devonwoody

Established Member

The temperature in the workshop has just been right the last three days.

So I have started the new season making another of my old favourites.

A pentidy. A daughter is visiting Easter so I have got to get it done, I gave the last one away so she got left out.

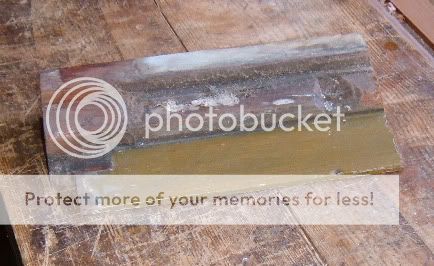

5ft length of 7x2" American Ash.

A 80 mm width ripped off and reduced to 24 inch length ready for the planer/thicknesser.

Then put through the bandsaw and got 2 pieces 12mm and 1 piece 20mm thick after thicknessing again, so no wastage out of the original 50 mm starting thickness.

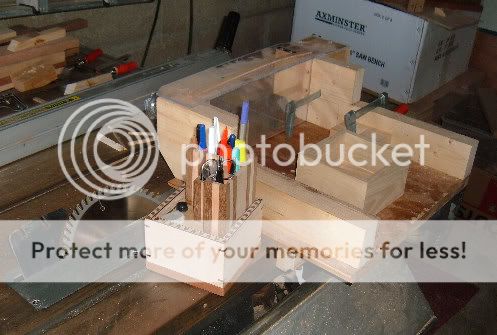

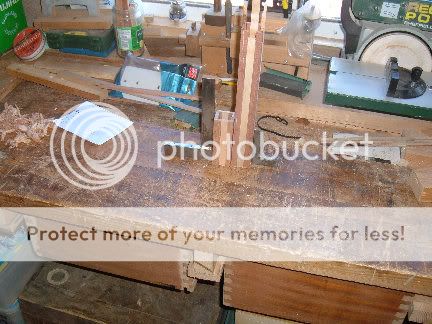

Put in a dado for platform to be inserted in box later whilst in its longest length. Then cut to 4 equal lenths on the sled.

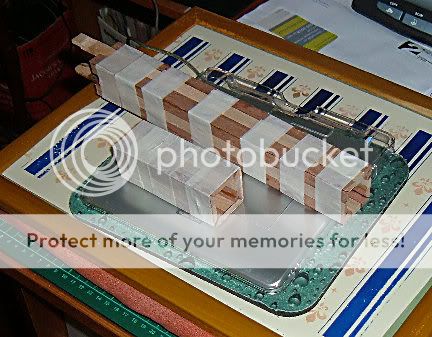

Then mited each corner on the sled I made to do mitre cuts.

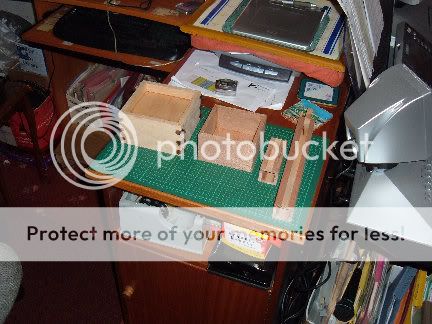

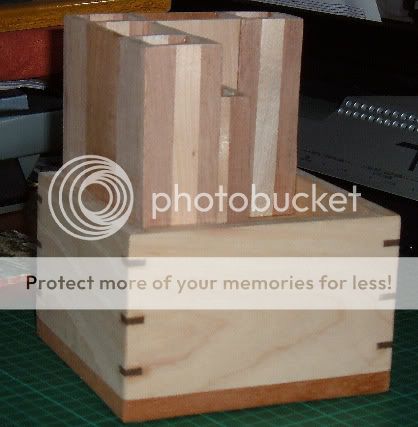

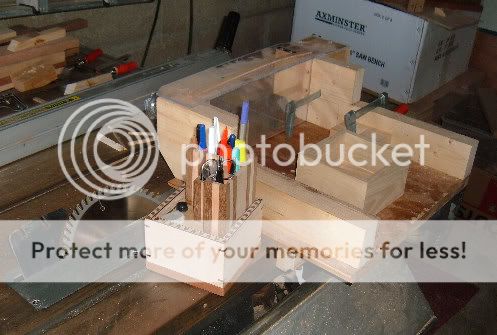

The box I am copying.

So I have started the new season making another of my old favourites.

A pentidy. A daughter is visiting Easter so I have got to get it done, I gave the last one away so she got left out.

5ft length of 7x2" American Ash.

A 80 mm width ripped off and reduced to 24 inch length ready for the planer/thicknesser.

Then put through the bandsaw and got 2 pieces 12mm and 1 piece 20mm thick after thicknessing again, so no wastage out of the original 50 mm starting thickness.

Put in a dado for platform to be inserted in box later whilst in its longest length. Then cut to 4 equal lenths on the sled.

Then mited each corner on the sled I made to do mitre cuts.

The box I am copying.