A new workbench has been on the cards for a long time but now after finally completing all my pre-winter punch-points and with a 3-day weekend coming up with no other commitments the time’s now right.

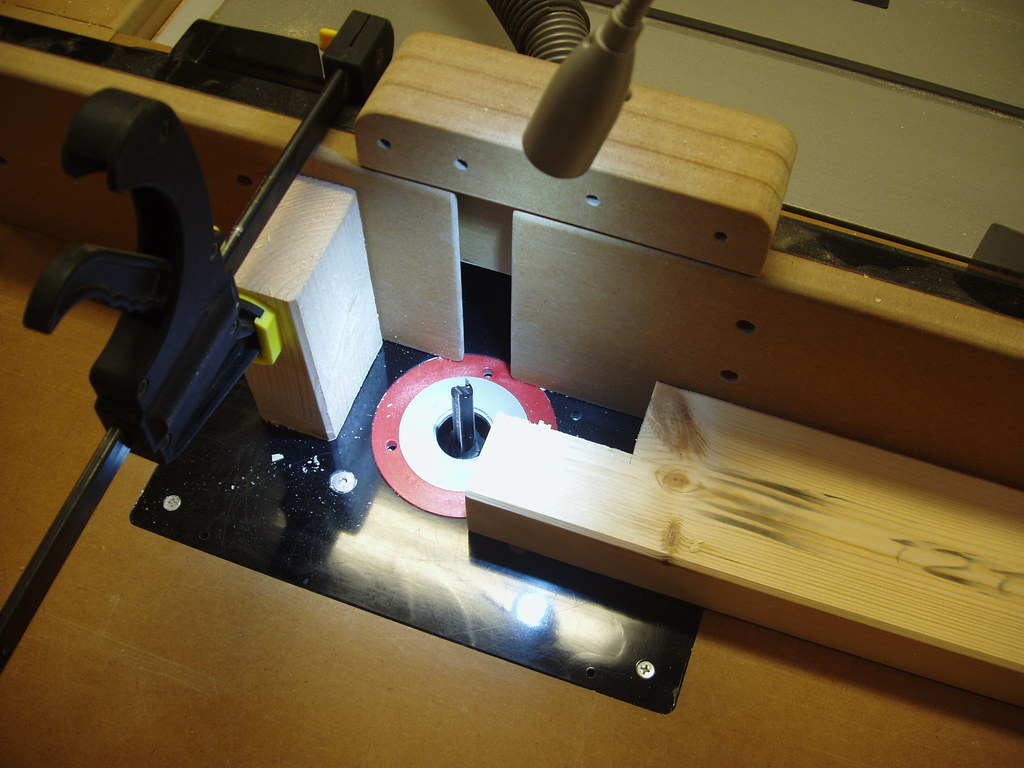

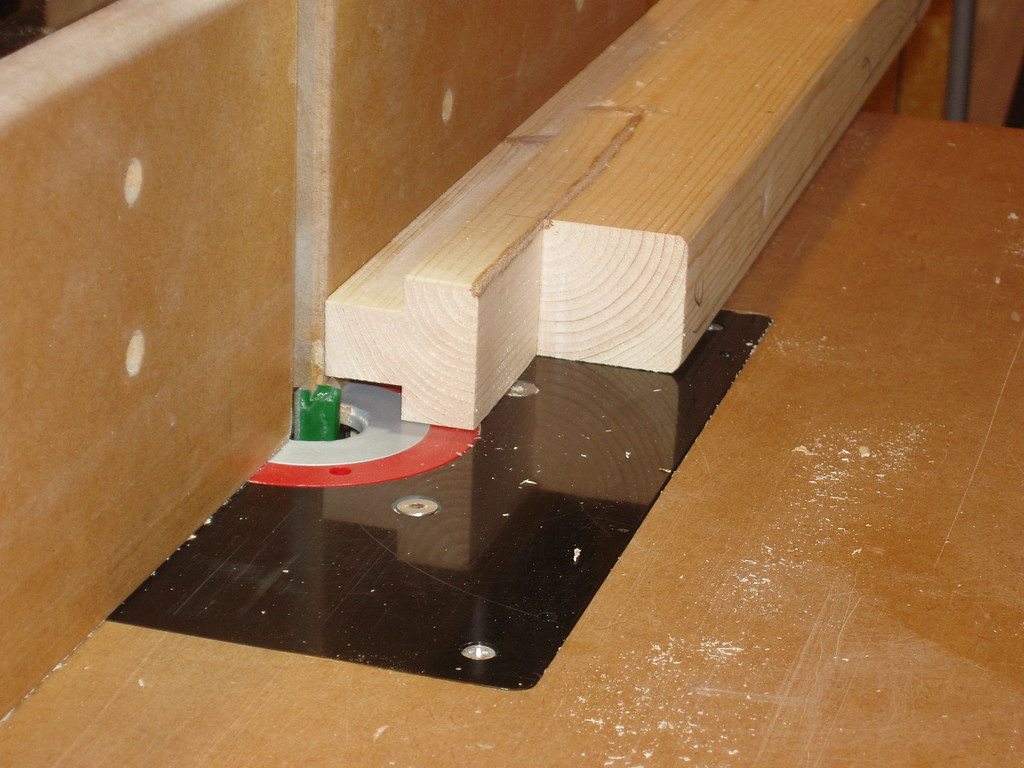

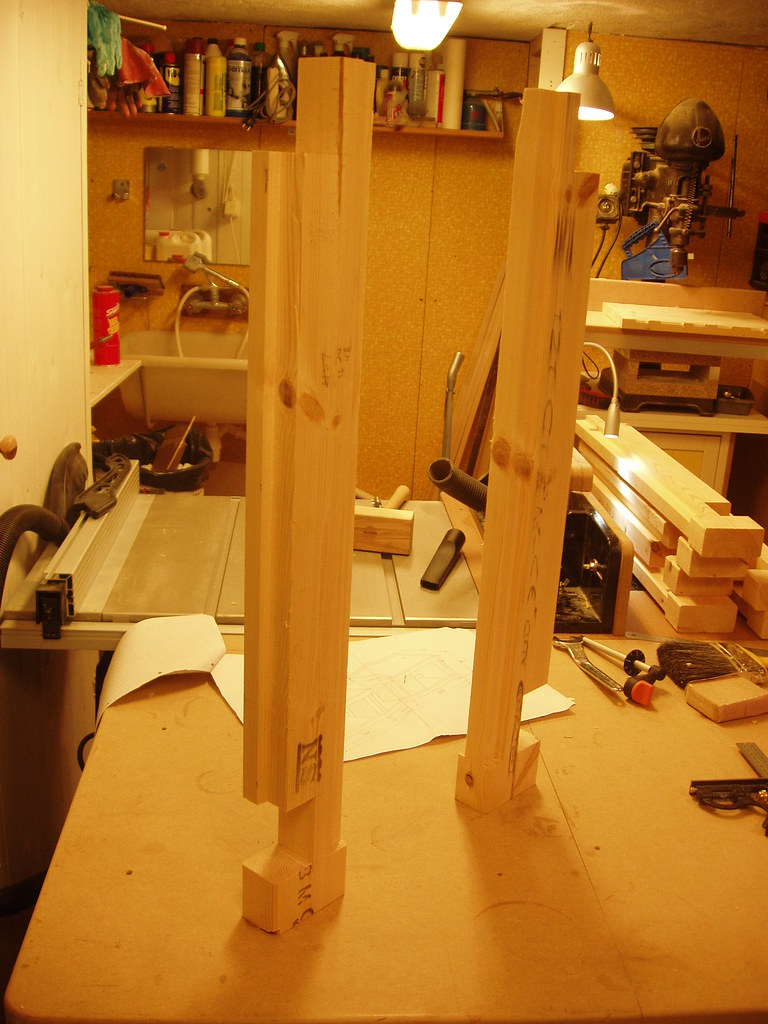

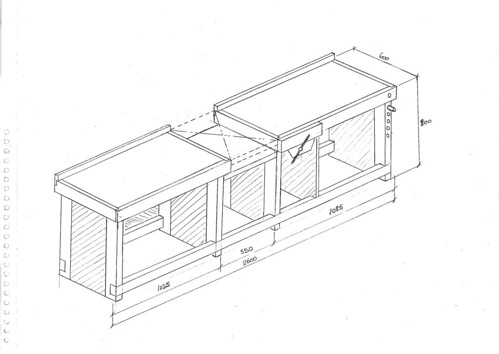

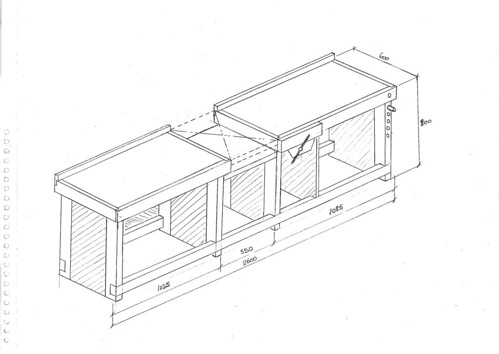

With my very limited space I had to come up with something that was not only small, but also multi-functional. The solution I ended up with was to combine a mitre saw table, vise-bench and storage cupboards in one unit. The construction I’m planning is actually two separate benches joined together by a sunken saw table in the middle. Legs will be 2x4 sandwiched between two layers of 12mm ply. Rails (or are they stretchers ?) from 2x3. Tops; two layers of 19mm MDF lipped with 28mm beech aprons. They’ll be drawers under the vise and cupboard doors on the fronts. They’ll also be backs on the cupboards in 12mm ply to add stability to the whole construction. I’m also planning to make the SCMS quick-detachable and it’ll store in the cupboard directly under and be replaced by a loose bench top section that’ll then give me a flat, continuous worktop when needed.

This will incorporate everything that currently resides along the opposite wall and free up that area for a forthcoming P/T and a whole wall of screw/bolt/odds-n-ends drawers.

