WoodAddict

Established Member

I've been lucky enough to have been given a nice little selection of hardwood "offcuts" recently. The majority of which was from MotownMartin so thanks again for that :wink:

I wanted to use it for practising joints and general sizing/thicknessing. I thought the best way to practice would be to actually make something! So here we are......... I've still got no bench :roll: for a couple of reasons, so until then I'm working on the floor and various boxes and tool boxes which isn't the best but I'll hopefully have the bench sorted when it comes to cutting the joints and assembling.

I chose an assortment of pieces based on size and looks, then I thicknessed a piece to around 6mm for the box sides....

This particular piece had a nice little detail on one edge so I'll shamelessly be leaving this on as I think it could look nice when it's finished :lol:

:lol:

I did the sizing and thicknessing all on the bandsaw with my new "Tuff-Saws" blade! 8) and very nice it is too, Thanks Ian!

I really must get some dust extraction sorted for this! I was wearing a mask and I left the door open but it's not ideal.

I got a few bits cut to size, it's the first time I've tried the BS with any kind of precision and it seems pretty good so far!

The darker wood in the last picture will be for the drawer in the bottom, the thin square piece will be for the hinge piece of the lid. I'll be hinging with dowels which is why the back piece is lower than the side pieces.

I've not done a drawing of what the box will look like as I'm kind of just going with it and seeing what happens. My basic plan is a drawer on the bottom and a top section with a lid. I'll be joining the box sides and the drawer with finger joints. Basic but hopefully effective. If you guys can help out with wood ID as I go I'd be very greatfull as I'm not sure what any of it is. :roll:

Any general pointers or observations welcome.........

Thanks

I wanted to use it for practising joints and general sizing/thicknessing. I thought the best way to practice would be to actually make something! So here we are......... I've still got no bench :roll: for a couple of reasons, so until then I'm working on the floor and various boxes and tool boxes which isn't the best but I'll hopefully have the bench sorted when it comes to cutting the joints and assembling.

I chose an assortment of pieces based on size and looks, then I thicknessed a piece to around 6mm for the box sides....

This particular piece had a nice little detail on one edge so I'll shamelessly be leaving this on as I think it could look nice when it's finished

I did the sizing and thicknessing all on the bandsaw with my new "Tuff-Saws" blade! 8) and very nice it is too, Thanks Ian!

I really must get some dust extraction sorted for this! I was wearing a mask and I left the door open but it's not ideal.

I got a few bits cut to size, it's the first time I've tried the BS with any kind of precision and it seems pretty good so far!

The darker wood in the last picture will be for the drawer in the bottom, the thin square piece will be for the hinge piece of the lid. I'll be hinging with dowels which is why the back piece is lower than the side pieces.

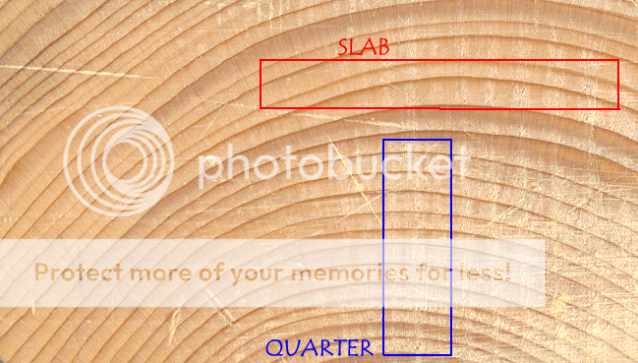

I've not done a drawing of what the box will look like as I'm kind of just going with it and seeing what happens. My basic plan is a drawer on the bottom and a top section with a lid. I'll be joining the box sides and the drawer with finger joints. Basic but hopefully effective. If you guys can help out with wood ID as I go I'd be very greatfull as I'm not sure what any of it is. :roll:

Any general pointers or observations welcome.........

Thanks