YorkshireMartin

Established Member

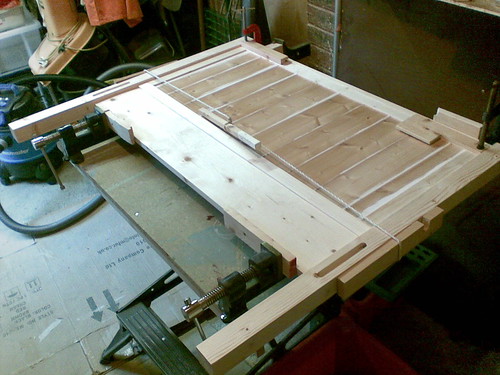

I've been looking at the Irwin Quick Grip range but they are expensive for the size I need. I'll shortly be attempting my first ever glue up on a table which is 1.6m long. So I need something pretty big I think?

I think I read somewhere that people generally make their own from a clamp unit and length of steel pipe, but I haven't seen any clamps in the DIY sheds or online yet.

Whats the best way to go about a large glue up such as this? If it's bar clamps, can anyone recommend a supplier of suitable parts.

Thank you.

I think I read somewhere that people generally make their own from a clamp unit and length of steel pipe, but I haven't seen any clamps in the DIY sheds or online yet.

Whats the best way to go about a large glue up such as this? If it's bar clamps, can anyone recommend a supplier of suitable parts.

Thank you.