Hi

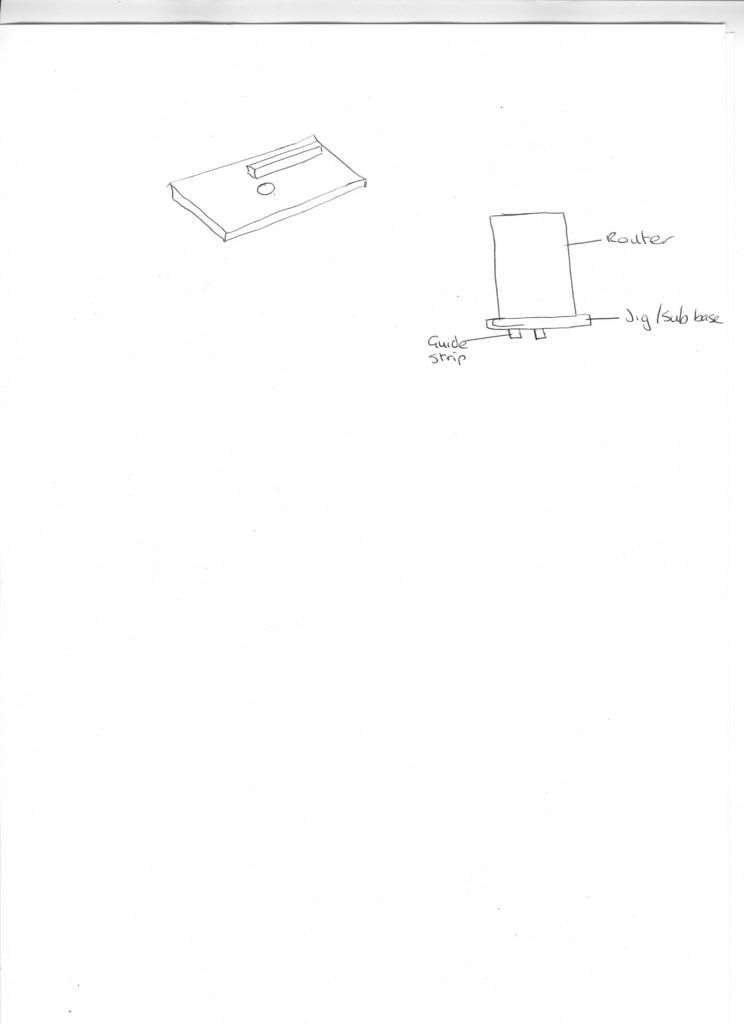

I am looking to join some panels together to make a wall hanging tool cabinet, I plan to use box joints to do this. The panels are 3/4 birch plywood and approx 30 cm wide. I have read about various methods for doing this, the favoured appears to be making a jig for a router table. I have a router but no table. Is it possible to create a template on some thin mdf of the 2 different layouts needed by hand and then clamp these to the workpiece and then use a flush trim bit to create the joints ? I understand I would need to square the bottom of the joint with a sharp chisel. It seems to make sense to me but have not seen this method talked about? Or is this too much hassle and should just cut them all by hand ? Many thanks Richard

I am looking to join some panels together to make a wall hanging tool cabinet, I plan to use box joints to do this. The panels are 3/4 birch plywood and approx 30 cm wide. I have read about various methods for doing this, the favoured appears to be making a jig for a router table. I have a router but no table. Is it possible to create a template on some thin mdf of the 2 different layouts needed by hand and then clamp these to the workpiece and then use a flush trim bit to create the joints ? I understand I would need to square the bottom of the joint with a sharp chisel. It seems to make sense to me but have not seen this method talked about? Or is this too much hassle and should just cut them all by hand ? Many thanks Richard