devonwoody

Established Member

I had an accident last week turning, the mahogany type timber broke off at its edge (to a third of the bowl depth).

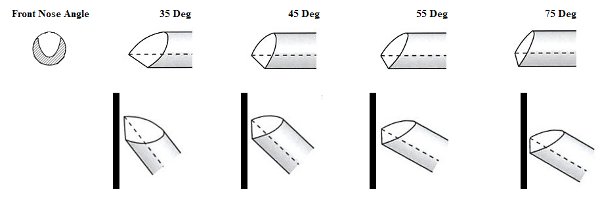

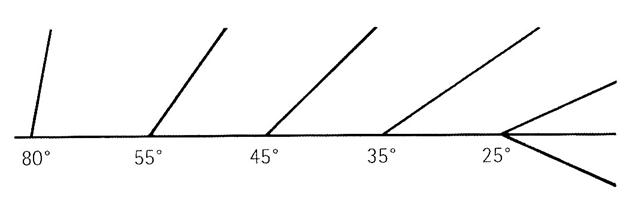

My gouges small medium and large (20mm largest) are all set to 45% bevel.

I definitely laid the bevel to the timber first and pulled the chisel handle up until I got a cut, but each time there was a catch, (well almost every time.)

Is there more bevel on a 55% setting and less chance of catch ups?

My gouges small medium and large (20mm largest) are all set to 45% bevel.

I definitely laid the bevel to the timber first and pulled the chisel handle up until I got a cut, but each time there was a catch, (well almost every time.)

Is there more bevel on a 55% setting and less chance of catch ups?