Obviously this design is full of compromises, not least of all having the vise only 1 meter from the end of the bench, but hopefully it’ll be a vast improvement on my current setup.

We’ll see ………

Edit - fixed picture sizes.

With my very limited space I had to come up with something that was not only small, but also multi-functional. The solution I ended up with was to combine a mitre saw table, vise-bench and storage cupboards in one unit. The construction I’m planning is actually two separate benches joined together by a sunken saw table in the middle. Legs will be 2x4 sandwiched between two layers of 12mm ply. Rails (or are they stretchers ?) from 2x3. Tops; two layers of 19mm MDF lipped with 28mm beech aprons. They’ll be drawers under the vise and cupboard doors on the fronts. They’ll also be backs on the cupboards in 12mm ply to add stability to the whole construction. I’m also planning to make the SCMS quick-detachable and it’ll store in the cupboard directly under and be replaced by a loose bench top section that’ll then give me a flat, continuous worktop when needed.

This will incorporate everything that currently resides along the opposite wall and free up that area for a forthcoming P/T and a whole wall of screw/bolt/odds-n-ends drawers.

Obviously this design is full of compromises, not least of all having the vise only 1 meter from the end of the bench, but hopefully it’ll be a vast improvement on my current setup.

We’ll see ………

Edit - fixed picture sizes.