johnny.t.

Established Member

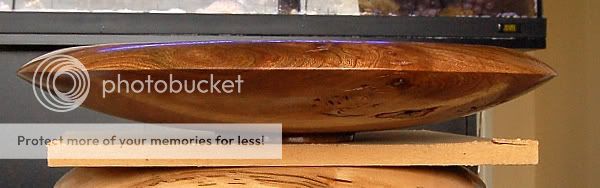

This is a beast of a platter at 14" wide. Thats the maximum over the bed width for my toytown axminster, it was really difficult as out at the edges the machine develops a hell of a lot of vibration, requiring many, many extremely light cuts but I got there in the end  .

.

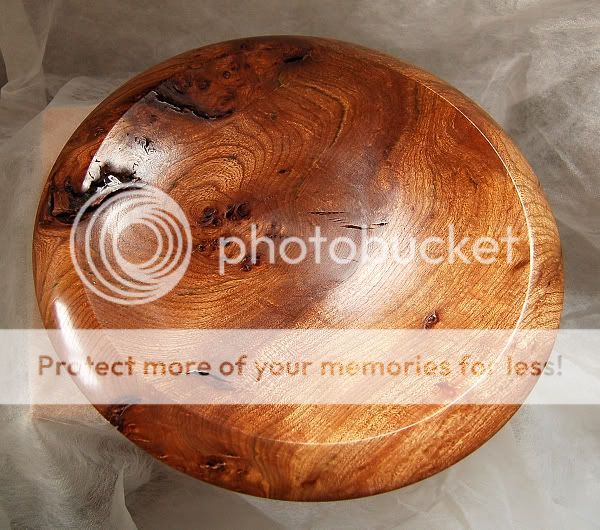

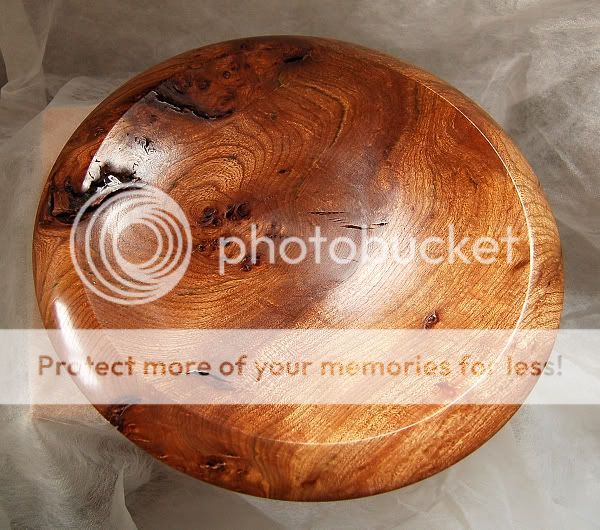

This is the first bit of Elm I've ever turned,I aquired it from a fellow forum member(hope you think I've done it justice) and I must say its gorgeous looking stuff 8).

Anyway I'm hooked on this chunky look at the minute and this is no exception, its a inch thick, with a substantial weight.

It has holes too, just for Wizer :lol:

JT

This is the first bit of Elm I've ever turned,I aquired it from a fellow forum member(hope you think I've done it justice) and I must say its gorgeous looking stuff 8).

Anyway I'm hooked on this chunky look at the minute and this is no exception, its a inch thick, with a substantial weight.

It has holes too, just for Wizer :lol:

JT