oh no! Another workbench build thread!

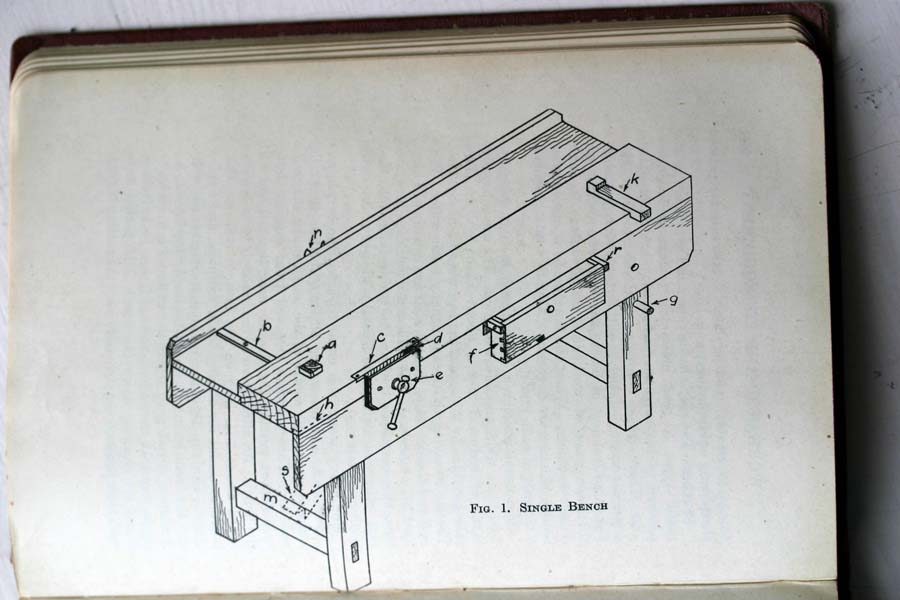

I am having a go at what has become known as an 'English' style bench - I'm not sure why this term became popular, possibly it is down to Chris Schwartz in his (rather good) Workbench book where he identifies three broad traditions in bench design: French (oblong table with a heavy top); English (thin planks on top, one or more aprons); Continental (French + gizmos).

He is a bit snooty about the English design and, despite the fact that he makes it clear the traditions he identifies are very broad generalizations and cover a complex mongrel history, my patriotism was awakened and I resolved to make one myself. That'll show him, I thought!

Actually he does provide a lot of examples from English literature showing this type of design - most famously the one shown in Nicholson's Mechanical Exercises (1812) - and many of us in the UK will have used something similar at school.

The advantage of the design is it is relatively straightforward and you can make it with inexpensive and easily available timber (and you don't need a lot of it). Finally if, like me, you are prepared to stump up £26 you get to follow along with the brilliant Richard Maquire as he tells you how to make it in his top video series:

http://www.theenglishwoodworker.com/new ... workbench/

Having got access to a small pick-up for the near future I was able to get over to the St Albans wood recycling centre last week where they had three boards of 8 1/2'' x 1 3/4'' pine. They were just under 12' ft long - perfect as I only have room for a bench just under 6' (you need 6 lengths - 3 for the top, 2 for the apron and 1 for the top rails). The rest of the bench can be built with 2x4, but I am using a scaffold board I already had.

The pine boards are stamped TR26, which according to the t'internet is some kind of strength grade (>c24). I got a couple of very rough looking 4x4 fence posts also. The total cost was £58 which I thought was good value, at least compared to B&Q prices (is it!?)

I do already have a bench made from plywood in the days when I was still labouring under the false belief that the only way to make things from wood was with machines. It has some limitations that I hope to remedy in the new hand-tool-only bench, the most significant of which is it's location, which is in the darkest corner of the workshop.

It is attached to the wall on two sides, which is both a blessing (very rigid) and a curse (tricky to work with big or awkwardly sized items). it has a small planing stop which I find very useful and will reproduce on the new bench. Perversely, I have also found the absence of an apron very convenient - I had not realized how much I relied on clamps attached to the front lip until I started making the new bench - so using one with an apron should be interesting...

I have nearly finished the legs - only a couple of cock-ups so far, so good progress as far as I'm concerned! will post more pics later.

I am having a go at what has become known as an 'English' style bench - I'm not sure why this term became popular, possibly it is down to Chris Schwartz in his (rather good) Workbench book where he identifies three broad traditions in bench design: French (oblong table with a heavy top); English (thin planks on top, one or more aprons); Continental (French + gizmos).

He is a bit snooty about the English design and, despite the fact that he makes it clear the traditions he identifies are very broad generalizations and cover a complex mongrel history, my patriotism was awakened and I resolved to make one myself. That'll show him, I thought!

Actually he does provide a lot of examples from English literature showing this type of design - most famously the one shown in Nicholson's Mechanical Exercises (1812) - and many of us in the UK will have used something similar at school.

The advantage of the design is it is relatively straightforward and you can make it with inexpensive and easily available timber (and you don't need a lot of it). Finally if, like me, you are prepared to stump up £26 you get to follow along with the brilliant Richard Maquire as he tells you how to make it in his top video series:

http://www.theenglishwoodworker.com/new ... workbench/

Having got access to a small pick-up for the near future I was able to get over to the St Albans wood recycling centre last week where they had three boards of 8 1/2'' x 1 3/4'' pine. They were just under 12' ft long - perfect as I only have room for a bench just under 6' (you need 6 lengths - 3 for the top, 2 for the apron and 1 for the top rails). The rest of the bench can be built with 2x4, but I am using a scaffold board I already had.

The pine boards are stamped TR26, which according to the t'internet is some kind of strength grade (>c24). I got a couple of very rough looking 4x4 fence posts also. The total cost was £58 which I thought was good value, at least compared to B&Q prices (is it!?)

I do already have a bench made from plywood in the days when I was still labouring under the false belief that the only way to make things from wood was with machines. It has some limitations that I hope to remedy in the new hand-tool-only bench, the most significant of which is it's location, which is in the darkest corner of the workshop.

It is attached to the wall on two sides, which is both a blessing (very rigid) and a curse (tricky to work with big or awkwardly sized items). it has a small planing stop which I find very useful and will reproduce on the new bench. Perversely, I have also found the absence of an apron very convenient - I had not realized how much I relied on clamps attached to the front lip until I started making the new bench - so using one with an apron should be interesting...

I have nearly finished the legs - only a couple of cock-ups so far, so good progress as far as I'm concerned! will post more pics later.