Random Orbital Bob

Established Member

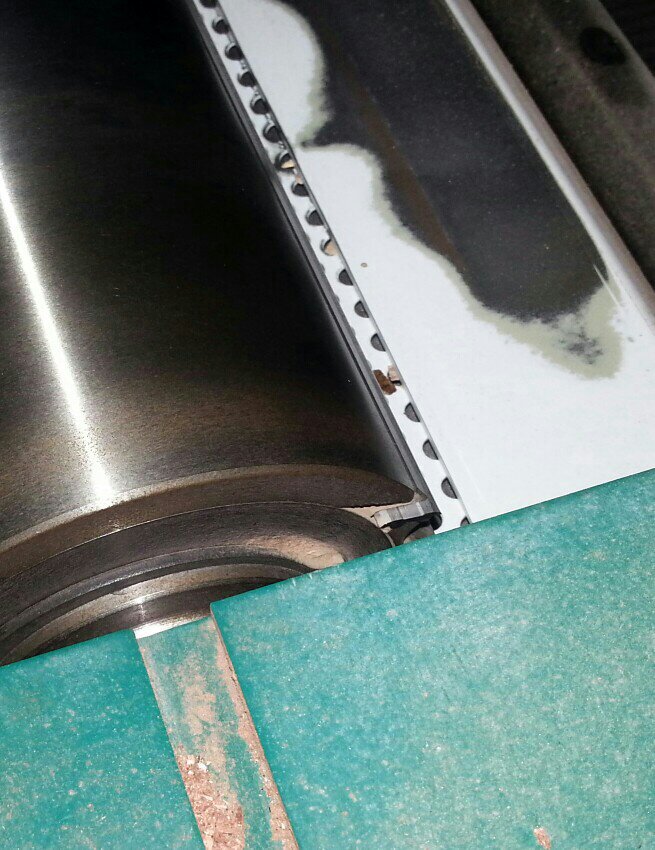

I saw this for the first time today. Each cutter is individually changeable and each has four cutting edges so that's 4 bites of the cherry before you discard them. Also, no knife setting jigs required with these babies. Very sweet indeed

(Mind you at over 2 large for the 12" model it blinkin well had better be good)

(Mind you at over 2 large for the 12" model it blinkin well had better be good)