Hi all,

I woke up one morning, just a short year before turning 40, and thought it was about time I picked up a craft and put my empty garage to good use.

So off I went and got me some tools and some MDF boards and some looks of pity from the tradesmen behind the counter (oh look at the desk jockey go, with his tender hands and his middle-life crisis. Couldn't he just get a sportscar or an extramarital affair like everyone else?) and started making my first ever project. This was to be a set of cabinets for the utility room, as so often seems to be the case.

These were to be made out of:

- 18mm MDF for the carcass and shelves.

- 12mm board + 6mm trim = 18mm shaker style doors.

- Flush hinges for the doors to be inset.

So far, I am happy with the result and I have learned from my mistakes by measuring twice and cutting thrice.

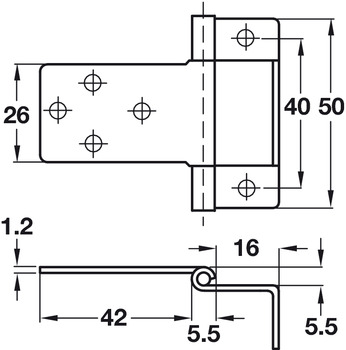

But there is one thing I cannot find the solution to. How to fit "flush" hinges and have the door face actually fit flush. Everything I find online says you do not need mortices with flush hinges but my door panel's face is refusing to sit flush with the frame. It is still inset and fits nicely all round, but its face is not flush to the frame. I initially used straight flush which i replaced as I did not feel comfortable with the screws' "bite" on the edge of the MDF board. With those, the door face was sitting flush. Now that i am using cranked ones (for the added screw to bit on the inside face) I am having this issue. The doors are sticking out by a lot. Do doors need to be thinner than the frame? Do I have to dig the frame-side part of the knuckle into the MDF? Will it still turn if I do?

Any help would be much appreciated.

Many Thanks

I woke up one morning, just a short year before turning 40, and thought it was about time I picked up a craft and put my empty garage to good use.

So off I went and got me some tools and some MDF boards and some looks of pity from the tradesmen behind the counter (oh look at the desk jockey go, with his tender hands and his middle-life crisis. Couldn't he just get a sportscar or an extramarital affair like everyone else?) and started making my first ever project. This was to be a set of cabinets for the utility room, as so often seems to be the case.

These were to be made out of:

- 18mm MDF for the carcass and shelves.

- 12mm board + 6mm trim = 18mm shaker style doors.

- Flush hinges for the doors to be inset.

So far, I am happy with the result and I have learned from my mistakes by measuring twice and cutting thrice.

But there is one thing I cannot find the solution to. How to fit "flush" hinges and have the door face actually fit flush. Everything I find online says you do not need mortices with flush hinges but my door panel's face is refusing to sit flush with the frame. It is still inset and fits nicely all round, but its face is not flush to the frame. I initially used straight flush which i replaced as I did not feel comfortable with the screws' "bite" on the edge of the MDF board. With those, the door face was sitting flush. Now that i am using cranked ones (for the added screw to bit on the inside face) I am having this issue. The doors are sticking out by a lot. Do doors need to be thinner than the frame? Do I have to dig the frame-side part of the knuckle into the MDF? Will it still turn if I do?

Any help would be much appreciated.

Many Thanks