bodgermatic

Established Member

Shavings are better than screwed up newspapers for starting fires - canvas your friends to see who's got a woodburner or an open fire. I stick a large pile under my kindling, goes up a treat.

bodgermatic":2gh2jize said:Shavings are better than screwed up newspapers for starting fires - canvas your friends to see who's got a woodburner or an open fire. I stick a large pile under my kindling, goes up a treat.

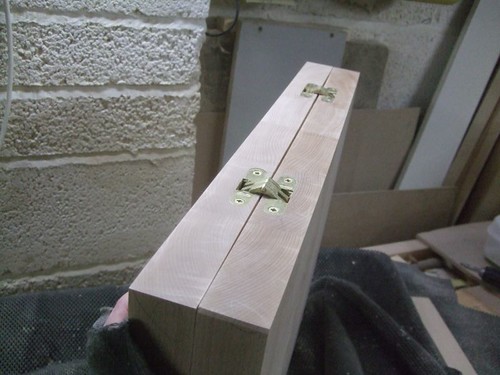

OPJ":8cc7j7sv said:Bad news - I spoke to Isaac Lord today and I'm looking at a three-to-five week wait for the soss hinges I ordered nine-days ago.This definitely won't be finished in time for Christmas dinner, now then. I guess it could get it ready as a four-seater though... Question is, how easy would it then be to get it back to work on?!

OPJ":2w28fbtm said:Has anyone got any tips for checking that you've removed these "invisible" scratches before you apply a finish?

Wiping over the top with whire spirit should darken it up enough to see them, providing you're quick...OPJ":2g3ks1o3 said:I can't be the only person here who uses a belt sander for flattening panels and table tops... Has anyone got any tips for checking that you've removed these "invisible" scratches before you apply a finish? Preferably, answers that don't involve 'lots of extra sanding'!! :wink:

Dammit! The time it took me to read through the post to there you beat mePaul Chapman":2nk2f4q6 said:Keep up, Trim :lol: