desperately to replicate instead of going back to the fundamentals, but that's a bit of a different case.

Anyway, I toss out these ramblings just to prove hand tool use doesn't mean you're purely tool fixated. Just about 99.9%... :wink:

Cheers, Alf